To calculate overhead ionizer coverage for your workspace, start by measuring the total square footage, multiplying the room's length by width. You'll need 2-3 fans for standard workstations covering 2×3 ft to 4×5 ft areas. Mount units 12-24 inches above work surfaces, ensuring proper clearance for ideal ion distribution. Consider fixed elements like columns and fixtures that might affect placement, and factor in high-traffic areas when planning coverage. For best results, maintain stable temperature and humidity levels while following ANSI/ESD S20.20 standards. Our detailed guide will help you maximize your ionizer's performance through proper planning and placement.

Understanding Overhead Ionizer Coverage Areas

Through proper understanding of overhead ionizer coverage areas, you'll guarantee effective static control across your workspace. Standard coverage areas typically span 2'x4', though some models offer 2'x3' configurations. When selecting your ionizer, you'll need to match these dimensions to your specific workstation requirements. Low offset voltage of ±10 volts ensures optimal neutralization of static charges. Three fan systems deliver superior air distribution for comprehensive coverage.

You can expect discharge times of less than 3 seconds at 18" distance and less than 6 seconds at 24" with fast decay capabilities. The ionization technology you choose matters – AC technology provides balanced ion output, while DC ionization offers an alternative in models like the SCS Ion Pro.

Your overhead ionizer should include essential safety and efficiency features. Look for units with integrated task lighting to improve visibility while maintaining energy efficiency. Built-in emitter point cleaners and safety switches will guarantee safe maintenance procedures.

When evaluating options, verify that the unit comes factory calibrated with a certificate.

To maximize effectiveness, consider that pure tungsten emitters are strategically spaced to minimize ion recombination. You'll find most models are designed to meet ANSI/ESD S20.20 standards and ISO 14644-1 Class 5 requirements for clean environments, guaranteeing reliable static control performance.

Measuring Your Workspace Dimensions

You'll need to start by measuring your workspace's length and width, marking any fixed elements like columns or wall fixtures that could affect ionizer placement.

For rectangular spaces, multiply the length by width to determine the total square footage that requires ionization coverage.

Standard office dimensions suggest a typical desk height of 730mm, which can help determine proper ionizer positioning. Don't forget to measure and note your ceiling height, as overhead ionizers must be mounted at specific heights to maintain effective coverage across your work area. Creating a rough layout sketch of your workspace can help you identify and track all areas requiring ionizer coverage.

Basic Layout Assessment

Before installing overhead ionizers, accurate workspace measurements form the foundation of proper coverage planning. Start by sketching a rough layout of your office space, marking distinct areas with clear identifiers.

You'll need to measure the length and width of quadrilateral spaces using a tape measure, beginning with the longest side. For triangular spaces, measure both the base and height to determine the area accurately. Following BOMA measurement standards, begin measurements from the inside surface of exterior walls. Implementing occupancy level analysis helps determine optimal ionizer placement for high-traffic areas.

When evaluating your layout, exclude non-occupiable spaces like restrooms and corridors, as these won't require ionizer coverage.

Consider fixed elements that might affect ionizer placement:

- Vertical penetrations like elevator shafts and stairwells

- Immovable structural elements such as columns and load-bearing walls

- Existing ceiling fixtures and mechanical systems

Factor in your furniture placement, particularly desk configurations, as they'll influence ionizer positioning.

Standard desk dimensions typically range from 120-180 cm in length and 60-90 cm in width, so verify you've accounted for these in your measurements.

Don't forget to add a buffer zone around furniture for accessibility and full functionality of both the workspace and ionizer coverage.

Room Height Considerations

While layout dimensions provide the foundation for ionizer coverage, proper ceiling height measurements are equally essential for ideal performance. You'll need to verify your ceiling height accommodates the minimum 12-24 inches of clearance above your work surface that most overhead ionizers require for effective operation. The dual fan system of the SCS 770112 ensures consistent ionization across the coverage area.

If you're working with standard 8-10 foot ceilings, you'll find most overhead ionizers are optimized for this range. However, if your workspace has higher ceilings, you might need to take into account more powerful units or strategic positioning to maintain adequate coverage. The installation of integrated lighting systems can improve visibility while maintaining proper ionization levels.

For lower ceilings, you'll want to adjust the mounting height and possibly the fan speeds to prevent over-ionization of your workspace.

Remember to factor in your specific workspace dimensions when measuring height. A two-fan ionizer typically covers a 2'x4' area, so you'll need to verify the mounting height allows for complete coverage of your work surface.

