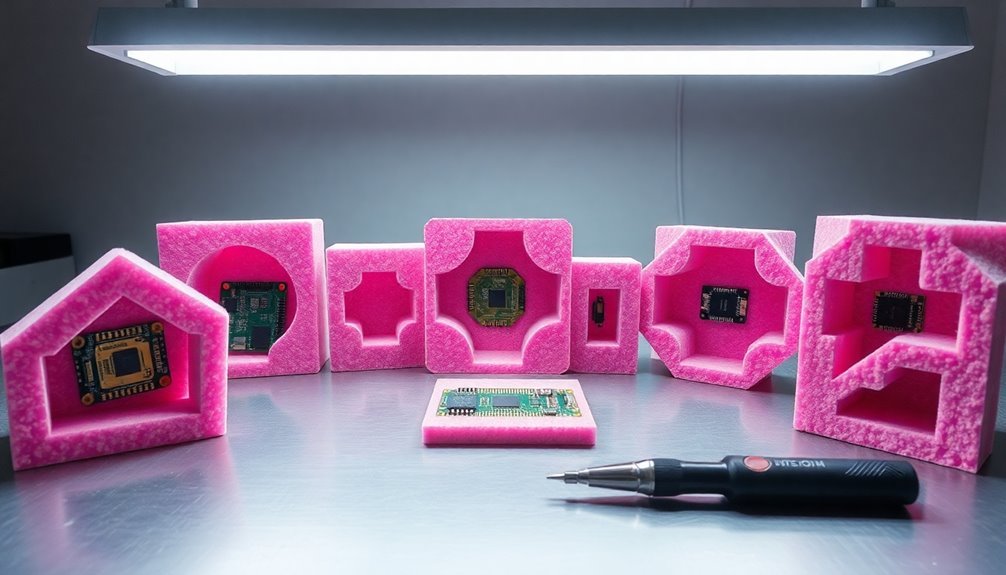

You'll need to handle pink anti-static foam sheets carefully to protect sensitive electronics from static discharge and physical damage. Choose the right thickness based on your component's weight and fragility, typically between 1/8" to 1" thick. Cut the foam using sharp utility knives or hot wire cutters for precise fits, and always work on a clean surface while wearing protective gear. Store components by gently inserting them into custom-cut foam cavities, making sure leads aren't bent or damaged. Keep your packed electronics in a clean, dry environment, as proper storage extends the foam's protective properties. There's much more to maximizing this versatile packaging material's effectiveness.

Understanding Pink Anti-Static Foam Properties

Three key properties make pink anti-static foam essential for electronics protection.

First, its anti-static capability allows it to dissipate electrical charges within 0.05 seconds, preventing harmful static buildup that could damage sensitive components. With a surface resistance of 10^5 to 10^11 ohms, you'll find this foam effectively protects circuit boards, computer chips, and other electronic devices from static discharge. The material's thermoformable properties make it adaptable for complex shapes and configurations.

Second, you're getting excellent physical protection thanks to the closed-cell polyethylene construction. The foam comes in various thicknesses from 1/8" to 1" and densities of 1.7 lb and 2 lb, providing customizable cushioning that's both shockproof and waterproof.

You can easily cut, split, and shape it to fit your specific needs.

Third, the foam's pink color isn't just aesthetic – it helps you quickly identify it as ESD-safe material in your workspace. The material is non-corrosive and non-toxic, making it safe for handling sensitive electronics.

While it's not meant for long-term storage due to decreasing effectiveness over time, its thermal stability remains consistent with less than 2% variation, ensuring reliable protection during its service life.

Choosing the Right Foam Type

Several key factors determine whether pink or black foam is the right choice for your electronics protection needs. Your decision should primarily depend on the duration of use and the level of protection required for your specific electronic components.

If you're looking for short-term protection, pink foam sheets are your most cost-effective option. They'll provide excellent physical shock protection during handling, packaging, and shipping. The foam's closed cell construction makes it exceptionally waterproof and moisture-resistant. However, you'll need to take into account that pink foam's anti-static properties diminish after about six months, making it unsuitable for long-term storage solutions.

