To verify your personnel ground tester, you'll need to follow three essential steps. First, connect your tester properly to the facility's grounding electrode system using a minimum 14 AWG equipment grounding conductor. Next, mount the tester at an accessible height and guarantee it's positioned on a clean, level surface for consistent testing of both wrist straps and footwear. Finally, perform operational checks to confirm the tester's functionality before starting daily operations, including verifying proper resistance measurements and indicator lights. Understanding these fundamentals will help you establish a reliable ESD testing protocol.

Daily Testing Requirements

To maintain effective ESD control, you'll need to test both wrist straps and footwear daily before handling any static-sensitive devices.

When testing your wrist strap, wear it during the verification process to check the complete system, including the band, ground cord, and skin contact. You'll need to measure the resistance to ground and verify it meets specifications according to ANSI/ESD S1.1 standards. Visual inspection alone is not enough as hidden failures can occur in grounding equipment.

For footwear testing, you must check each foot separately while wearing the foot grounders. Place them on your shoes following manufacturer guidelines and test each foot individually on the floor plate.

If you receive a fail result, stop work immediately and troubleshoot the issue by examining both the foot grounder and contact strip.

You'll need to document all test results for quality control. Record your identification, test measurements, and resistance readings.

Don't handle any ESD-sensitive components until you've confirmed proper grounding through successful tests. Remember, these daily checks prevent static damage and verify you're maintaining compliance with ESD standards.

If either your wrist strap or footwear fails testing, resolve the issue before continuing your work.

Equipment Setup and Verification

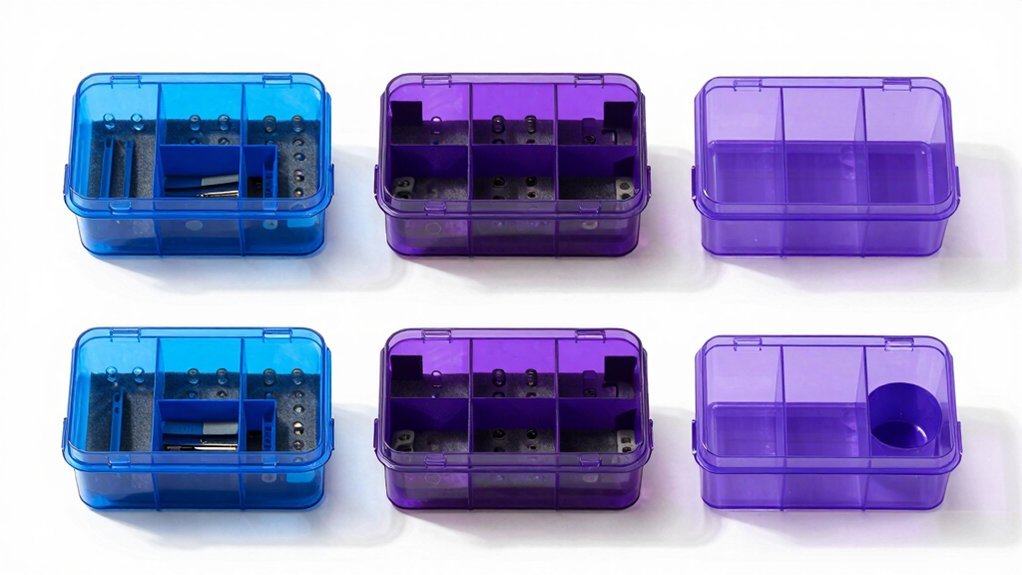

A reliable ESD testing station begins with proper equipment selection and setup. You'll need to choose between wrist strap testers, combined testers, or models with split footplates depending on your facility's requirements. Consider testers with data logging capabilities if you need to maintain detailed compliance records.

Once you've selected your equipment, proper installation is vital for accurate testing. Connect your tester to the facility's grounding electrode system using a minimum 14 AWG equipment grounding conductor. Regular visual inspections of grounds are essential to maintain system integrity.

Before daily operations begin, verify your tester's functionality through operational checks.

For top-notch testing station performance, follow these essential setup steps:

- Mount the tester at a comfortable height where operators can easily access both wrist strap and footwear testing components.

- Install the footplate on a clean, level surface to guarantee consistent contact during testing.

- Verify that all grounding connections are secure and free from corrosion or damage.

- Test the alarm systems and indicators to confirm they're working properly.

Remember to position your tester in a location that won't impede workflow while remaining easily accessible for your daily verification procedures.

If you're using a combined tester, make sure there's adequate space for operators to perform both wrist strap and footwear tests comfortably.

Record Keeping and Compliance

Since proper documentation forms the backbone of ESD compliance, maintaining accurate records of personnel ground testing is essential for meeting industry standards. You'll need to verify daily testing records of wrist straps and footwear, with each entry including operator identification and specific resistance measurements. For wrist straps, measurements must show less than 3.5 x 10^7 ohms for safe operation.

You can streamline your record-keeping process by implementing digital systems that automatically log test results into a database. These systems offer web-based access and can generate customized reports that demonstrate compliance with ANSI/ESD S20.20 and IEC 61340-5-1 standards.

You'll benefit from automated alerts that notify you of failed tests or concerning patterns in test results.

Your record-keeping system should support quality control initiatives by tracking both short-term and long-term corrective actions. When you implement automated systems, you'll reduce costs associated with manual logging while enhancing operator accountability.

Make sure your system can restrict access to ESD Protected Areas based on test results and maintain detailed records for compliance verification. If you're operating globally, choose a system that offers multilingual support to accommodate international teams.

Frequently Asked Questions

How Often Should Personnel Ground Testers Themselves Be Calibrated?

You should calibrate your personnel ground testers annually, with verification checks every 6-12 months. If you're handling critical ESD-sensitive items, you'll need to adjust the frequency based on risk assessment.

Can Multiple Wrist Straps Be Tested Simultaneously on the Same Tester?

No, you can't test multiple wrist straps simultaneously on the same tester. You'll need to test each wrist strap individually, as testers are designed to evaluate one wrist strap and footwear pair at a time.

What Happens if Someone Fails Testing While Wearing Different Shoe Brands?

If you're failing tests with different shoe brands, you'll need to check each shoe individually, replace non-compliant footwear, and verify you're using ESD-approved shoes that meet grounding standards for proper protection.

Are Wireless Personnel Ground Testers as Reliable as Wired Ones?

While your wireless ground testers can be reliable, they're not quite as dependable as wired systems. You'll get more consistent readings with wired testers due to their direct physical connection and simpler design.

Do Temperature and Humidity Affect Personnel Ground Tester Accuracy?

Yes, your personnel ground tester's accuracy is affected by both temperature and humidity. You'll need proper calibration as temperature changes impact humidity levels, which can skew readings if you don't account for environmental conditions.

In Summary

Your daily verification of personnel ground testers is critical for workplace safety and compliance. By following these three key steps – performing required daily tests, properly setting up and verifying equipment, and maintaining accurate records – you'll guarantee reliable static control and meet industry standards. Don't skip these essential procedures, as they protect both workers and sensitive equipment from dangerous static discharge.

Leave a Reply