Pink anti-static foam provides your sensitive electronics with seven essential layers of protection. You'll get reliable static discharge prevention with resistance ratings of 10^6 to 10^11 ohms, while the multi-layered shock absorption system guards against physical impacts. The closed-cell structure keeps out moisture and contaminants, and the material's chemical resistance shields against corrosive factors. You can easily customize it to fit specific components, and it's fully recyclable for environmental sustainability. The foam maintains its protective qualities across varying temperatures and humidity levels. Discover how these features work together to deliver complete protection for your valuable electronic components.

Static Discharge Protection in Action

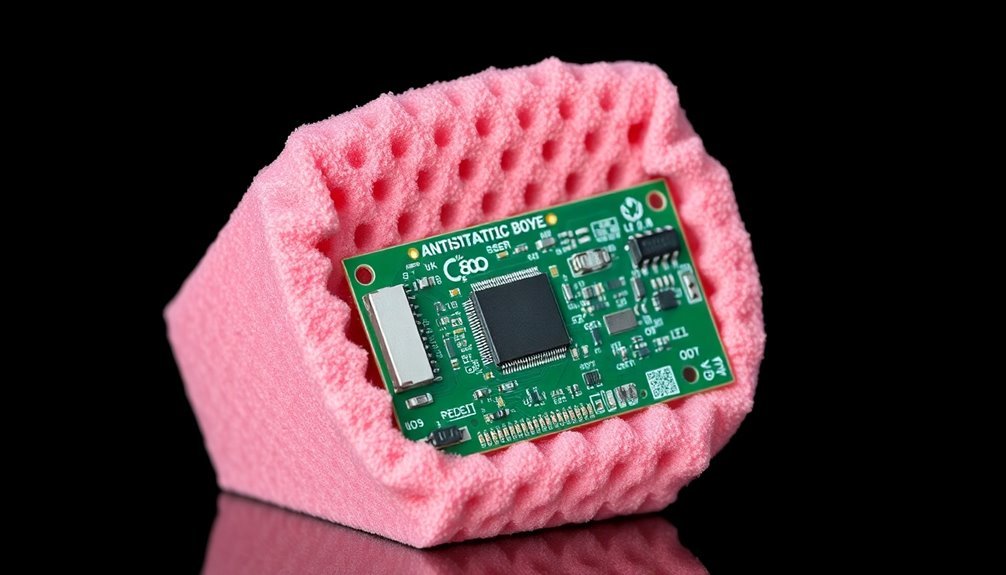

When handling sensitive electronics, pink anti-static foam serves as your first line of defense against damaging static discharge. This specially designed material combines anti-static polyethylene foam with protective agents and a distinctive pink dye that helps you identify it quickly. The shockproof and waterproof nature of the foam provides exceptional protection during shipping and handling.

The foam's impressive surface and volume resistance ratings of 10^5 to 10^11 ohms guarantee your components stay protected from harmful static charges.

You can count on the foam's rapid charge decay time of less than 0.05 seconds to neutralize static threats quickly. Its closed cell structure keeps moisture and contaminants away from your sensitive parts while allowing you to shape it precisely around your components.

When you're working with circuit boards or other ESD-sensitive devices, the foam's non-corrosive properties guarantee your equipment remains undamaged during storage and transport.

