Moisture barrier shield bags protect your electronics through a sophisticated three-layer defense system. You'll find static dissipative polyester on the outside, acting as a Faraday cage against electrostatic discharge. The middle aluminum shield layer controls moisture vapor, while the inner polyethylene layer adds another static barrier and enables heat sealing. Together, these layers maintain surface resistance of 10⁸ to 10¹¹Ω and block water vapor penetration, meeting strict military and industry standards. You can enhance this protection with desiccants and humidity indicator cards. The advanced engineering behind these protective bags goes even deeper.

The Three-Layer Defense System

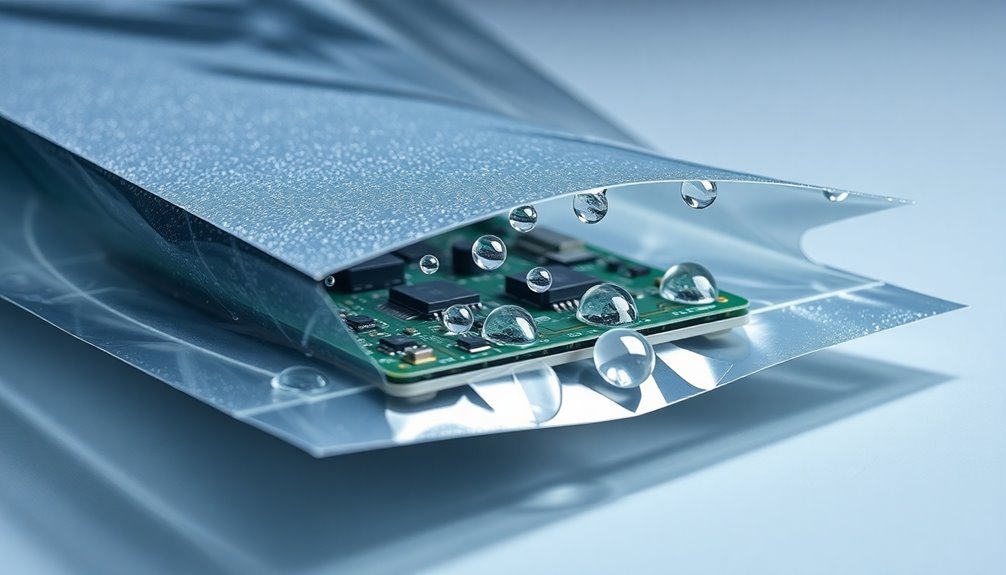

A fortress of protection surrounds sensitive electronics inside moisture barrier shield bags. You'll find three distinct layers working together to create an impenetrable shield against harmful elements that could damage your components.

The outer layer features a static dissipative polyester surface that's both opaque and light-fast. This first line of defense acts as a Faraday cage, protecting your electronics from electrostatic discharge while preventing anyone from viewing the contents. The bags maintain a surface resistance of 10⁸ to 10¹¹Ω, ensuring consistent static protection.

In the middle, you'll discover an aluminum shield layer that's essential for controlling moisture vapor transmission. This aluminum barrier guarantees your electronics stay dry by preventing water vapor from penetrating the bag, meeting strict IPC/JEDEC J-STD-033 requirements.

The innermost layer consists of static dissipative polyethylene, adding another level of protection against electrostatic discharge. Its flexible structure allows for effective vacuum and heat sealing, creating a complete moisture-proof barrier.

Together, these three layers form a thorough defense system that's puncture-resistant and can be customized to your needs. When you're shipping electronics, especially by sea, you can enhance this protection further by adding desiccants and humidity indicator cards.

Essential Protection Materials

Advanced moisture barrier shield bags incorporate multiple protective layers, including metallized films, static dissipative coatings, and reinforced barriers working together as a unified defense system.

The strategic combination of aluminum shield layers with static dissipative materials creates a robust barrier against moisture vapor transmission and electrostatic discharge while maintaining flexibility. Three-layer construction provides optimal protection through static dissipative polyester, aluminum, and polyethylene layers.

