Anti-static solutions last longer when they're made with high-quality permanent internal additives rather than temporary surface treatments. You'll get better longevity from materials containing non-migratory additives like Pebax polymers, which form permanent 3D networks within the host polymer. Chemical resistance, molecular structure, and proper storage conditions all play vital roles in durability. Temperature, humidity, and chemical exposure can impact effectiveness, so you'll want to maintain ideal storage conditions between 20-25°C with 40-60% humidity levels. Understanding these factors and implementing proper maintenance techniques can extend your anti-static solution's lifespan from months to years.

Material Quality Determines Longevity

The cornerstone of anti-static solution durability lies in material quality. When you're selecting anti-static materials, you'll need to focus on their chemical resistance and molecular structure, as these factors directly impact how long they'll maintain their effectiveness.

Materials with high chemical resistance won't degrade as quickly when exposed to harsh environments, preserving their anti-static properties for longer periods. Anti-static fillers can affect the material's overall durability and strength over time.

You'll find that the physical characteristics of your chosen material play a vital role in its longevity. The material's elasticity and deformability affect how well it maintains its anti-static properties under stress, while high-temperature resistance guarantees it won't break down in extreme conditions.

Additionally, you'll want to take into account the material's compatibility with other substances it might contact, as incompatible materials can lead to premature deterioration.

For maximum durability, you should look for materials with stable surface resistivity and strong scratch resistance. These properties help maintain consistent static control even with regular use.

Remember that the quality of any additives or conductive fillers in the material will greatly influence its long-term performance, though you'll need to balance this with maintaining the material's overall strength.

Environmental Impact on Performance

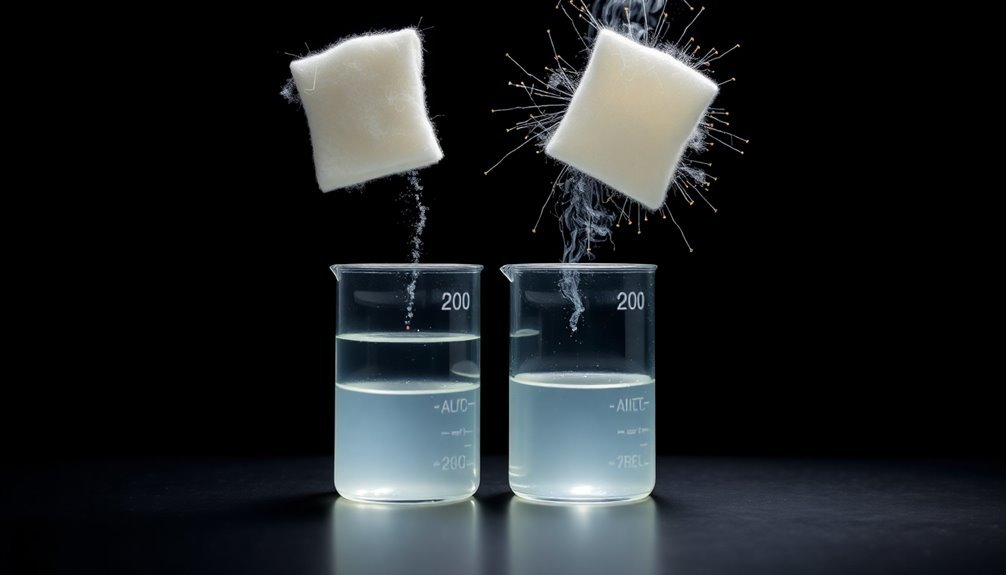

Environmental conditions work directly on anti-static solutions, substantially impacting their effectiveness and longevity. You'll find that temperature extremes and humidity fluctuations play vital roles in how well your anti-static treatments perform.

High humidity can enhance anti-static performance by increasing moisture content, while low humidity reduces effectiveness unless you're using specific additives. Similar to how efficient chemical mixing improves treatment outcomes in wastewater systems, proper humidity levels ensure optimal anti-static performance.

Temperature changes don't just affect immediate performance – they can cause stress-cracking in materials and degrade anti-static agents over time. You'll need to take into account chemical exposure too, as it can compromise your anti-static solution's effectiveness.

