You'll need to monitor anti-static measures during electronics manufacturing because ESD damage affects 60-90% of components without showing immediate failure. Your production line faces invisible static threats that can greatly reduce product lifespan and lead to substantial financial losses – the electronics industry loses over $84 billion annually due to ESD. By implementing proper monitoring systems, you can save 4-8% in annual revenues and reduce defect rates from 14.61% to 6.12%. Effective static control measures not only protect sensitive components but also guarantee compliance with critical standards like ANSI/ESD S20.20. Exploring these preventive strategies can transform your manufacturing outcomes.

Component Protection During Manufacturing

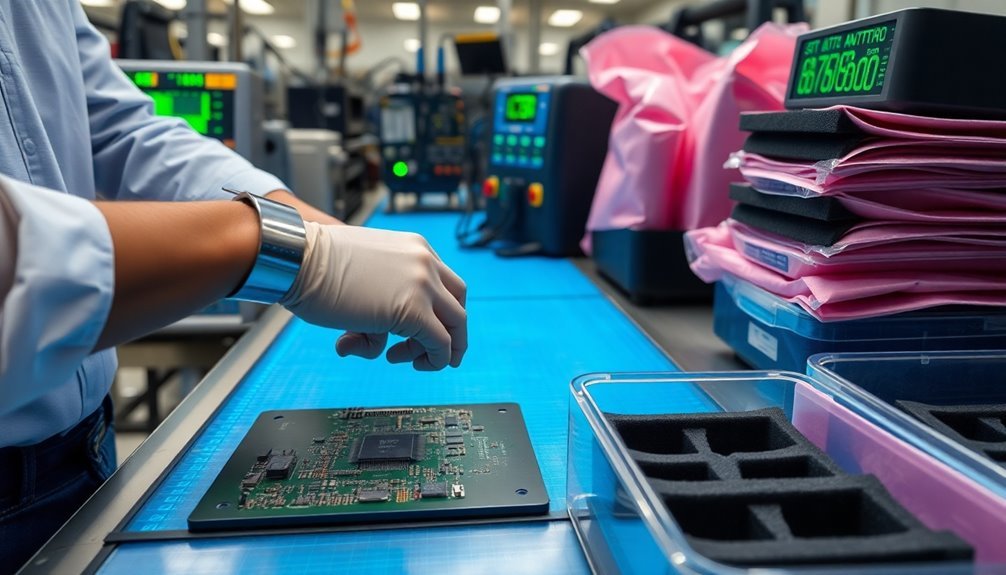

Throughout all of electronics manufacturing, protecting sensitive components from electrostatic discharge stands as a critical priority.

You'll need to implement multiple protective measures since ESD damage often goes undetected and can affect 60-90% of components without causing immediate failure. These invisible threats can greatly reduce your product's lifespan and lead to substantial financial losses.

To safeguard your components during manufacturing, you'll want to establish dedicated Electrostatic Discharge Protected Areas (EPAs) where you'll control all materials and surfaces. Advanced materials like silicone, epoxy, and urethane offer varying levels of protection based on specific application needs.

You should employ potting and encapsulation techniques, using resinous materials that protect sensitive electronics through various curing methods like air drying, oven drying, or UV light exposure. For peak protection, you'll need to select encapsulation compounds based on specific risk factors and required protection levels.

Don't forget to maintain humidity levels between 40-70% in your manufacturing area and make sure your team uses proper antistatic equipment, including bags with metal layers, conductive floor mats, and anti-static clothing.

You'll also need to implement regular inspections to monitor ESD levels and verify that all grounding systems and protective measures remain effective.

Cost Benefits of Static Control

Implementing effective static control measures can dramatically boost your company's bottom line, with potential savings of 4-8% in total annual corporate revenues. When you consider that the international electronics industry loses over $84 billion annually due to ESD, you'll understand why proper static control is essential for your manufacturing success.