These specialized materials, from the metallized film technology to the heat-sealable inner layers, give you thorough protection for sensitive electronic components through their synergistic properties.

Multi-Layer Defense Construction

Three essential layers form the backbone of moisture barrier shield bags, each serving a distinct protective purpose for sensitive electronics. You'll find a static dissipative surface layer, a metal shield center (typically aluminum), and a static dissipative bottom layer working together to create extensive protection.

These layers combine to shield your components from electrostatic discharge while controlling moisture through specialized MVTR management. The bags maintain effectiveness across a wide temperature range from -20 to 160 °F.

The construction's effectiveness relies on carefully selected materials like polyester, aluminum, and polyethylene, each chosen for specific protective properties. You'll often see variations using Tyvek or aluminized polyester, offering additional strength and moisture resistance.

When you're dealing with sensitive electronics, these bags provide:

- ESD protection through multiple static dissipative layers

- Moisture control with specialized barrier properties

- Heat-sealing capability for secure closure

- Vacuum packaging compatibility for minimal air exposure

- Clear construction options for visual inspection

You can trust these multi-layer bags for various applications, from storing SMT components to protecting military-grade electronics. They're particularly valuable in high-tech manufacturing environments where moisture and static damage prevention is vital for maintaining component integrity.

Barrier Material Properties

Selecting the right barrier materials proves essential for protecting sensitive electronics from environmental threats. You'll find various material compositions designed to provide thorough protection, from three-layer constructions featuring nylon/foil/poly to advanced four-layer systems incorporating static dissipative coatings.

The effectiveness of these barriers largely depends on their moisture vapor transmission rate (MVTR), with metallised bags offering the lowest rates and meeting IPC/JEDEC J-STD-033 standards. The military-grade packaging meets strict DOD specifications for maximum protection against water vapor and oxygen intrusion.

You'll notice that bags with superior moisture protection require less desiccant loading, which extends dry storage time. The aluminized metal layer doesn't just block moisture; it also provides critical discharge shielding and minimizes electric field penetration.

These bags' physical properties guarantee durability and functionality. They're puncture-resistant yet flexible enough for easy handling.

You can rely on their heat-sealable nature for secure vacuum packaging, while their opaque construction prevents light damage. The materials comply with RoHS standards and provide ESD shielding protection according to ANSI/ESD STM11.31.

For maximum protection, they offer 10db EMI attenuation tested up to 10 GHZ, guaranteeing your electronics remain safe from multiple environmental threats.

Metallized Film Technology

Throughout modern electronics protection, metallized film technology stands as a cornerstone solution, combining barrier protection, thermal insulation, and reflectivity in a single material.

You'll find this technology at work in moisture barrier shield bags, where a thin metallic coating on flexible plastic film creates a highly effective protective barrier. The process relies on physical vapor deposition to create the metallized layer. When you're storing or shipping sensitive electronic components, metallized films work to shield against moisture, oxygen, and environmental contaminants.

- Vacuum metallized films deliver superior barrier properties through precise metal deposition

- Aluminum metallized options provide exceptional thermal insulation and moisture protection

- Metallized polypropylene combines high tensile strength with reliable heat sealability

- Polyester metallized variants offer enhanced durability and chemical resistance

- Multiple layer configurations available to meet specific protection requirements

The functionality of metallized films in electronics packaging isn't just about barrier protection. You're also getting thermal insulation that helps maintain stable conditions for your components, while the reflective surface adds another layer of protection against light and radiation.

This technology's versatility and effectiveness make it an ideal choice for creating moisture barrier shield bags that protect your valuable electronic investments.

Static Discharge Prevention Technology

The multi-layer construction of moisture barrier shield bags works through precisely engineered static defense mechanisms, including aluminum shielding and static-neutralizing materials.

You'll find conductive materials integrated throughout the bag's structure, creating a Faraday cage effect that blocks external electrical interference while safely dissipating internal charges. Static charges up to 25,000V can accumulate in electronic components without proper protection.

The bag's specialized layers actively weaken electrostatic fields through a combination of absorption and neutralization, ensuring your sensitive electronic components remain protected from potentially damaging static discharge.