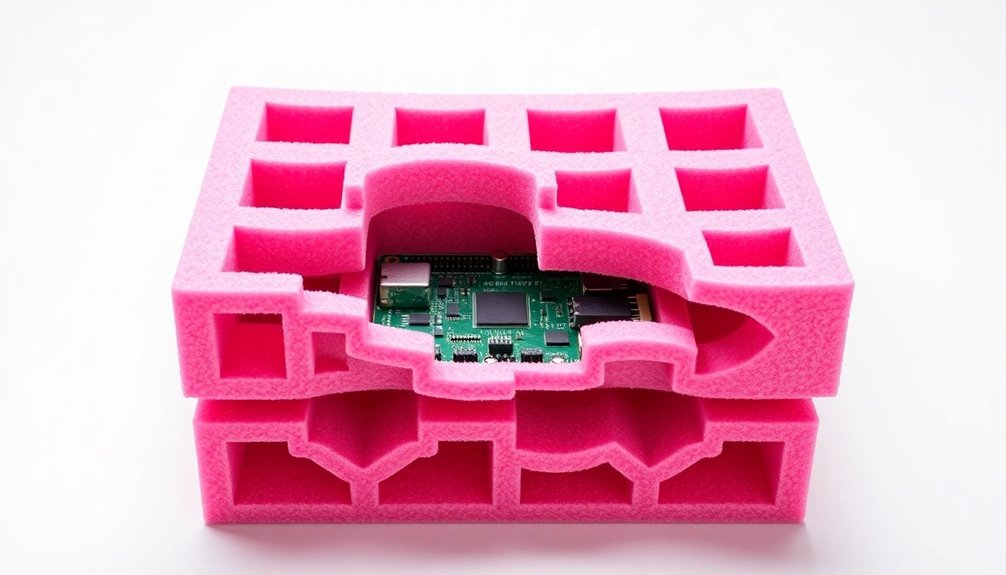

You'll need to remember that this protection isn't permanent – the foam works best as a short-term solution and requires regular testing to maintain its effectiveness. For maximum protection, you can customize the foam by cutting, splitting, or laminating it to create the perfect fit for your specific electronic components.

Superior Cushioning Against Physical Impact

Your pink foam packaging creates a multi-layered shock absorption system that actively disperses impact forces away from your sensitive electronics.

When your device encounters sudden physical stress, the foam's egg-crate design works to distribute the force across its surface area, preventing concentrated pressure points that could damage components. The polyurethane foam material provides exceptional flexibility and softness for optimal cushioning performance.

You'll find this cushioning mechanism particularly effective during shipping and handling, as the foam's ability to mold around your electronics guarantees consistent protection from all angles.

Shock-Absorbing Layer System

Today's sensitive electronics demand superior protection against physical impacts, and shock-absorbing layer systems provide exactly that through their multi-material construction.

Modern shock-absorbing systems utilize various materials like viscoelastic polymers and polyurethane compounds, each playing a crucial role in safeguarding your devices. These materials effectively convert kinetic energy into heat that safely dissipates into the atmosphere.

The layered construction approach means you're getting multiple levels of protection, with each material offering unique benefits for your electronics:

- Viscoelastic polymers provide flexibility and superior energy absorption

- Polyurethane potting compounds offer excellent thermal stability from -30°C to 70°C

- EPP/EPS foams deliver waterproofing and chemical resistance

- Multi-material combinations enhance overall shock absorption capabilities

You can count on these systems to protect your electronics through their customizable geometry and thickness. The materials work together to create an ideal damping ratio, effectively absorbing and dissipating impact energy.

When you're looking for thorough protection, you'll appreciate how polyurethane compounds can encapsulate components while providing both electrical insulation and mechanical protection. The system's adaptability means you're getting protection that's specifically tailored to your electronic devices' needs.

Impact Force Distribution Mechanics

Understanding the mechanics behind impact force distribution helps you protect sensitive electronics through superior cushioning design. When an impact occurs, the force is calculated as the ratio of momentum change to collision time (F = Δp/Δt). The high magnitude force generated during sudden collisions makes protective cushioning critical for electronics.

Pink foam's structure works by extending this collision time, substantially reducing the peak force your electronics experience.

You'll find that pink foam's effectiveness stems from its ability to optimize deformation distance, a vital factor in the average impact force equation (F_avg = 1/2 m v^2 / s). As your device experiences a shock, the foam's cellular structure progressively compresses, converting the harmful kinetic energy into work done during deformation. This process mirrors the principle behind automotive crumple zones but on a smaller scale.

The foam's material properties enable it to distribute Hertzian contact stresses across a wider area, preventing concentrated force points that could damage your electronics.

When your device falls, the foam calculates the impact force (F_avg = m a_g h / s) and responds by deforming systematically. This controlled deformation increases the collision time period, ensuring your sensitive components receive only a fraction of the original impact force.

Long-Term Storage Safety Features

Your electronics stay secure during extended storage thanks to pink foam's closed-cell structure, which provides steady protection against temperature changes and humidity variations.

The foam's chemical resistance properties help preserve delicate components from corrosive environmental factors during storage.

While the foam won't actively control moisture levels like poly bags, its inert composition creates an effective barrier that keeps dust and other contaminants away from sensitive components.

The foam's durable construction maintains these protective qualities over time, making it an excellent choice for both short-term transport and long-term warehousing of electronic items.

Humidity Control Properties

Over extended storage periods, pink anti-static foam displays substantial limitations in humidity control, which can compromise its protective capabilities for sensitive electronics. Unlike specialized materials with moisture barriers, pink foam doesn't inherently regulate humidity levels, making it susceptible to environmental fluctuations that can impact its anti-static performance. Pink poly bags provide superior moisture regulation compared to foam packaging.