When you're selecting anti-static additives, it's worth noting that traditional options like ethoxylated amines raise environmental concerns, but you can opt for plant-based alternatives that offer safer, more sustainable solutions.

To maximize your anti-static solution's lifespan, you'll want to maintain proper storage conditions and conduct regular testing. Modern solutions like Einar® 401 demonstrate better longevity compared to conventional additives. If you're using migratory anti-static masterbatch, you'll benefit from both performance and eco-friendly compliance.

Remember that monitoring and adjusting additive concentrations based on regular static decay testing guarantees the best long-term performance.

Proper Application Techniques

Mastering proper application techniques guarantees your anti-static solutions deliver peak performance and longevity. You'll need to focus on surface treatments, material selection, and static elimination methods to achieve the best results.

When applying chemical treatments, make certain you're incorporating anti-static additives evenly and using appropriate conductive coatings. Chemical stability and durability of HDPE materials make them ideal candidates for long-lasting anti-static treatments.

You'll want to position static eliminators as close as possible to your target material, maintaining adequate free air space for effective neutralization. It's essential to address static charges immediately before problem areas to prevent regeneration.

Your material selection plays a critical role in long-term effectiveness. Choose HDPE with anti-static additives for pipe fittings, or select materials with appropriate surface and volume resistivity levels for your specific application. You'll need to evaluate both conductive and dissipative materials based on your requirements.

Don't forget to comply with regulatory standards and conduct proper testing. You should perform surface and volume resistivity tests using methods like ASTM D257 to comply.

Remember to cool materials to a stable temperature before neutralization and adjust your anti-static measures according to your application's specific requirements.

Storage and Handling Best Practices

Proper storage and handling practices build upon your application techniques to maximize the lifespan of anti-static solutions.

You'll need to maintain strict environmental controls, keeping temperatures between 20-25°C and humidity levels at 40-60% to prevent degradation of anti-static properties.

Store your anti-static solutions in ESD-safe containers and place them on grounded, static-dissipative surfaces. Don't use regular plastic containers or place items on carpeted areas, as these generate unwanted static electricity.

You'll want to implement a vertical storage system with clearly labeled containers for efficient inventory management and easy access. Standardized naming conventions help ensure consistent organization of components.

When handling anti-static materials, always wear ESD-safe clothing and use anti-static tools. Make sure you're properly grounded with wrist straps and mats before touching any components.

You should regularly inspect your storage facilities and conduct maintenance checks on all ESD protection equipment.

Consider implementing an advanced inventory tracking system to monitor your anti-static solutions' storage conditions and shelf life.

Train your staff in proper handling techniques and guarantee they follow lean warehousing principles.

Regular cleaning of storage areas prevents dust accumulation that could compromise the effectiveness of your anti-static solutions.

Chemical Structure Matters

The chemical structure of anti-static additives invariably determines their long-term performance and durability. When you're selecting an anti-static solution, you'll find that non-migratory additives, like Pebax polymers, offer superior longevity by forming permanent 3D networks within the host polymer.

These networks create continuous pathways for static dissipation that won't degrade over time. Unlike traditional solutions, they maintain effectiveness with no sloughing or blooming.

You'll get the best results from high molecular weight polymers and inherently dissipative polymers (IDPs), as they establish a co-continuous ion conductive phase that remains stable throughout the product's lifecycle. The key lies in block copolymer chemistry, where polyether blocks provide flexibility and chemical channeling, while polyamide blocks contribute toughness and chemical resistance.

To achieve top performance, you'll need to guarantee the additive concentration reaches a critical threshold that creates a complete static-dissipating molecular network. However, you must also consider compatibility with your host polymer – the additive shouldn't compromise the material's physical properties, color, or strength.

When properly engineered, these structural elements work together to deliver long-lasting anti-static protection that meets industry standards and regulatory requirements.

Temperature and Humidity Effects

Understanding temperature and humidity's dual impact on anti-static solutions can make or break your static control strategy. When temperatures drop, you'll notice your anti-static treatments become less effective as cold air holds less moisture, leading to increased static buildup. This is particularly challenging in northern climates during winter months, where indoor heating systems further reduce humidity levels. Charges leak to ground more effectively in properly humidified environments.