For long-term applications, you'll want to invest in black foam. While it's more expensive, it maintains its electrical properties indefinitely and won't discolor over time. Black foam's surface resistivity of 1 x 10^3 to 1 x 10^9 ohms offers permanent ESD protection that's essential for sensitive electronics.

You should also think about customization needs. Both foam types can be die-cut and laminated into various configurations like sheets, trays, and inserts.

Remember to verify that your chosen foam meets ANSI/ESD STM11.11 standards and provides the appropriate level of cushioning for your specific electronic components.

Safety Guidelines for Handling

Now that you've selected the appropriate foam type, proper handling procedures must be followed to maintain its protective properties. You'll need to regularly inspect the foam for signs of degradation and verify its ESD compliance with ANSI/ESD standards. Remember that pink foam has a limited shelf life, so it's essential to monitor its effectiveness over time. Regular audits and testing are necessary to maintain reliable ESD protection performance.

To prevent damage to sensitive components, you'll want to minimize direct contact between the foam and electronics, as all foam materials can generate FOD through particle shedding. Store your foam sheets in a controlled environment to maximize their lifespan and maintain their ESD properties.

| Safety Aspect | Required Action | Frequency |

|---|---|---|

| ESD Testing | Verify compliance with ANSI/ESD S20.20 | Monthly |

| FOD Control | Inspect for particle shedding | Weekly |

| Quality Check | Test ESD protective properties | Quarterly |

When working in EPA environments, you must guarantee your foam meets all compliance requirements. If you're handling components sensitive to less than 100 volts human body model, consider implementing additional protective measures. For long-term storage solutions, you'll want to explore alternative materials, as pink foam is best suited for short-term applications.

Common Packaging Applications

Pink foam packaging solutions offer diverse applications across electronics manufacturing and handling environments. You'll find these materials particularly useful for protecting ESD-sensitive devices during handling, shipping, and storage operations.

When you're packaging circuit boards, IC components, or sensitive electronic assemblies, you can use the foam as a protective liner or cushioning material. The material's surface resistance range of 10^5-10^11 ensures reliable static discharge protection.

You can customize the foam sheets to fit your specific needs by cutting, die-cutting, or laminating them to match your product dimensions. For storing electronic components, you'll want to use the foam for lining ESD boxes or creating specialized compartments.

It's especially effective for telecommunications equipment, medical devices, and handheld electronics that require both physical and electrostatic protection.

When you're working with displays or LED lighting solutions, you can use pink foam as blocking and bracing material to prevent movement during transit. The closed-cell structure provides excellent cushioning against shock and vibration while maintaining its anti-static properties.

For IC leads and PIN insertion applications, you'll find the high-density versions particularly suitable, as they offer precise component positioning while maintaining ESD protection.

Cutting and Customization Techniques

You'll need a hot wire cutter or utility knife as your primary tools when working with pink foam sheets for electronics packaging.

For custom-fit cuts, you can use a straightedge guide with your cutting tool to achieve precise straight lines, or opt for a hot wire cutter when creating curved shapes and cavities. Double-check measurements before making any cuts since foam sheets cannot be reattached if cut incorrectly.

The key to successful customization lies in controlling your cutting speed and maintaining consistent pressure, ensuring clean edges that perfectly match your electronic components' dimensions.

Basic Tool Requirements

Proper tool selection stands at the heart of working effectively with pink foam sheets. You'll need a variety of cutting tools to achieve different results, with utility knives and razor blades being your primary instruments for straight lines and shallow cuts.

When working with curved or complex shapes, you can opt for a hot wire cutter, though you shouldn't use this method on polyurethane foam.

For precise, detailed work, you'll want to think about using a laser cutter, but keep in mind this requires specialized equipment.

Whatever cutting tool you choose, make certain your blades are sharp to prevent tearing or crushing the foam material. You'll also need metal straightedges or rulers to guide your cuts and maintain accuracy.

To protect yourself while working, you'll need basic safety equipment including gloves and safety glasses. Remember to keep your work surface clean and clear of debris to make certain smooth, accurate cuts.

When making cuts, apply gentle but consistent pressure – too much force can cause tearing or make your blade veer off course, compromising the precision of your work. The foam's closed cell structure makes it especially suitable for creating custom-fit protective packaging.