Multi-Layer Static Defense

Modern static discharge prevention relies on sophisticated multi-layer static defense technology, which combines specialized materials to create an impenetrable shield against electrostatic discharge (ESD). You'll find these protective layers working together, with surface resistivity ranging from 10^4 to 10^6 ohms/square, to effectively block and dissipate static charges that could damage your sensitive electronics.

When you're handling critical components in aerospace, medical, or automotive applications, you can't risk ESD damage. The multi-layer defense system creates a controlled environment that neutralizes internal charges while blocking external static fields. This protection is vital since latent damage effects can lead to intermittent performance issues over time.

You'll need to maintain proper handling and storage conditions to guarantee the packaging's effectiveness.

- Prevents both immediate and latent ESD damage to extend component life

- Creates a controlled environment with proven static dissipation properties

- Meets industry standards for protecting static-sensitive components

- Offers versatile protection in various forms, including bags and boxes

- Maintains component integrity through multiple protective layers

To maximize protection, you'll want to regularly inspect the packaging material and guarantee proper sealing techniques. The system's effectiveness relies on maintaining the integrity of each layer while providing safe static charge dissipation pathways that protect your valuable electronic components.

Conductive Material Integration

Integrating conductive materials into protective packaging creates a robust defense against static discharge threats. When you're handling sensitive electronic components, you'll find that these materials, including conductive silicones and carbon-filled polymers, actively neutralize static charges by providing a path to ground.

This integration is vital for preventing potentially damaging electrostatic discharge events that could compromise your components' functionality.

You'll discover that these conductive materials aren't just passive barriers; they're engineered specifically for high-density packaging and high-speed data transfer applications. Products like DOWSIL EC-6601 offer both strong adhesion and reliable conductivity, ensuring your electronics remain protected throughout storage and transport.

The materials' high shielding effectiveness against electromagnetic interference adds another layer of protection for your sensitive devices.

When you're working with IoT devices, automotive systems, or 5G communications equipment, you'll need this level of protection to maintain component integrity. The conductive materials work continuously to dissipate static charges, preventing charge buildup that could lead to component failure.

This protection is essential in maintaining the quality and reliability of your electronic products throughout their lifecycle.

Electrostatic Field Dissipation

Effective static discharge prevention requires a holistic approach to electrostatic field dissipation in moisture barrier shield bags. These specialized bags incorporate advanced materials and design features that work together to neutralize static charges and protect sensitive electronic components.

Proper ESD protection is achieved through the integration of antistatic materials that create equipotential surfaces, effectively preventing charge accumulation and unwanted discharge events.

- TVS diodes and varistors embedded in the bag's structure absorb excess static electricity

- Low-charging materials actively neutralize static charges upon contact

- Multiple layers work together to create consistent charge distribution

- Conductive elements guarantee proper grounding and charge dissipation

- Strategic impedance optimization forces ESD current to ground

When you're handling electronic components, these bags work in conjunction with other ESD control measures like wrist straps and grounding mats. The bags' design considers the entire ESD protection ecosystem, including the optimization of discharge paths and the reduction of electromagnetic interference.

Moisture Vapor Control Methods

Several proven methods exist for controlling moisture vapor in electronic components and assemblies. You'll find silica gel desiccants are particularly effective, as they can absorb up to 40% of their weight in moisture. These desiccants work by creating a dry environment inside your packaging, preventing moisture-induced failures in sensitive electronics.

When you're dealing with very low humidity requirements, you'll want to think about molecular sieve desiccants. They're specifically designed for applications where maintaining extremely dry conditions is vital.

For additional protection, you can use moisture barrier bags that combine multiple layers of aluminum, polyester, and nylon to create a controlled atmosphere with low relative humidity.

You'll also benefit from protective coatings and potting compounds. Materials like MBS-CR silicone provide excellent moisture resistance while offering additional protection against shock and vibration. These coatings don't just shield against moisture – they're self-catalyzed and maintain their electrical properties even in challenging conditions.