Conversely, high temperatures don't automatically solve static problems. In hot, dry climates like Phoenix or Las Vegas, you'll still face static electricity challenges without proper humidity control.

The key lies in maintaining relative humidity between 40-60%, as humidity levels below 30% can generate dangerous static charges up to 35,000 volts.

- Your expensive electronics could be destroyed in milliseconds by an uncontrolled static discharge

- You're risking workplace safety when humidity drops below critical levels

- Your manufacturing processes might fail during seasonal temperature changes

- Your anti-static solutions won't protect you if environmental conditions aren't properly managed

To maximize your anti-static solution's durability, you'll need to monitor both temperature and humidity. Consider using evaporative humidification systems to maintain ideal conditions, especially in challenging climates where natural humidity levels fluctuate dramatically.

Testing Methods and Standards

You'll need to understand key industry standards like ASTM D257 and ESD ADV1.0-2017 to properly evaluate anti-static solutions.

Testing tools, including surface resistivity meters and volume resistivity test equipment, help you measure a material's ability to dissipate static charges.

Running compliance tests according to standards like ANSI/ESD S20.20 and IEC 61000-4-2 guarantees your anti-static solutions meet required specifications for their intended applications. Static decay tests provide critical data by measuring the time it takes for a 5kV charge to dissipate to 10% of its initial value.

Key Industry Standards

Encompassing multiple testing methodologies, industry standards for anti-static solutions rely on specific measurements and benchmarks to guarantee consistent performance.

You'll find that standards like ANSI/ESD STM11.11 specify surface resistance requirements between 10^6 and 10^9 ohms, while ANSI ESD S20.20 provides detailed guidelines for ESD control programs. Moisture barrier bags can protect components in high-humidity environments while maintaining ESD protection standards.

When you're evaluating anti-static solutions, you'll encounter three main material categories: anti-static (10^10 to 10^12 ohms), static dissipative (10^4 to 10^11 ohms), and conductive (less than 10^4 ohms). Testing methods like frictional charging voltage measurement and triboelectric charge measurement help determine a material's effectiveness.

You can't afford to risk your sensitive electronics with subpar ESD protection.

Your facility's safety depends on maintaining proper resistance levels.

Your investment in quality anti-static solutions protects valuable equipment.

Your compliance with standards like IEC 61340-5-1 safeguards your operations.

For ESD flooring specifically, standards require resistance between 1 million and 100 million ohms, with the ability to dissipate a 5000V charge to less than 50 volts within 2 seconds. Regular testing confirms these standards continue to be met over time.

Testing Tools Overview

Modern testing tools form the backbone of quality assurance in anti-static solutions development. You'll find that automated static testing tools like BrowserStack Code Quality, SonarQube, and ESLint help guarantee your anti-static solutions meet rigorous quality standards. These tools scan your code for potential vulnerabilities, coding standard violations, and common programming mistakes without human intervention.

When you're developing anti-static solutions, you'll need multi-dimensional scanning capabilities and real-time feedback. Tools like OWASP Dependency-Check and Fortify can identify security issues.

While developing, you'll benefit from integration with CI/CD pipelines, which automates quality checks and catches issues early in development.

To maximize your solution's durability, you'll want to use specialized tools like Checkmarx to scan for vulnerabilities such as SQL injection and cross-site scripting. SonarQube helps you detect bugs, duplicate code, and performance issues, while Pylint confirms adherence to coding standards.

These tools integrate seamlessly with version control systems and provide IDE plugins, making it easier to maintain high-quality code throughout development.

