Humidity control stops static electricity buildup because water vapor molecules in the air act as natural conductors, giving excess electrical charges a safe path to ground. When you maintain relative humidity above 40%, the moisture creates invisible conductive films on surfaces that allow stray electrons to flow away instead of accumulating. That's why you experience more static shocks in winter when indoor heating dries out the air. The ideal range is 40-60% relative humidity, with levels above 55% completely preventing static buildup. Understanding how humidity affects static charges can help you better control these pesky electrical phenomena.

Static Electricity Fundamentals

In everyday life, static electricity occurs when electrons transfer between objects through physical contact or friction. You'll notice this phenomenon when you rub a balloon against your hair or walk across a carpet in socks – one surface gains electrons while the other loses them, creating an imbalance of electrical charges. Static generation can also occur from rapid temperature changes.

When you have two materials with different electrostatic properties that come into contact and then separate, one surface will retain extra electrons (becoming negatively charged) while the other surface loses electrons (becoming positively charged). You can observe this process clearly when peeling adhesive tape, as electrons from the surface stick to the tape, creating an electrical charge.

This charge buildup remains until it finds a path to discharge, typically through a conductive material like metal. When you touch a doorknob after walking across a carpet, you're experiencing this discharge as a tiny spark.

The accumulated static electricity always seeks to equalize, and it will discharge when it finds a suitable path to ground. Understanding these fundamentals helps explain why controlling environmental conditions, particularly humidity, is essential for managing static electricity in both homes and industrial settings.

The Science Behind Humidity Control

When you're dealing with static buildup, moisture in the air acts as a conductor that safely transfers excess charges to ground.

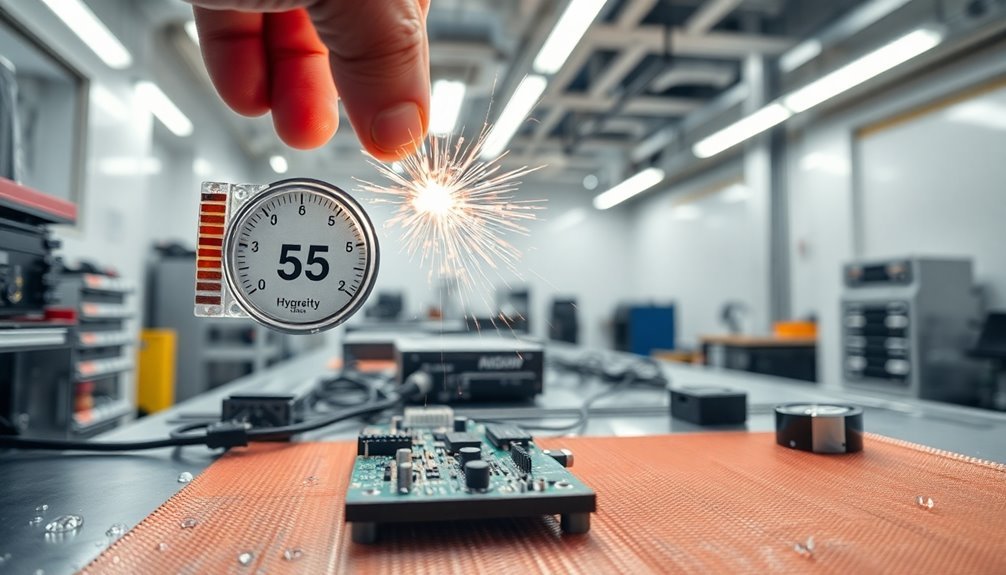

The water molecules form thin, conductive films on surfaces, allowing stray electrons to flow rather than accumulate. Maintaining relative humidity above 55% prevents static electricity from building up in the first place.

You'll find that air particles in a properly humidified environment can effectively transfer and neutralize electrical charges before problematic static levels develop.

Moisture Conducts Stray Charges

Understanding how moisture conducts stray charges stands out as a key principle in static control systems. When you maintain relative humidity levels between 40-60%, you'll find that air moisture acts as a natural conductor, effectively earthing potential static charges before they can accumulate.

Static electricity only builds up in environments where humidity drops below 40% RH. This happens because there isn't enough moisture in the air to conduct and dissipate the charges naturally. Research shows that water vapor charges surfaces through molecular collisions and friction.

When you increase humidity above 55%, you'll eliminate static buildup completely, as the moisture provides a consistent path for charges to disperse.

You can't ignore local conditions, though. Even in generally humid environments, hot machinery can create dry air pockets where static problems persist. That's why you'll need to pay attention to both overall humidity levels and specific problem areas.