You'll see significant cost reductions across multiple areas. You'll save on rework and repair costs, reduce material waste, and extend your equipment's lifespan. Your after-sale support costs will decrease due to fewer product failures. Quality control expertise from ECM partnerships helps maintain consistent static protection standards. By reducing ESD-related costs by 80%, you can add approximately 5% profit to your bottom line without increasing sales.

Process optimization through static control delivers measurable improvements. You can reduce defect rates from 14.61% to 6.12% and cut raw material waste by 29.6%. Your output can increase by 30.12% without additional input needs.

You'll also benefit from energy savings, potentially reaching 210 MWh annually. To maximize these benefits, you'll need expert consultation and a thorough evaluation of your manufacturing processes, ensuring your static control measures align with industry standards while addressing your specific needs.

Industry Compliance Requirements

While cost savings drive ESD control adoption, strict industry standards define the requirements you'll need to meet. Key regulations like ANSI/ESD S20.20, IEC 61340-5-1, and JEDEC JESD625B establish specific guidelines you must follow to protect electronic components. If you're working with defense contracts, you'll also need to comply with MIL-STD-1686.

You'll need to implement thorough grounding systems throughout your facility, including ESD-safe workstations, tools, and employee equipment. Your compliance program must include antistatic materials, environmental controls, and proper training for all personnel handling sensitive components. Maintaining proper humidity levels helps reduce static buildup in the manufacturing environment.

You'll also need to establish controlled access areas where ESD-sensitive work takes place.

To maintain certification, you'll need to conduct regular testing and auditing. This includes surface resistivity testing, charge decay measurements, and quarterly compliance checks.

You must carefully select ESD-safe materials for your manufacturing processes, from specialized plastics to static-dissipative flooring. Your packaging solutions need to meet strict standards for both storage and transportation.

Workplace Safety Through ESD Management

A well-structured ESD safety program protects both your workers and sensitive electronic components.

You'll need to start by creating a thorough safety plan that outlines specific protocols and identifies high-risk areas within your facility. Initial investment in proper ESD measures leads to long-term cost savings. Establish clear standard operating procedures and define Electrostatic Protected Areas (EPAs) where you'll handle sensitive items.

Your employees are your first line of defense against ESD damage. Make sure they receive extensive training on proper grounding procedures and the correct use of anti-static equipment like wrist straps and conductive clothing.

You'll want to implement regular testing and monitoring to verify compliance with established protocols.

Environmental controls play an essential role in your ESD management strategy. Maintain humidity levels between 40-70%, install properly grounded floors, and use conductive materials for work surfaces.

You should also minimize the presence of insulating materials in static-sensitive areas.

Don't let your ESD program become stagnant. Conduct regular audits, provide refresher training, and stay current with new ESD safety technologies.

Establish feedback mechanisms so your employees can report concerns and contribute to continuous improvement efforts. Regular maintenance of ESD control equipment guarantees long-term effectiveness of your safety measures.

Quality Assurance Best Practices

To maintain excellence in electronics manufacturing, you'll need to establish rigorous testing standards that align with industry protocols like IPC and follow consistent inspection methods throughout your production process.

You should implement systematic quality checks at critical stages, including incoming materials inspection, in-process testing, and final product verification. Regular employee training programs are essential to ensure proper execution of quality control procedures.

Your quality assurance program must include clear documentation of testing procedures, acceptance criteria, and specific inspection points to guarantee reliable detection of potential defects and ESD-related issues.

Testing Standards Protocol

Establishing effective testing standards protocol begins with the implementation of internationally recognized ESD testing methods, particularly IEC 61000-4-2. You'll need to guarantee your testing procedures align with industry-specific standards, such as EN 60601-1-2 for medical devices or ISO 10605 for automotive products.

When you're conducting ESD testing, you must maintain strict control over temperature and humidity in your testing environment to achieve reliable results. You'll want to use specialized equipment to simulate both human body and machine model electrostatic discharges, determining your products' ESD withstand voltage through precise pulse testing.