Compliance Test Procedures

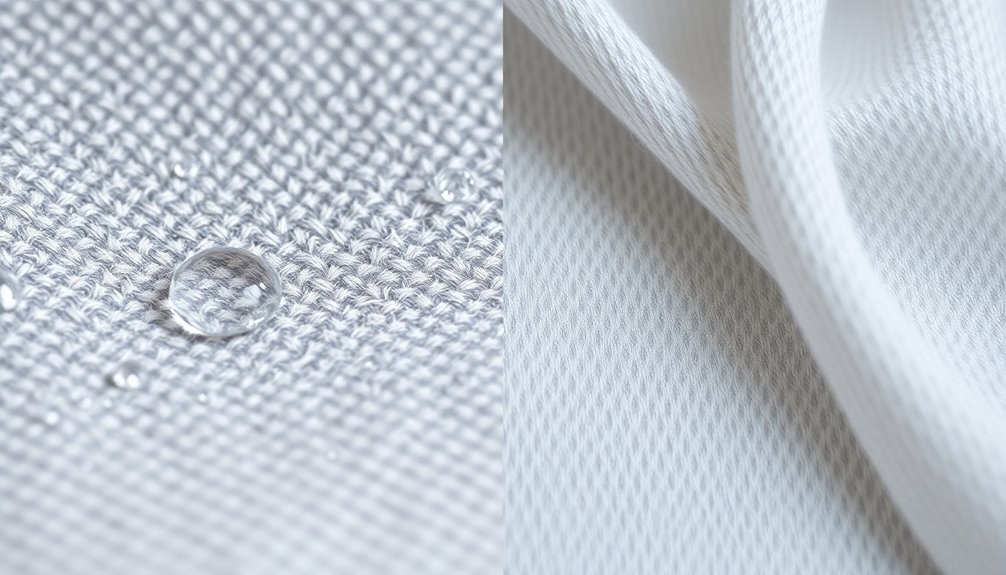

Three essential compliance standards govern anti-static solution testing: ANSI/ESD S4.1, EN 1149, and ASTM D257. These standards require specific test methods to assess how well materials dissipate static charges, with surface resistivity being the most critical measurement. You'll need to use specialized ESD meters and electrodes to conduct these tests properly, ensuring good contact between the sample and testing equipment.

When you're testing anti-static garments under EN 1149-5, your material must achieve a surface resistance below 2.5 x 10^9 Ohms or demonstrate adequate charge decay properties.

You'll need to take into account environmental factors like humidity and surface contamination, as they can markedly impact your test results.

- Feel confident knowing your anti-static solution meets rigorous international safety standards

- Trust in the precision of electrode-based measurements over less reliable point probes

- Rest assured that dual testing methods (resistance and charge decay) provide thorough protection

- Take comfort in the fact that certified solutions have undergone extensive performance verification

Remember to test under specified humidity conditions and maintain clean testing surfaces for accurate results. Different applications may require specific test methods, so always verify which standards apply to your particular use case.

Maintenance Requirements Over Time

Maintaining anti-static solutions requires a systematic approach that evolves with usage patterns and environmental conditions. You'll need to adapt your cleaning frequency based on your specific process environment and the level of contamination your devices experience.

Regular cleaning isn't just about maintenance—it's essential for preventing performance degradation and extending device lifespan.

When you're cleaning anti-static devices, you'll need to use specialized non-conductive, water-free solvents that evaporate without leaving residue. You should pay particular attention to emitters and pins, using specially designed brushes and cloths to avoid damage. Don't forget to polish the pins with a dry cloth after cleaning.

The longevity of your anti-static solution depends largely on your choice between internal and external agents. You'll find that internal additives typically last longer than external coatings, while migratory agents may lose effectiveness over time.

Consider your environment's humidity and temperature levels, as these factors substantially impact performance duration. When you're selecting an anti-static solution, evaluate your application's specific requirements to choose between permanent and temporary options. This decision will directly influence your long-term maintenance needs and overall system efficiency.

Surface Preparation and Coverage

Proper surface preparation stands at the foundation of any effective anti-static solution deployment. When you're applying anti-static treatments, you'll need to guarantee your surfaces are free from contaminants to achieve ideal adhesion and uniform coverage.

This critical step not only enhances the durability of your solution but also guarantees efficient distribution of anti-static agents across the treated area.

Different surfaces require specific preparation methods and compatible solutions. You'll find that water-based solutions work well for most applications, providing even coverage and ease of use. For industrial applications, liquid anti-static agents deliver consistent results, while powder forms excel in dry processing environments.

Your choice of application method – whether spray, roller, or dip – will substantially impact the solution's performance and longevity.

Your product's safety and reliability depend on thorough surface preparation – don't risk equipment failure.