When electric fields are present, they work together with humidity to trigger charge transfer between insulators, particularly through water adsorption on surfaces. This process happens because moisture in the air helps separate and transfer ions, creating a natural mechanism for static dissipation.

Air Particles Transfer Energy

The molecular behavior of air particles directly shapes how static charges dissipate in controlled environments. When you understand how water vapor conducts electricity, you'll see why maintaining proper humidity levels is essential for preventing static buildup.

Air particles, particularly water molecules, act as natural conductors that help distribute and relieve excess charges throughout your space. Low conductivity materials are especially prone to generating static electricity without proper humidity control.

In environments with adequate humidity levels, you'll notice how static charges dissipate through a series of important processes:

- Water vapor molecules in the air naturally conduct electricity, allowing charges to transfer safely between surfaces without sudden discharges

- When relative humidity stays above 55%, the air's increased conductivity prevents static charges from accumulating in the first place

- The presence of moisture molecules creates continuous pathways for charges to flow, eliminating the need for direct contact between conducting surfaces

- Higher humidity levels guarantee that triboelectric charges from friction dissipate rapidly instead of building up to dangerous levels

You'll find that maintaining proper humidity not only protects your equipment and products but also creates a safer working environment by preventing the conditions that lead to static electricity buildup.

Dry Air and Static Charges

Most people have experienced the shocking effects of static electricity during dry winter months. What you mightn't know is that there's a direct connection between humidity levels and static buildup. When relative humidity drops below 40%, you'll notice more static electricity in your environment.

You can blame this on the lack of moisture in dry air. Humidity acts as a natural conductor, helping to neutralize static charges that accumulate on surfaces. When the air's too dry, there's nothing to help dissipate these charges, leading to those unexpected zaps when you touch doorknobs or shake hands. Lower temperatures can actually help eliminate static electricity more quickly when absolute humidity stays constant.

Once humidity rises above 55%, you won't experience static buildup at all.

The reason humidity works so well against static is simple: moisture in the air increases electrical conductivity and decreases electrical resistance. This means any static charges that form will quickly dissipate instead of building up.

You can combat static electricity by using evaporative humidifiers or air purifiers with humidifying features to maintain ideal humidity levels between 40% and 60%. Removing carpets and managing heat sources can also help reduce static buildup in your space.

Moisture as Nature's Static Guard

Nature provides an elegant solution to static electricity through moisture in the air. When humidity levels rise above 55%RH, you'll notice a significant reduction in static buildup because water molecules act as natural conductors, allowing charges to dissipate quickly through the environment.

This natural phenomenon makes moisture one of your most effective tools for managing static electricity in both industrial and everyday settings. Low humidity environments under 45% relative humidity are particularly prone to static issues, especially near heat-generating equipment.

You can harness moisture's static-fighting properties through strategic humidification, which works by:

- Creating a conductive pathway that helps charges flow and neutralize

- Maintaining consistent humidity levels to prevent dry spots where static tends to accumulate

- Accelerating the natural discharge of static electricity through increased conductivity

- Providing a protective barrier against new static buildup on surfaces

In manufacturing environments, you'll find this principle at work through various humidification systems, from room-wide solutions to localized spray nozzles. Studies confirm that proper humidity control can reduce static charges by up to 98%, making it particularly valuable in sensitive industries like electronics, printing, and pharmaceuticals where static discharge can damage equipment or compromise product quality.

Optimal Humidity Levels

Successfully controlling static electricity requires maintaining specific humidity levels in your environment. You'll need to keep relative humidity (RH) above 55% to completely eliminate static buildup, though you'll notice some reduction once levels reach 40%. Below 40% RH, static electricity forms readily and can cause problems in sensitive environments.

When the air reaches its dew point temperature, condensation begins to occur, which helps dissipate static charges. The effectiveness of humidity control depends on several factors you'll need to monitor. Temperature plays a vital role since warmer air can hold more moisture.

Your HVAC system, ventilation, and building insulation all affect how well you can maintain ideal humidity levels. You'll also need to think about occupancy levels, as human activity can increase moisture in the air.

If you're managing industrial spaces or manufacturing facilities, you have several options for humidity control. You can use evaporative humidifiers for large areas or install localized spray systems near heat-generating machines.

Advanced technologies like dry fog systems offer precise control and energy efficiency. For the best results, you'll want to integrate these solutions with your existing HVAC system while monitoring temperature and absolute humidity levels to maintain the ideal environment for static prevention.

Industrial Static Prevention Methods

Industrial facilities employ multiple layers of static prevention to protect sensitive equipment and guarantee workplace safety. The most fundamental approach combines bonding and grounding systems with proper humidity control, creating a thorough defense against static buildup.