Custom Fit Cutting Methods

With your tools ready, it's time to explore specific techniques for achieving precise custom fits in your foam projects.

Hot wire cutting offers excellent precision when you're working with larger sheets, allowing you to create clean, smooth edges with minimal debris. When using a hot wire cutter, ensure you have proper ventilation and exhaust to avoid inhaling potentially harmful fumes.

For intricate designs, you'll find precision cutting machinery particularly effective at achieving exact dimensions needed for electronics packaging.

If you're working on smaller projects, you can use a utility knife to carefully cut the pink anti-static foam. Make sure to measure twice and cut once, following your marked guidelines closely.

For complex shapes, consider thermoforming the foam to create custom-fitted cavities that perfectly match your electronics components.

When you need thicker protection, you can laminate multiple foam sheets together. This technique's particularly useful when you're creating deep compartments for delicate equipment.

For professional-grade results, you might want to explore custom cutting services, especially for bulk orders or particularly challenging designs.

Remember that whatever method you choose, the foam's anti-static properties will remain intact, continuing to protect your electronics from harmful static charges during storage and transport.

Storage and Environmental Considerations

Safe storage of electronic components demands careful consideration of environmental factors, and pink foam sheets offer several advantages in this area. The closed-cell structure provides excellent resistance against moisture, bacteria, and mildew, making it ideal for protecting your sensitive electronics in various environments. The foam's non-corrosive properties make it exceptionally safe for long-term contact with electronic components.

| Storage Feature | Benefit |

|---|---|

| Anti-static Properties | Protects against electrostatic discharge |

| Water Resistance | Prevents moisture damage in humid conditions |

| Chemical Stability | Resists grease and harmful chemicals |

You'll find that pink foam maintains its protective properties across different temperature ranges, and you don't need to worry about particle contamination since it's non-sloughing. When storing your electronics, remember that while the foam's anti-static properties are effective, they're not designed for long-term storage solutions.

To maximize the foam's protective capabilities, store your components in a clean, dry environment. Don't attempt to clean the foam with harsh chemicals, as this can compromise its integrity. If you're planning outdoor storage, consider adding foil or cardboard encasement for enhanced UV protection. The foam's available custom configurations allow you to create the perfect storage solution for your specific electronic components.

Combining With Other Protective Materials

Pink foam sheets work best when you layer them strategically with other protective materials like bubble wrap for maximum shock absorption.

You'll get the best protection by wrapping your electronic components first in pink foam, then placing them in anti-static bags to create a dual barrier against static and physical damage.

Adding foam corner protectors to this combination provides extra safeguarding at the most vulnerable points of your electronic equipment.

Layer With Bubble Wrap

Through smart layering, combining pink foam sheets with bubble wrap creates a superior protective solution for electronics. You'll get enhanced protection by utilizing the shock-absorbing properties of bubble wrap alongside the non-abrasive, anti-static benefits of pink foam sheets.

This combination is particularly effective for sensitive electronic components that need multiple layers of protection.

When layering these materials, start by cutting the pink foam sheets to precisely fit your electronic components. Place the foam directly against the electronics to take advantage of its non-abrasive and anti-static properties.

Then, wrap bubble wrap over the foam layer to add shock absorption and impact resistance. Make sure you're using anti-static bubble wrap to maintain the static-free environment your electronics require.

You can customize this layering technique based on your specific needs. For irregularly shaped items, use the pink foam as a base layer for blocking and bracing, then apply bubble wrap for additional cushioning.

In high-impact scenarios, consider adding extra layers of bubble wrap. Remember to seal your packages securely to prevent movement during transport, ensuring both layers work together effectively.

Anti-Static Bag Combinations

While bubble wrap provides excellent cushioning, combining anti-static bags with pink foam sheets creates an even more thorough protection system for sensitive electronics. You'll get dual protection: physical shock absorption from the foam and electrostatic discharge protection from the bags.

When you're combining these materials, you'll need to choose the right type of anti-static bag for your needs. Pink anti-static polyethylene bags work well for basic static dissipation, while Faraday Cage effect bags offer additional protection against electromagnetic interference.

For moisture-sensitive components, consider using moisture barrier bags with your foam sheets.