You should regularly test and maintain your grounding systems while implementing thorough incoming material inspections to catch potential issues early. Consider incorporating protective TVS devices to enhance your products' resilience against static charges.

It's vital to conduct in-process inspections throughout manufacturing to detect any deviations from quality standards. You'll need to train your employees on proper testing procedures and maintain extensive documentation of all test results.

Don't forget to establish clear acceptance criteria based on your industry's requirements. Make sure you're consistently monitoring and recording test data to validate your anti-static measures' effectiveness and maintain compliance with relevant standards.

Inspection Methods Assessment

Implementing effective inspection methods requires a strategic balance between surface and volume resistivity testing. While volume resistivity measures bulk electrical properties, it's not reliable as a standalone indicator due to surface effects and material contamination.

You'll find surface resistivity testing more valuable for evaluating anti-static properties, though you must still account for potential surface layer inconsistencies.

You need to establish thorough inspection procedures at every manufacturing stage. Start with thorough incoming material checks, followed by regular in-process inspections to maintain quality standards. Proper analysis must consider material purity levels to ensure consistent performance.

It's crucial to verify that your anti-static equipment, including floor mats and wrist straps, functions properly to prevent static buildup during production.

Your ESD control strategy should incorporate multiple layers of protection. You'll want to maintain appropriate temperature and humidity levels while ensuring all personnel wear proper anti-static clothing.

Don't forget to implement regular training sessions to keep your team updated on ESD guidelines. Remember to extend your anti-static measures to packaging materials, protecting components even after they leave your facility.

Regular evaluations of these control measures will help you maintain consistent ESD protection throughout your manufacturing process.

Environmental Monitoring Systems

Since maintaining precise environmental conditions is essential in electronics manufacturing, Environmental Monitoring Systems (EMS) serve as the backbone of quality control and process optimization.

You'll find these systems equipped with various sensors that continuously monitor temperature, humidity, pressure, and air quality – all critical factors that can affect static electricity levels and component integrity. The system's touch screen interface allows operators to quickly respond to environmental changes.

Your EMS will typically include temperature and humidity sensors connected to microcontrollers that process the data in real-time. Through wireless transceivers, this information is transmitted to your central monitoring station, where you can analyze trends and receive instant alerts if conditions fall outside acceptable ranges.

You'll benefit from the system's ability to provide historical data analysis, helping you identify patterns and optimize your manufacturing processes. The EMS guarantees you're compliant with industry standards while protecting sensitive electronic components from environmental damage.

You can prevent costly downtime and improve product reliability by maintaining proper environmental conditions.

For your electronics manufacturing facility, implementing an EMS isn't just about meeting regulations – it's about protecting your investment and guaranteeing consistent product quality through precise environmental control and monitoring.

Static Control Equipment Maintenance

You'll need to follow a strict testing protocol to guarantee your static control equipment meets industry standards and remains effective over time.

Your equipment calibration standards must align with ANSI/ESD S20.20-2014 requirements, including regular checks of wrist straps, mats, and ionizers for proper resistance levels and grounding capabilities.

Implementing a preventive maintenance schedule that includes quarterly inspections, annual audits, and three-year thorough testing will help you maintain ideal static protection in your electronics manufacturing facility.

Regular Testing Protocol

A manufacturing facility's regular testing protocol forms the backbone of effective static control maintenance. You'll need to conduct systematic inspections of all static control equipment, including regular checks of grounding systems and ionizer efficiency testing.

Your protocol should include daily testing of personal grounding devices like wrist straps and heel straps to guarantee proper functionality.

To maintain compliance with ANSI/ESD S20.20 standards, you must document all testing procedures and results meticulously. You'll want to establish clear maintenance schedules and keep detailed records of every inspection and test you perform.

It's essential to implement a monitoring system that tracks performance metrics and identifies areas needing improvement.