When you combine these methods – desiccants, barrier bags, and protective coatings – you'll create a thorough moisture control system that effectively protects your electronic components from corrosion and failure.

Military-Grade Construction Standards

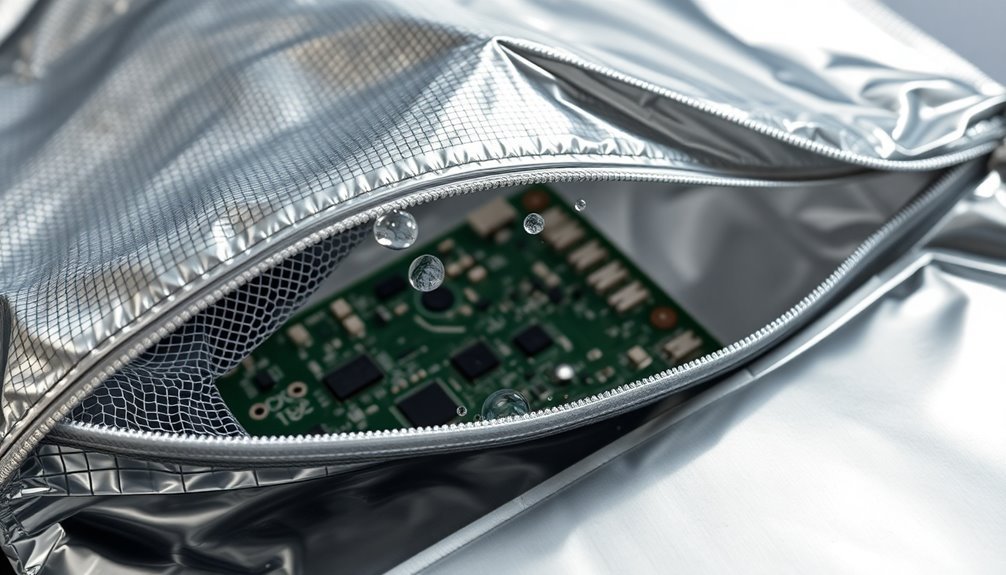

Quality construction lies at the heart of military-grade moisture barrier shield bags. You'll find these bags are built with multiple layers of high-density polyethylene, nylon, paper, and aluminum foil, creating an impenetrable shield against environmental threats.

When you're protecting sensitive electronics, these materials work together to block moisture, dust, and electrostatic discharge while maintaining their integrity under extreme conditions.

The military-grade construction guarantees you're getting maximum protection through:

- Advanced multi-layered designs that deliver superior puncture resistance

- Low Moisture Vapor Transmission Rate (MVTR) that meets IPC/JEDECJ-STD-033 requirements

- Heat-sealable materials that create a complete protective environment

- Chemical and environmental resistance for long-term storage reliability

- Built-in electrostatic discharge protection that meets EIA standards

You can rely on these bags for your most sensitive components, as they're specifically engineered for aerospace, defense, and electronics applications. They're traceable through printed lot codes and warning symbols, guaranteeing you maintain quality control throughout your storage and shipping processes.

Whether you're storing surface mount devices or other moisture-sensitive electronics, these bags provide the military-grade protection you need.

Customization and Flexibility Features

Moisture barrier shield bags' adaptable design puts customization at your fingertips. You'll find these bags can be tailored to your specific needs, from size and material composition to specialized formats like bottom gusset and vertical heat seal options. Whether you're protecting sensitive electronics or military equipment, you can choose from materials like Nylon/Foil/Poly or Tyvek/Foil/Poly combinations.

| Feature | Benefit |

|---|---|

| Multiple Sizes | Fits various product dimensions perfectly |

| Material Options | Matches protection level to application |

| Sealing Methods | Choose between heat, vacuum, or zip sealing |

| Custom Printing | Add your branding and handling instructions |

| Reusable Designs | Save costs with multi-use options |

You'll appreciate how these bags work seamlessly with automatic sealing machines, cutting packaging time by up to 50%. The custom-fit approach eliminates excess material waste and reduces overall packaging costs. When you need quick solutions, many options can be dispatched within 24 hours. Your electronics receive superior protection through features like static dissipation, puncture resistance, and light protection, while the moisture barrier shield maintains ideal conditions for sensitive components.