You'll need to be aware of these critical humidity-related concerns when using pink foam:

- The foam's anti-static properties can degrade markedly in environments with unstable humidity, leading to increased risk of ESD damage.

- Without built-in moisture control, the surface resistance of the foam rises over time, reducing its effectiveness in preventing static charge buildup.

- The material's performance is heavily dependent on environmental conditions, making it less reliable for long-term storage compared to alternatives like pink poly bags.

- You'll need to implement regular inspection and replacement protocols to maintain adequate protection levels.

For the best protection of your sensitive electronics, you should consider supplementing pink foam with dedicated humidity control measures or choosing alternative materials specifically designed for moisture management. This becomes particularly vital in environments where humidity levels fluctuate frequently or in cases requiring extended storage periods.

Temperature Fluctuation Protection

During extended storage periods, pink anti-static foam provides vital thermal insulation that shields sensitive electronics from temperature fluctuations. The foam's closed-cell structure creates a stable internal environment, protecting your devices from external temperature changes that could potentially cause damage during transportation and storage. The material's surface resistance range between 10^6 to 10^11 ohms ensures consistent protection against static discharge.

You'll find that pink foam maintains its cushioning properties across various temperature ranges, making it particularly effective for long-term storage solutions. However, it's critical to monitor the foam's shelf life, as its protective capabilities, including ESD protection, can diminish over time.

When you're storing electronics for extended periods, you'll need to verify that the foam complies with ANSI/ESD standards. The foam's anti-static properties continue to dissipate static charges effectively across different temperatures within its designated shelf life. This feature is especially important because regular non-ESD foam doesn't offer reliable thermal insulation for sensitive components.

To maximize protection, you should consider the foam's durability and its ability to withstand temperature variations when planning long-term storage. Remember that while the foam's structure contributes to thermal stability, its effectiveness depends on proper maintenance and timely replacement before its ESD properties deteriorate.

Dust-Free Component Preservation

Beyond temperature control, maintaining a dust-free environment stands as a primary concern for electronic component preservation. You'll find that pink anti-static foam plays a vital role in protecting your sensitive electronics from both dust and static damage. This specialized polyethylene foam, with its resistance of less than 10^11 ohms, effectively dissipates electrostatic charges while creating a protective barrier against contaminants. Dust particles can cause serious damage as they contain organic and mineral materials that compromise component reliability.

When storing your electronic components, you'll want to focus on these essential protective measures:

- Use original packaging with built-in supports, complemented by pink anti-static foam inserts for maximum protection.

- Clean your devices thoroughly before storage and seal all gaps with appropriate tapes.

- Store components in antistatic bags within the foam-protected environment.

- Maintain a dry, cool storage area to prevent moisture-related complications.

The foam's closed-cell structure and non-corrosive properties make it ideal for short-term protection, though you'll need to think about alternatives for long-term storage due to potential degradation of its electrical properties.

The material's customizable nature allows you to create precise fits for your specific components, ensuring thorough protection against dust and physical damage during handling and storage.

Customizable Shapes and Sizes

Pink foam's shape-shifting capabilities make it an invaluable packaging solution for electronics manufacturers. You'll find that this versatile material can be precisely cut into any shape using CNC routers, ensuring your electronic components fit snugly and stay protected during transit.

Whether you're packaging oddly-shaped circuit boards or uniquely designed devices, you can customize the foam to match your exact specifications.

You can select from various thicknesses and sizes to achieve superior protection for your electronics. The foam's density of 2 lbs/ft³ provides effective cushioning, and you can even laminate multiple layers when you need extra protection. While it's softer and lighter than black PE foam, it still delivers reliable protection for medium to heavy items.

You'll appreciate how this material's anti-static properties safeguard sensitive components while its adaptable nature suits diverse applications. From delicate medical devices to robust communication equipment, you can tailor the foam to create custom-fit compartments.

This precision cutting minimizes material waste while maximizing protection, making it an efficient choice for your high-grade packaging needs.

Environmental Impact and Sustainability

Environmental consciousness in electronics packaging brings important considerations when using pink anti-static foam. You'll need to be aware that this foam degrades over time, losing its protective anti-static properties and potentially creating risks for your sensitive components. When the foam expires, it can actually generate static electricity instead of preventing it, making proper disposal essential for environmental safety.

To maintain sustainability while protecting your electronics, consider these key practices:

- Check your foam's ESD compliance regularly through verification testing to confirm it's still providing adequate protection.