You'll find these critical static prevention methods in modern industrial settings:

- Bonding and grounding clips establish metal-to-metal connections, providing a direct path to earth that prevents charge accumulation on equipment and personnel.

- Humidity control systems maintain levels above 55%RH, using both room-wide humidifiers and localized spray systems to create protective micro-climates around sensitive machinery.

- ESD-safe clothing and PPE certified to EN 1149-5 standards protect workers while preventing static discharge risks in sensitive areas like cleanrooms and pharmaceutical facilities.

- Specialized treatments and equipment, including ionization systems and antistatic additives, offer additional protection layers where needed.

You can enhance these primary methods with supplementary measures like inerting processes with non-reactive gases or relocating static-sensitive operations. When you combine these approaches strategically, you'll create a robust static prevention system that safeguards both equipment and personnel.

Enhancing these methods involves several considerations:

Inerting processes with non-reactive gases can help avoid sparks in areas where they are likely to occur. This is particularly useful in environments where the risk of ignition is high.

Relocating static-sensitive operations to areas with better humidity control or using localized humidification can also mitigate static risks.

Seasonal Static Challenges

Static electricity challenges intensify during seasonal weather changes, particularly in the shift between warm and cold months. You'll notice this most during winter when indoor heating systems reduce humidity levels, creating perfect conditions for static buildup.

As outdoor temperatures drop, the air's ability to hold moisture decreases, making it harder to maintain ideal humidity levels inside your home or workplace.

You'll face the greatest static challenges when moving between environments with different humidity levels. For example, you might experience more static shocks when entering a heated building from the cold outside air.

To combat these seasonal variations, you'll need to adjust your humidity control strategies throughout the year. During winter months, you should maintain indoor humidity levels above 55% using humidifiers or other moisture-adding methods.

You can monitor these seasonal patterns by paying attention to when static problems become more frequent. Installing humidity monitoring devices will help you track changes and adjust accordingly.

Remember that your static control needs will vary substantially between seasons, so you'll need to adapt your approach as temperatures and humidity levels naturally fluctuate throughout the year.

Humidification System Types

Modern humidification systems offer diverse solutions for controlling static electricity across different environments. You'll find these systems particularly effective when they maintain humidity levels above 55%RH, effectively preventing static buildup in industrial, commercial, and residential spaces.

For large-scale applications, you can choose from several proven technologies:

- High-pressure spray systems that create a fine mist using hydraulic or pneumatic methods, offering efficient coverage for industrial spaces.

- Ultrasonic humidifiers that generate tiny water particles through vibration, providing precise control and energy efficiency.

- Adiabatic systems that combine humidification with cooling effects, ideal for air handling units.

- Centrifugal humidifiers that use spinning disks to atomize water, perfect for consistent moisture distribution.

You'll also find specialized solutions like MicroCool systems that use sensors for precision control, and localized spray systems designed specifically for hot machinery areas.

For smaller spaces, you've got options ranging from traditional sponge systems to modern electronic humidifiers with precise controls.

Many facilities now use centralized steam distributors or adiabatic humidifiers in their duct systems, ensuring consistent humidity throughout the building.

Manufacturing Environment Static Control

Anyone working in manufacturing knows the critical importance of controlling static electricity. You'll find that uncontrolled static can profoundly impact your operations, causing machinery malfunctions, product defects, and potential safety hazards.

When static charges build up, they can create dangerous sparks and attract dust contamination, directly affecting your product quality and productivity.

To effectively manage static in your manufacturing environment, you'll need to implement multiple control methods. Start by maintaining relative humidity above 55%, as this prevents static buildup by allowing charges to dissipate through water molecules in the air.

You should also establish proper grounding and bonding systems to safely discharge static electricity to the earth. Installing ionization equipment helps neutralize charges on non-conductive surfaces, while anti-static materials in your production line provide additional protection.

Don't forget to address localized issues, particularly around heat-generating equipment that creates dry microclimates. You'll want to use static control mats, bars, and appropriate PPE to protect both workers and products.

Remember to train your employees on static control practices, as their understanding and compliance are vital for maintaining a static-free manufacturing environment.

Precision Humidity Management Solutions

You'll find that smart monitoring systems seamlessly integrate with your facility's control networks to provide real-time humidity data across multiple zones.

Your automated control systems can respond instantly to these measurements through solenoid-controlled nozzles and high-pressure manifold lines, maintaining precise humidity levels where needed.

Smart Monitoring Systems Integration

In light of today's precision requirements, smart monitoring systems have revolutionized humidity control through advanced sensor technology and automated management solutions. These systems integrate seamlessly with your existing HVAC infrastructure, offering real-time monitoring and precise control over humidity levels to prevent static buildup.