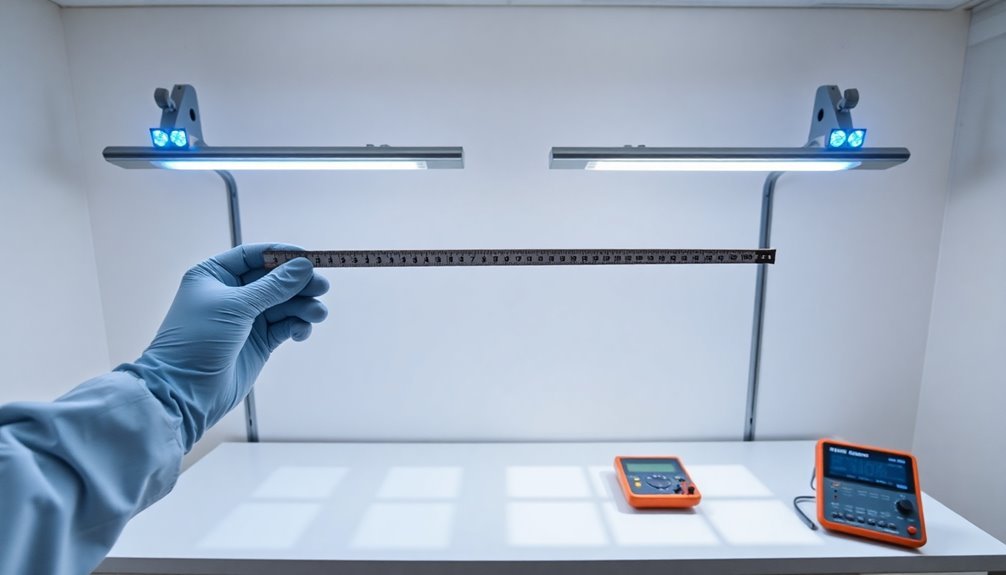

You can use hanging kits or shelf mounts for flexible installation options, but always verify performance with a charge plate monitor after installation. Regular testing and calibration will help maintain compliance with ANSI/ESD S20.20 standards and verify consistent protection for your workspace.

Optimal Mounting Height Calculations

Determining the ideal mounting height for overhead ionizers involves several essential calculations and considerations. For most installations, you'll want to position your ionizer approximately 18 inches above your work surface, though some models specify 24 inches for peak performance.

When calculating the mounting height, factor in the minimum clearance of 200mm if you're using a Feedback sensor system.

To guarantee proper coverage calculations, consider these environmental factors that will affect your ionizer's performance:

- Airflow patterns from HVAC systems can disrupt ion distribution, so measure and account for air currents in your workspace.

- Physical obstructions between the ionizer and work surface that might interfere with ion flow.

- Room height limitations that could force adjustments to standard mounting recommendations.

You'll need to validate your calculations through performance testing in actual operating conditions.

Remember that effectiveness diminishes outside recommended distances, so precise height positioning is vital.

When mounting your ionizer, make sure it's directly above your essential work area and properly grounded with less than 100 ohms resistance.

Use appropriate mounting hardware rated for the unit's weight, and verify that power cords don't create workplace hazards.

Fan Configuration Selection Guide

Building on proper mounting height, the next step in ionizer implementation is selecting the right fan configuration for your workspace.

You'll need to take into account the number of fans, coverage area, and speed options to guarantee peak performance for your specific application.

For standard workstations, choose between 2-3 fans that provide effective coverage ranging from 2×3 ft to 4×5 ft areas.

You'll want adjustable fan speeds to customize airflow based on your needs while maintaining noise levels around 66 dBA for a comfortable work environment.

If you're working with sensitive electronics, opt for precise airflow control and balanced ionization using either AC or DC technology.

For large workstations, select a 3-fan configuration to achieve wider coverage.

Your setup should include LED indicators for maintenance alerts and easy-access filters to minimize downtime.

When working in specialized industries like medical device manufacturing, you'll need configurations that meet ANSI/ESD S20.20 standards.

Think about units with integrated LED task lighting to enhance workspace visibility.

Remember to factor in power requirements – most units operate on 120 VAC, though some models offer different voltage options.

Choose configurations with automatic feedback systems to maintain peak performance and detect potential issues early.

Air Flow Pattern Analysis

An ionizer's air flow pattern plays an important role in achieving ideal static neutralization across your workspace. When you're setting up your overhead ionizer, you'll want to understand how the ionized air flows downward to effectively neutralize static charges.

The sealed plenum design guarantees that contamination doesn't enter your workstation while maintaining consistent ionization performance across different fan speeds.