You're investing time now to prevent costly static-related accidents later.

Your facility's reputation hinges on maintaining proper anti-static protection.

You'll sleep better knowing you've taken every precaution to protect your sensitive electronics.

The surface's electrical resistance properties will determine which anti-static solution you'll need, with highly resistant materials requiring more robust treatments for effective performance.

Grounding and Conductivity Principles

Reliable grounding and conductivity systems form the cornerstone of effective anti-static protection. When you're dealing with static electricity, you'll need to guarantee proper grounding connections that maintain a resistance of 1 megaohm or less to effectively drain static charges to the earth.

Your grounding system's success depends on implementing the right combination of wires, clips, and clamps to connect conductive materials.

Conductivity plays a vital role in how long your anti-static solutions last. Materials with surface resistivity less than 1 x 10^5 Ω/sq will conduct electricity more effectively, preventing dangerous charge build-up.

By bonding conductive objects together, you're creating an equalized electrical potential that prevents sparking between surfaces.

To maximize the longevity of your anti-static protection, you'll need to combine proper bonding and grounding with environmental controls. While higher humidity can help dissipate charges, don't rely on it alone.

You should incorporate antistatic agents and guarantee your flooring and footwear meet static-dissipative requirements.

Monitor your systems regularly through process control equipment to confirm your grounding connections remain effective and maintain their protective properties over time.

Protective Coating Considerations

The longevity of anti-static protection heavily depends on your choice and application of protective coatings. When you're applying protective coatings, you'll need to guarantee proper surface preparation and maintain adequate coating thickness for peak performance.

Your coating's effectiveness will last longer if you've selected materials that are chemically stable and inherently conductive, as these properties help resist degradation over time.

You can substantially extend your anti-static solution's lifespan by implementing protective measures that shield against environmental stressors. It's vital to control temperature and humidity levels while protecting the coating from excessive friction and electromagnetic interference.

Regular cleaning and maintenance of the protective coating will help preserve its conductive properties and prevent the buildup of performance-degrading pollutants.

- Don't let your sensitive electronics become vulnerable to static damage due to worn-out coatings

- Protect your investment by choosing high-quality protective materials from the start

- Save time and money by preventing coating failures before they occur

- Secure your operations by maintaining peak coating performance through proper care

Remember to take into account composite materials and advanced processing technologies when selecting your protective coating, as these can enhance the overall stability and durability of your anti-static solution.

Frequently Asked Questions

Can Anti-Static Solutions Be Used on Fabric and Clothing Effectively?

Yes, you can effectively protect your clothing with anti-static solutions through woven conductive threads or surface treatments. You'll find both permanent options like carbon-threaded fabrics and temporary solutions like spray-on treatments.

Do Electronic Devices Near Anti-Static Surfaces Affect Their Performance?

When you place electronics near anti-static surfaces, they'll actually perform better since these surfaces protect your devices from harmful static discharge while maintaining proper grounding, preventing potential damage and interference.

Are There Natural Alternatives to Synthetic Anti-Static Solutions?

Yes, you can use vinegar in your rinse cycle, wool dryer balls, soap nuts, and aluminum foil balls as natural anti-static alternatives. You'll also find that hang-drying clothes and using humidifiers effectively reduces static.

How Do Different Metals React With Anti-Static Treatments?

You'll find that aluminum and copper readily accept anti-static treatments due to their high conductivity. Stainless steel needs specific coatings, while titanium requires specialized treatments because of its lower natural conductivity.

Can Anti-Static Solutions Cause Allergic Reactions in Sensitive Individuals?

Yes, you can experience allergic reactions to anti-static solutions, especially those containing ethoxylated amines. You'll notice symptoms like itching, rashes, and inflammation. Consider using plant-based alternatives to prevent these reactions.

In Summary

You'll find that the longevity of your anti-static solution depends on multiple factors working together. Quality materials, proper application, and good environmental conditions create longer-lasting protection. If you're aiming for extended performance, focus on thorough surface preparation, use solutions with stable chemical structures, and maintain appropriate storage practices. Don't forget that regular maintenance and correct grounding techniques will help your anti-static protection endure.

Leave a Reply