Don't forget to train your employees on proper testing procedures and encourage their feedback on the effectiveness of your static control measures.

You should regularly audit your testing protocols to make sure they're meeting industry standards and update them as needed.

When equipment fails testing or doesn't meet performance criteria, you'll need to follow established replacement procedures.

Remember to properly store and dispose of any equipment that no longer functions effectively to prevent accidental use of faulty devices.

Equipment Calibration Standards

Maintaining precise calibration standards for static control equipment stands at the core of your ESD protection strategy. You'll need to follow manufacturer recommendations closely while guaranteeing all calibration processes are documented and tracked within your facility's maintenance program.

Regular calibration helps you verify that your static control equipment can effectively detect and neutralize charges in your manufacturing environment.

Key aspects of equipment calibration you shouldn't overlook:

- Your ionizers must be calibrated to maintain the correct balance of positive and negative ions, with regular checks on emitter condition and airflow performance.

- Your static meters require sensitivity and accuracy verification to guarantee they're detecting charge levels correctly.

- Your grounding systems need consistent resistance testing to confirm they meet required standards.

- Your testing equipment must align with current industry standards, particularly ANSI/ESD S20.20.

You'll want to integrate your calibration schedule into your facility's preventive maintenance program. This integration guarantees you're not missing critical calibration windows and helps maintain compliance with industry standards.

Keep detailed records of all calibration activities, as they're essential for audit purposes and help track equipment performance over time.

Preventive Maintenance Schedule

Building an effective preventive maintenance schedule for static control equipment requires careful planning and consistent implementation across your facility. You'll need to establish daily checks that include visual inspections, testing of static control devices, and verification of proper grounding equipment function. Remember to maintain detailed log entries for tracking these inspections.

| Maintenance Level | Key Tasks | Frequency |

|---|---|---|

| Basic Inspection | Visual checks, wrist strap testing | Daily |

| Equipment Testing | Ground connections, mat resistance | Weekly |

| Deep Maintenance | Calibration, parts replacement | Quarterly |

To enhance your maintenance schedule, you'll want to prioritize tasks based on asset criticality and manufacturer guidelines. Don't forget to align PM schedules with production downtime to minimize disruption. You can boost efficiency by grouping related maintenance tasks and implementing automated scheduling tools.

Your preventive maintenance program should include a thorough inventory of all static control equipment, standardized checklists, and detailed maintenance records. You'll need to continuously refine your PM triggers through root cause analysis of equipment failures and regular review of performance data to provide maximum protection against static damage in your manufacturing process.

Production Line Risk Assessment

Production line risk evaluation forms the foundation of effective electronics manufacturing safety protocols. You'll need to identify, quantify, and prioritize potential risks to guarantee your manufacturing processes remain reliable and efficient.

When examining your production line, focus particularly on ESD-related risks that can severely impact sensitive electronic components.

To effectively evaluate risks in your production line, consider these critical factors:

- Potential impact on production schedules and costs based on historical data

- Probability of risk occurrence using statistical analysis

- Severity of possible equipment damage or product failures

- Compliance requirements with international ESD standards

You'll want to use proven evaluation tools like FMEA and risk matrices to calculate risk scores accurately.

By implementing IIoT monitoring systems, you can collect real-time data to identify emerging risks before they cause significant problems.

Remember to analyze both the immediate and long-term consequences of each identified risk, paying special attention to areas where ESD protection might be compromised.

Your risk evaluation should also factor in the cost implications of potential failures versus the investment required for preventive measures.

Employee Training for ESD Prevention

Through thorough training programs, you'll need to guarantee your employees understand and consistently apply ESD prevention measures in your electronics manufacturing facility.

Your training curriculum should cover essential topics like ESD fundamentals, its impact on electronic components, and proper control measures including grounding and bonding techniques.

You'll want to implement both theoretical and hands-on training methods to ensure extensive learning.