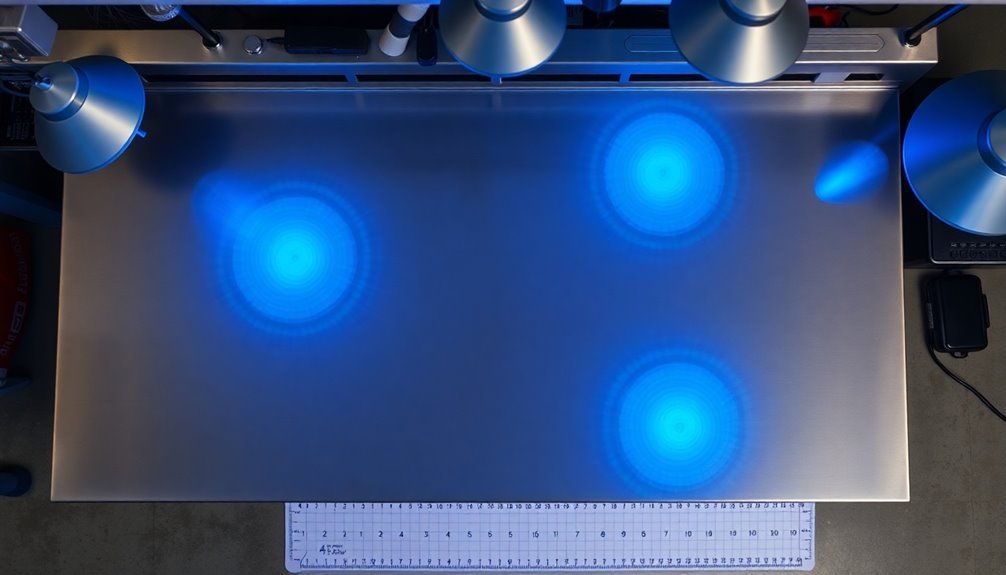

You'll achieve peak coverage by positioning the ionizer to deliver uniform air flow across your target area. The typical coverage spans 2' x 4' to 2' x 5', with discharge times of 3 seconds or less at 18 inches from the surface. The emitter points are strategically spaced to minimize ion recombination, maximizing the efficiency of your static control.

Key factors to monitor in your air flow pattern include:

- Fan speed settings that you can adjust based on your application needs

- Auto-feedback system performance to maintain proper ion balance

- Discharge time verification within your coverage area

The sealed plenum air flow design is particularly important if you're working in cleanroom environments or electronics assembly areas where contamination control is vital.

This feature helps you meet ANSI/ESD S20.20 standards while guaranteeing consistent ionization performance.

Multi-Unit Coverage Planning

Successful multi-unit coverage planning requires careful consideration of your workspace dimensions and ionizer specifications.

You'll need to determine the total area requiring coverage and select the appropriate number of units based on their individual coverage capabilities.

For rectangular workspaces, you can arrange units linearly using models like the SCS 770113 (2' x 5') or BFN803 (2' x 4'). If you're working with a larger area, plan for strategic overlap between units to guarantee extensive coverage and eliminate dead zones.

For example, two SCS 770113 units can provide effective coverage for a 4' x 5' workspace with proper overlap.

When planning your layout, you'll want to verify coverage using charge plate monitors and adjust unit placement accordingly.

Consider mounting height and orientation to optimize ion distribution.

For oddly shaped workspaces, you might need a combination of different models, such as the BFN802 (2' x 3') for smaller sections and the SCS 770113 for larger areas.

Don't forget to account for workspace obstacles and equipment that might affect ion flow when positioning your units.

Environmental Factors Affecting Coverage

Once you've established your ionizer layout, environmental conditions will greatly influence your coverage effectiveness.

Temperature and humidity levels play an important role in how well your ionizers perform, so you'll need to maintain stable conditions in your workspace. High humidity can greatly reduce your ionizer's effectiveness, while temperature fluctuations can disrupt the ion balance.

The presence of dust and particulates in your environment can seriously impact coverage performance.

You'll need to implement regular cleaning routines and consider adding air filtration to maintain ideal effectiveness. The physical layout of your workspace, including objects and surfaces, will affect how ions distribute throughout the area.

Here are key environmental factors you'll need to monitor:

- Temperature and humidity stability – maintain controlled levels to guarantee consistent ionizer performance

- Air quality management – implement filtration systems and regular cleaning schedules to reduce dust and particulate interference

- Workspace configuration – assess how furniture, equipment, and other objects might affect ion distribution patterns

Remember that environmental control isn't just about initial setup – you'll need to maintain these conditions consistently to guarantee your ionizers continue providing effective coverage.

Performance Verification Methods

You'll need to regularly verify your overhead ionizer's performance through standardized testing methods that comply with ANSI/ESD STM3.1.

To measure decay time effectively, use a Charged Plate Monitor (CPM) to test the ionizer's ability to neutralize charges from 1000V to 100V at specified distances.

Your maintenance and calibration schedule should include annual calibration of the ionizer, along with periodic verification checks every 6 months to guarantee consistent performance and compliance with the ±35V offset voltage requirement.