They provide minute-by-minute humidity updates through devices like SensorPush, allowing you to maintain ideal moisture levels that prevent static electricity formation.

They'll automatically trigger your HVAC system when humidity levels drop too low, maintaining the 40-60% relative humidity range that's most effective for static control.

You'll receive instant alerts on your mobile device when conditions become favorable for static buildup, enabling quick corrective actions.

They integrate with IoT platforms for thorough environmental control, letting you adjust humidity levels remotely.

Modern smart monitoring systems offer several key advantages for static prevention:

- They provide minute-by-minute humidity updates through devices like SensorPush, allowing you to maintain ideal moisture levels that prevent static electricity formation.

- They'll automatically trigger your HVAC system when humidity levels drop too low, maintaining the 40-60% relative humidity range that's most effective for static control.

- You'll receive instant alerts on your mobile device when conditions become favorable for static buildup, enabling quick corrective actions.

- They integrate with IoT platforms for thorough environmental control, letting you adjust humidity levels remotely.

Automated Control Zone Planning

Through strategic zone planning, automated control systems revolutionize precision humidity management across diverse facility spaces.

You'll find advanced sensors strategically positioned throughout your facility, continuously monitoring temperature and humidity levels to provide real-time data for precise system adjustments.

The centralized control systems let you manage conditions remotely while utilizing AI-driven tools that anticipate environmental changes. You're able to integrate these controls seamlessly with existing HVAC systems through user-friendly interfaces that give you complete oversight of your facility's humidity levels.

Each zone operates with independent humidification units, including high-pressure fogging systems that you can tailor to specific requirements. You'll benefit from dedicated pump units and manifold lines that guarantee precise control while reducing overall system strain and extending equipment life.

The system's scalability means you won't need to overhaul everything when your needs change. You can easily expand or reconfigure zones as your operation grows, while multi-variable control systems automatically manage multiple parameters.

The model predictive control systems analyze patterns and adapt to changing humidity loads, securing consistent static prevention across all zones.

Preventive Static Maintenance Strategies

A thorough preventive maintenance strategy forms the foundation of effective static control in industrial environments. You'll find that implementing a detailed maintenance program helps identify potential static issues before they cause significant problems.

By using computerized maintenance management systems (CMMS), you can efficiently track and schedule necessary preventive tasks while maintaining ideal humidity levels.

To establish an effective preventive maintenance routine, follow these key steps:

- Conduct regular inspections of areas near heat-generating equipment, as these zones often create dry micro-climates that encourage static buildup.

- Monitor humidity levels consistently, ensuring they stay between 45-55%RH, with ideal control achieved above 55%RH.

- Implement predictive maintenance techniques using data analysis to anticipate potential static-related issues.

- Train your maintenance team in current technologies and best practices for static control.

You'll need to focus on continuous improvement practices to refine your maintenance strategies over time. This includes regularly updating your procedures based on collected data and observed patterns.

Frequently Asked Questions

Can Static Electricity Affect Wireless Signals and Internet Connectivity?

Yes, static electricity can disrupt your wireless signals and internet connectivity. You'll notice it can interfere with equipment, damage antennas, and cause data loss in network devices through electrostatic discharge.

Does Wearing Certain Types of Jewelry Increase Static Electricity Risks?

Yes, your metal jewelry can substantially increase static electricity risks. When you wear conductive items like necklaces and earrings, they create additional discharge points and can transfer static charges to sensitive electronic components.

Why Do Some People Experience More Static Shocks Than Others?

You'll experience more static shocks if you wear synthetic fabrics, have dry skin, or live in low-humidity areas. Your daily activities, like friction from movement and clothing choices, also affect your static buildup.

Can Static Buildup Damage Stored Data on Electronic Devices?

Yes, your stored data is at risk from static discharge. You'll find that static electricity can corrupt files and damage storage devices by causing short circuits and disrupting the electronic components that store information.

Does Static Electricity Affect Plant Growth in Indoor Environments?

Yes, static electricity affects your indoor plants, but not always positively. You'll want to avoid high static fields above 10kV, as they can harm plants rather than provide the beneficial effects seen in controlled experiments.

In Summary

You'll find humidity control is your best defense against static electricity. When you maintain proper moisture levels in the air, you're creating a natural conductor that helps dissipate static charges before they build up. By keeping relative humidity between 40-60%, you're ensuring those pesky electrons have a path to ground instead of jumping between surfaces. Remember, consistent humidity management isn't just comfort—it's essential protection for sensitive equipment.

Leave a Reply