Start with classroom sessions on ESD principles, then move to practical exercises where employees can practice using wrist straps, gloves, and other PPE correctly.

Include simulated scenarios that let workers experience real-world ESD prevention situations in a controlled environment.

Data Collection and Analysis

Data collection lies at the heart of effective ESD control, enabling you to monitor, analyze, and improve your anti-static measures across all manufacturing processes. By implementing regular ESD audits and real-time monitoring systems, you'll identify potential risks before they cause costly damage to your electronic components.

Modern IoT-integrated devices and smart anti-static equipment make it easier than ever to gather essential data about static levels in your facility. You'll want to focus on these key aspects of data collection:

- Regular static level measurements using advanced static meters

- Continuous monitoring of humidity levels and grounding system performance

- Tracking ESD-related incidents and failures for trend analysis

- Real-time data collection from ionizing equipment and static eliminators

Through systematic data analysis, you can refine your ESD control strategies and guarantee compliance with standards like ANSI/ESD S20.20.

This data-driven approach helps you make informed decisions about protective measures, from adjusting humidity controls to upgrading anti-static equipment.

You'll also save money by preventing ESD-related failures and minimizing production downtime while maintaining consistent product quality throughout your manufacturing process.

Performance Metrics and Benchmarking

Setting meaningful performance metrics and benchmarks is essential for evaluating your anti-static measures' effectiveness.

You'll need to focus on key indicators like surface resistivity, which directly reflects your antistatic performance. For ideal ESD protection, verify your materials maintain surface resistance values between 10^4 to 10^6 ohms/square.

You should regularly monitor your anti-static mats' performance using ESD event detectors and static field meters. These tools provide real-time data on your protection measures' effectiveness.

When benchmarking, you'll want to take into account material factors that affect static properties, including purity, contamination levels, and moisture content.

Your industry requirements will determine the specific standards you need to meet. If you're working in precision electronics or IC manufacturing, you'll need conductive static materials that provide superior protection.

Remember that rubber mats offer excellent versatility and reliable static dissipation properties.

To maintain compliance with industry regulations, you must conduct regular audits and update your ESD control procedures. This systematic approach guarantees you're meeting the stringent requirements of electronics manufacturing while protecting sensitive components from harmful static discharge.

Frequently Asked Questions

How Often Should Anti-Static Equipment Be Calibrated and Recertified?

You'll need to calibrate and recertify your anti-static equipment annually, though you should check it monthly. If you're operating in harsh conditions or using it frequently, consider calibrating every six months instead.

Can Static Control Measures Interfere With Wireless Communication Devices?

No, you won't experience wireless interference from proper static control measures. While static discharges themselves can affect wireless devices, the measures used to prevent static actually help protect your wireless communications from disruption.

What Temperature and Humidity Ranges Are Optimal for Static Prevention?

You'll want to maintain temperatures between 18-22°C and keep relative humidity at 40-60% for ideal static prevention. These ranges help prevent ESD while avoiding moisture-related issues in your electronics manufacturing environment.

How Do Seasonal Changes Affect Anti-Static Control Effectiveness?

You'll notice seasonal changes greatly impact your anti-static controls. During winter, lower humidity and heating systems create drier conditions, increasing static risks. You'll need stronger ESD measures during cold months.

Are There Specific Storage Requirements for Anti-Static Materials When Not Used?

You'll need to store anti-static materials in controlled environments using proper containers. Keep them in anti-static bins, shielding bags, or conductive containers below 60% humidity and away from extreme temperatures while unused.

In Summary

Monitoring anti-static measures during electronics manufacturing isn't optional – it's crucial for your business success. You'll protect sensitive components, meet industry standards, and guarantee worker safety while reducing costly production errors. By implementing robust ESD monitoring systems and maintaining thorough documentation, you're safeguarding your production line and strengthening your quality control processes. Make ESD monitoring a cornerstone of your manufacturing strategy.

Leave a Reply