- Replace degraded foam with EPEAT-registered alternatives that meet environmental performance standards.

- Explore eco-friendly packaging materials that offer similar protection while reducing environmental impact.

- Implement proper disposal methods for used foam through electronics recycling programs.

You can contribute to sustainable electronics practices by choosing recyclable packaging options and energy-efficient storage solutions. NSF-supported research continues to develop more environmentally friendly alternatives to traditional pink foam, focusing on biodegradable materials and safer chemical processes.

When you're handling electronic components, remember that sustainable choices in packaging materials directly impact both component protection and environmental preservation.

Temperature and Humidity Resistance

Three critical factors determine the effectiveness of anti-static foam: temperature stability, humidity resistance, and environmental durability. When you're protecting sensitive electronics, you'll find that pink anti-static foam maintains consistent performance across varying temperatures without significant impedance changes.

| Feature | Benefit |

|---|---|

| Temperature Stability | Maintains anti-static properties in hot and cold conditions |

| Humidity Resistance | Low water absorption prevents performance degradation |

| Shock Protection | Cushions electronics against physical damage |

| Long-term Effectiveness | Maintains properties for up to six months |

You won't need to worry about moisture damage, as the polyethylene-based foam resists water absorption and maintains stable surface impedance even in humid conditions. The foam's specialized anti-static coatings guarantee reliable performance for up to six months, giving you extended protection for your valuable equipment.

What's particularly impressive is the foam's ability to maintain its protective properties while providing vital shock absorption. You'll get thorough protection against both physical damage and static discharge, making it an ideal solution for shipping and storing sensitive electronic components. The non-sloughing nature of the foam guarantees your electronics stay clean and contamination-free throughout their storage period.

Cost-Effective Component Protection

From a cost perspective, pink anti-static foam delivers exceptional value for protecting electronic components. You'll find it's substantially more economical than alternative ESD materials, while still providing thorough protection for your sensitive electronics.

The foam's versatile design allows you to customize it precisely to your needs, minimizing waste and maximizing cost efficiency.

When you're looking to optimize your component protection budget, pink foam offers these key economic advantages:

- Cut-to-fit customization reduces material waste and guarantees you're only using what you need

- Lower initial investment compared to other protective materials, with considerable long-term savings through reduced component failure

- Versatile thickness and size options let you create efficient packaging designs that minimize costs

- Reusable and recyclable properties decrease your waste disposal expenses

You'll appreciate how pink foam's closed-cell structure and anti-static properties provide reliable protection without breaking the bank. Its ability to be thermoformed and die-cut means you can create precise fits for your components while maintaining cost efficiency.

The foam's durability guarantees it maintains its protective properties throughout shipping and storage, making it a smart investment for your electronic component protection needs.

Frequently Asked Questions

Can Pink Anti-Static Foam Lose Its Protective Properties if Exposed to Sunlight?

Yes, you'll find that sunlight exposure can degrade the anti-static additives in your pink foam. When exposed to direct sunlight, it'll lose its static-dissipative properties, even if it looks unchanged visually.

How Often Should Pink Anti-Static Foam Packaging Be Replaced?

You'll need to replace pink anti-static foam regularly, typically every 12-24 months. However, you should monitor it frequently and replace it sooner if you notice physical wear, discoloration, or degraded ESD properties.

Is Pink Anti-Static Foam Safe for Direct Contact With Bare Circuit Boards?

Yes, you can safely place bare circuit boards in direct contact with pink anti-static foam, as long as it's within its shelf life. The foam's static dissipative properties protect your electronics from harmful charges.

Does Cutting Pink Anti-Static Foam Affect Its Static-Dissipative Properties?

No, you don't need to worry about cutting pink anti-static foam. It'll maintain its static-dissipative properties since the protective additives are throughout the material, not just on the surface. Your cuts won't affect performance.

Can Pink Anti-Static Foam Be Cleaned Without Damaging Its Protective Qualities?

You shouldn't attempt to clean pink anti-static foam as any cleaning method could damage its protective properties. It's best to replace the foam when it's dirty or has reached the end of its shelf life.

In Summary

You've now seen how pink anti-static foam serves as your electronics' ultimate guardian. With its proven static discharge protection, customizable shapes, and remarkable cushioning abilities, it's a smart investment for your sensitive components. Whether you're storing, shipping, or handling delicate electronics, this versatile material delivers reliable protection while remaining cost-effective and environmentally conscious. Make pink foam your go-to solution for safeguarding valuable electronic items.

Leave a Reply