Testing Standards and Compliance

Overhead ionizer testing standards require strict adherence to ANSI/ESD S20.20 compliance within ESD protected areas. You'll need to verify your ionizer's performance according to ANSI/ESD STM3.1 and ESD TR53 protocols, guaranteeing discharge times stay under 3 seconds with offset voltages not exceeding ±35 volts. A charge plate monitor is vital for conducting these measurements at least annually.

When testing your overhead ionizer's compliance, you'll want to focus on these significant aspects:

- Performance verification of discharge times and offset voltage using calibrated test equipment

- Validation of automatic shutdown systems when supply voltage drops below specified levels

- Documentation of test results and maintaining calibration certificates for quality assurance

Your ionizer must demonstrate consistent performance within these parameters while operating in your specific environment.

For cleanroom applications, you'll need additional particle testing to meet ISO 14644-1 Class 4 standards. Regular testing helps maintain peak ionization performance and guarantees continued compliance with ESD standards.

Remember to keep detailed records of all verification tests and calibration certificates, as they're essential for maintaining your quality management system and demonstrating ongoing compliance.

Decay Time Measurement

Three essential measurements define effective ionizer performance verification: discharge time, offset voltage, and ion balance. You'll need to verify these metrics using a charge plate monitor (CPM) at the actual location where you'll protect your ESD-sensitive items.

When measuring decay time, you should position your CPM 18 inches from the ionizer – this is the standard testing distance where discharge times typically fall under 3 seconds. You'll need to measure both positive and negative decay times to guarantee proper ion balance, maintaining an offset voltage within ±10 volts for peak performance.

Your decay time measurements will vary based on several factors you must consider. The distance between your ionizer and charged objects, fan speed settings, and emitter type all affect discharge efficiency.

You'll also need to account for any physical obstacles that might disrupt ion flow and environmental conditions like temperature and humidity.

To maintain compliance, you should test your ionizers at least annually. If you're working with a large area, you might need multiple ionizers to achieve adequate coverage.

Always follow ANSI/ESD STM3.1 and ESD TR53 standards for accurate measurements.

Calibration and Maintenance Schedule

Regular calibration and maintenance form the backbone of reliable ionizer performance. You'll need to schedule annual calibration checks using a charge plate monitor to verify both positive and negative decay times, along with ion balance measurements.

Make certain you're documenting all calibration results for compliance and tracking purposes.

To maintain peak performance, establish a routine maintenance schedule that includes cleaning emitter points and checking safety mechanisms. When servicing your ionizers, you'll want to use integrated emitter point cleaners and make certain all maintenance is performed without contaminating your workspace.

Key performance verification requirements include:

- Testing discharge times to confirm they're under specified limits (typically <3 seconds)

- Measuring offset voltage to verify it stays within ±10 volts

- Conducting coverage area tests according to your specific model requirements

Don't forget to keep your calibration tools ready and properly maintained. You'll need charge plate monitors, emitter point cleaners, and appropriate safety equipment.

Follow ANSI/ESD S20.20 and ESD TR53 standards during all verification procedures, and make certain your ionizer performs consistently across all speed settings.

Remember to retain calibration certificates for each ionizer in your facility.

Frequently Asked Questions

How Often Should Emitter Points Be Cleaned to Maintain Optimal Coverage?

You'll need to clean your ionizer's emitter points every 1-2 months in high-use environments. Don't skip this maintenance, as dirty points can reduce performance and cause ion imbalance in your system.

Can Overhead Ionizers Interfere With Sensitive Electronic Test Equipment Nearby?

Yes, your overhead ionizers can interfere with sensitive electronics through RFI and EMI if they're not properly certified. To minimize risks, you'll want units with FCC Part 15 Class B certification and balanced ion output.

What's the Typical Power Consumption Difference Between Two-Fan Versus Four-Fan Models?

You'll typically find that four-fan ionizers consume 10-20 watts more power than two-fan models. While two-fan units use 10-40 watts, four-fan versions generally need 20-60 watts to operate effectively.

Do Overhead Ionizers Require Special Voltage Requirements for International Installations?

Yes, you'll need to contemplate international voltage standards. While North American ionizers typically use 120 VAC, you'll need 230 VAC models for European installations or units with universal power supplies for global compatibility.

How Does Humidity Affect the Ionizer's Coverage Area and Performance?

Your ionizer's coverage area expands in high humidity as ions travel further, but shrinks in low humidity. You'll notice better performance above 45% humidity and reduced effectiveness below 30% humidity.

In Summary

You've now got the tools to properly calculate and implement overhead ionizer coverage for your workspace. Remember to account for your specific dimensions, environmental conditions, and airflow patterns when planning your setup. Don't forget to verify coverage using charge plate monitors and make adjustments as needed. Regular maintenance and monitoring will guarantee your ionization system continues performing at its best.

Leave a Reply