Environmental Impact Resistance

Engineered with multiple protective layers, these shield bags deliver extensive defense against diverse environmental threats.

You'll find robust materials like polyester, nylon, and polyethylene working together with aluminum layers to create an impenetrable barrier against moisture vapor and static discharge. These bags maintain a controlled environment below 38% relative humidity, protecting your sensitive electronics from corrosion and damage.

- Multilayer construction combines polyester/foil/poly and aluminized polyester/poly for maximum protection

- Metal barrier layers block moisture vapor while minimizing electric field penetration

- Static dissipative coatings prevent dangerous electrostatic discharge through Faraday Cage effect

- Puncture and tear-resistant materials guarantee durability during shipping and storage

- Heat-sealable design enables vacuum packaging for enhanced protection

The bags' physical durability guarantees your electronics remain safe during transport and storage, while the flexible structure makes handling easy.

You can enhance the protection by adding desiccants inside the bags to absorb any residual moisture. The bags' static dissipative properties prevent static buildup and discharge, creating a complete shield that protects your sensitive components from both moisture and electrical threats.

Industry Applications and Benefits

The versatile protection of shield bags makes them indispensable across multiple industries, from electronics manufacturing to aerospace and military applications. You'll find these bags protecting sensitive electronic components like semiconductors, printed circuit boards, and memory cards, especially in high-humidity environments during maritime shipping.

When you're operating in industries with strict packaging standards, such as military or aerospace, you can rely on moisture barrier bags to maintain equipment integrity. They'll create a controlled atmosphere with less than 38% relative humidity, while their aluminum layers provide the lowest water vapor transmission rates among flexible materials.

You can customize these bags for specific applications, reducing waste and sealing time by up to 50% compared to standard packaging. They're particularly effective when combined with desiccant bags and humidity indicator cards for maximum protection.

By using moisture barrier bags, you'll minimize the risk of costly repairs or replacements due to moisture damage, making them a cost-effective solution for your business.

The bags' multi-layer construction, featuring materials like aluminum, polyester, and polyethylene, guarantees you'll get both strength and flexibility while maintaining protection against moisture vapor and oxygen corrosion.

Frequently Asked Questions

What Is the Average Lifespan of a Moisture Barrier Shield Bag?

You'll find that moisture barrier shield bags don't have a set lifespan, but they'll maintain their protective properties as long as you properly store them and avoid damage to their layered materials.

Can Moisture Barrier Bags Be Reused After Initial Vacuum Sealing?

You shouldn't reuse moisture barrier bags after initial vacuum sealing. They're designed for single use, as opening can damage barrier properties, compromise seals, and reduce desiccant effectiveness, potentially risking your electronic components.

How Do Temperature Fluctuations Affect the Bag's Protective Properties?

Temperature fluctuations can weaken your bag's protective layers, risking condensation formation inside. You'll find that extreme changes might affect the MVTR rate and compromise the moisture barrier's effectiveness during temperature shifts.

What Cleaning Methods Are Safe for Moisture Barrier Shield Bags?

You'll want to use gentle methods like dry, soft cloths or light vacuum suction. Don't use chemicals, water, or abrasive materials. Stick to careful wiping to remove surface dirt, avoiding harsh cleaning techniques.

Are There Specific Storage Requirements for Unused Moisture Barrier Bags?

You'll need to store unused moisture barrier bags in dry, sunlight-free areas with controlled temperatures. Keep them in airtight containers, avoid compression, and regularly inspect for damage to maintain their protective properties.

In Summary

You'll find that moisture barrier shield bags protect your electronics through multiple sophisticated layers working together. They combine metal foil, specialized polymers, and anti-static materials to block moisture, prevent static discharge, and shield against electromagnetic interference. When you're storing or shipping sensitive components, these bags' military-grade construction standards guarantee your electronics remain safe from environmental threats and physical damage.

Leave a Reply