You can customize this combination to fit your specific requirements. Cut the foam sheets to match your electronic components' dimensions, then select anti-static bags that accommodate both the foam and the item. Make sure the materials you're using are compatible and meet ESD standards for your application.

To maximize cost-effectiveness, evaluate whether you need additional features like humidity control or specialized die-cut inserts. You can also incorporate pre-cut foam options for quicker packaging solutions.

Remember to assess your electronics' specific protection needs before selecting your final combination of materials.

Foam Corner Protection

Combining foam corner protection with complementary materials creates a robust defense system for your electronics. When you're using pink foam sheets, you'll want to integrate them with cardboard inserts for enhanced structural support.

You can also add bubble wrap or paper fill between the foam corners to guarantee complete protection against impacts and vibrations.

For maximum protection, select closed-cell polyethylene foam corners, as they'll provide excellent moisture resistance and durability. If you're dealing with particularly sensitive electronics, consider using dense polyurethane foam for high-impact protection.

You'll want to secure these foam corners using appropriate adhesives – Foam-Lock or specifically designed foam adhesives work best for safe, non-toxic bonding.

When assembling your protection system, guarantee you're combining the foam corners with durable outer packaging. For custom-shaped electronics, you can design specific foam corner protectors that fit your exact needs.

Remember to clamp or weigh down any glued foam components during the adhesive curing process to guarantee secure attachment. This multi-layered approach using foam corners and complementary materials will substantially reduce the risk of damage during transport or storage.

Best Practices for Electronics Protection

Proper protection of electronics requires careful consideration of pink foam's specific properties and application methods. You'll want to select either polyethylene foam for moisture-sensitive components or polyurethane foam for items needing extra cushioning.

Choose the appropriate thickness based on your component's weight and fragility, typically ranging from 1/8" to 1" thick.

When handling electronic components, make certain you're using the foam for short-term static protection, as its anti-static properties aren't permanent. Insert IC leads carefully into the foam, and avoid repeatedly inserting them in the same spot.

You'll get the best results by customizing the foam to your specific needs – cut it precisely to size and consider using adhesive backing for secure placement.

For maximum protection, implement these key practices: use closed-cell foam when moisture resistance is vital, guarantee proper thickness for adequate cushioning, and verify that your foam meets the required surface resistance range of 10e5-10e11 ohms.

If you're packaging items for shipping, combine pink foam with appropriate blocking and bracing techniques. Remember to check that the foam you're using complies with RoHS and REACH regulations for electronic component protection.

Frequently Asked Questions

Can Pink Anti-Static Foam Be Reused Multiple Times for Shipping Electronics?

You shouldn't reuse pink anti-static foam multiple times, as it loses its ESD protection after about 6 months. For repeated shipping needs, you'll want to take into account permanent anti-static EVA or PE foam alternatives.

Does the Foam's Pink Color Fade Affect Its Anti-Static Protection Properties?

No, you don't need to worry about color fading. The pink shade doesn't affect the foam's anti-static properties, as these come from its chemical composition with surfactants, not from the color itself.

How Long Does Pink Foam Maintain Its Anti-Static Properties in Sealed Packaging?

You'll typically get 1-2 years of reliable anti-static protection from sealed pink foam, though it's best to check with your supplier. Storage conditions like temperature and humidity can affect its protective lifespan.

Are There Specific Cleaning Methods for Contaminated Pink Anti-Static Foam?

You can't effectively clean contaminated pink anti-static foam. Once it's decomposed, you'll need to dispose of it properly and replace it. Focus on cleaning the electronics it has contaminated using IPA solutions instead.

Can Pink Foam Sheets Be Safely Used With Batteries and Charging Devices?

You shouldn't rely on pink foam sheets for battery protection. While they're anti-static, they can't withstand battery fires. For charging devices, they provide good cushioning but consider fiberglass or mineral cloths for fire safety.

In Summary

Pink anti-static foam sheets are your first line of defense for protecting sensitive electronic components. Make sure you're selecting the right density and thickness for your specific needs, and always handle the foam with clean, dry hands. When you combine proper cutting techniques, careful storage practices, and appropriate layering with other protective materials, you'll create a safe environment that shields your electronics from both physical damage and static discharge.

Leave a Reply