Grounded raised floors protect your data center through multiple integrated safeguards. You'll find anti-static materials working alongside proper electrical grounding to prevent equipment damage from static discharge and power surges. The floor's design incorporates a low-resistance path to earth, keeping electrical currents safely channeled away from your sensitive hardware. Your equipment benefits from reduced electromagnetic interference, better cable management, and improved airflow distribution through the raised floor structure. When combined with proper bonding and resistance testing below 1 ohm, these systems guarantee your critical infrastructure stays protected. Understanding each component's role will help you maximize your facility's protection.

Understanding Data Center Grounding Basics

Three fundamental aspects make data center grounding a critical infrastructure component: safety, protection, and performance. Proper grounding prevents electrical shocks by channeling unwanted currents safely into the earth, while simultaneously protecting your valuable equipment from damaging electrical surges and static discharge.

When you implement effective grounding systems, you're establishing a robust foundation that includes essential components like grounding electrodes, conductors, and bus bar systems. These elements work together to maintain uniform electrical potential throughout your facility. Regular testing methods validate the continued effectiveness of these grounding components.

You'll need to guarantee that all metallic parts are properly bonded to prevent potential differences that could lead to equipment damage or safety hazards.

Your data center's grounding system directly impacts operational efficiency by reducing voltage fluctuations and electromagnetic interference. It's vital to understand that grounding isn't just about meeting regulatory requirements – it's about creating a stable electrical environment that safeguards both personnel and equipment.

Essential Anti-Static Floor Components

A well-designed anti-static floor system requires several key components working together to protect your data center's sensitive equipment.

You'll need a seamless and smooth surface that minimizes dust and debris accumulation, which could otherwise compromise your facility's cleanliness and equipment safety.

Your anti-static flooring must incorporate chemical-resistant materials to maintain its structural integrity when exposed to spills, while also featuring impact resistance to withstand the movement of heavy equipment.

You'll find that proper dust control mechanisms are vital, as they reduce contamination risks that could affect your sensitive electronic components. The flooring must meet ANSI/ESD standards for reliable static control performance.

The flooring system should also include UV-stable materials to prevent degradation from prolonged light exposure.

When selecting your anti-static floor components, you'll want to focus on materials that offer multi-layered protection, including specialized primers, intermediate coats, and topcoats. These layers work together to create an extensive static dissipation system.

Don't forget to take into account the floor's flexibility – it should adapt to changing environmental conditions while maintaining its protective properties.

Your components must also support proper grounding connections through pedestals and stringers to guarantee continuous static dissipation throughout the raised floor system.

Grounding Network Design Principles

When you're planning your data center's grounding network, you'll need to think about the mesh layer configuration that best suits your raised floor's size and equipment layout.

The low impedance path to earth ensures proper dissipation of fault currents and surge protection for sensitive equipment.

You must install copper grids according to TIA-942 standards, ensuring proper bonding at intersections and strategic connection points to equipment racks.

Your resistance testing parameters should include measuring point-to-point continuity and verifying that the overall system impedance remains below 1 ohm, as specified by industry standards.

Mesh Layer Configuration Plans

Professional data center grounding networks require meticulous mesh layer configuration planning to guarantee reliable equipment protection and peak performance. You'll need to implement a carefully designed mesh network system that facilitates efficient data exchange while maintaining low latency across interconnected switches. This approach ensures predictable capacity delivery through distributed network designs, making it highly suitable for modern cloud services.

Your mesh layer configuration should incorporate a super spine architecture that effectively connects multiple Points of Delivery (PoDs). This setup guarantees predictable capacity and creates an essential signal reference grid for bonding all ground references to a common equipotential plane.

You'll want to integrate a three-tier model with core, aggregation, and access layers to optimize packet movement.

When implementing your mesh layer configuration, you must prioritize visual verifiability of all grounding components. Make certain you're creating low-resistance paths to ground and maintaining proper electrical potential equalization throughout the data center.

You'll need trained professionals to make reliable connections using high-quality materials that comply with standards like FIPS 94. Don't forget to establish a regular inspection schedule to verify the integrity of your grounding system, as continuous monitoring plays a vital role in maintaining its effectiveness and protecting your sensitive electronic equipment from electrostatic discharge.

Copper Grid Installation Methods

Through precise installation methods, copper grid networks form the backbone of effective data center grounding systems. You'll need to install parallel copper conductors with uniform spacing beneath the raised floor, providing thorough coverage across the entire facility.

When laying out your grid, it's vital to connect each equipment frame and metallic structure individually to the grounding electrode using appropriately sized copper conductors or straps. Having single-point grounding helps prevent harmonics and electrical noise from disrupting data center operations.

To implement an effective copper grid installation, follow these key steps:

- Select copper conductors between 6 AWG and 4/0 AWG based on your specific equipment requirements and expected fault currents.

- Lay conductors in a grid pattern with consistent spacing, extending beyond the perimeter to reduce surface potential gradients.

- Use low-emission exothermic welds for connections and guarantee proper bonding when running through ferrous metallic conduit.

You'll need to think about soil conditions carefully, as burying the grid in soil with good resistivity is essential for peak performance.

Remember to incorporate supplemental grounding for HVAC systems and static discharge protection, while maintaining proper bonding between all equipment frames and the main grounding system.

Resistance Testing Parameters

In modern data centers, resistance testing parameters serve as critical benchmarks for evaluating grounding network effectiveness.

You'll need to guarantee your ground cable resistance doesn't exceed 0.1 ohms, using either 5AWG (16mm2) or 3 AWG (25mm2) copper cables based on your installation's length requirements.

When you're testing connections to room ground, you must verify that each equipment frame and metallic structure maintains its individual connection to the ground electrode. Maintaining a grounding resistance below 4Ω is essential for protecting high-precision electronic equipment.

Your testing protocol should include measuring ground-fault current circulation through predetermined circuits to prevent random current paths that could damage sensitive equipment.

You'll want to pay special attention to the Signal Reference Grid (SRG), which bonds all ground references to a common equipotential plane. This system works in conjunction with anti-static raised floors, where electrically connected floor brackets form a thorough grounding net.

You must connect this grounding network to your building's independent copper grounding bars. Remember to maintain uniform signal ground connections and avoid connecting them to neutral wires, as this could compromise your data center's protection against electrical anomalies.

Static Protection Best Practices

When you're installing anti-static flooring in your data center, you'll need to carefully integrate the grounding system with both the raised floor structure and building steel to guarantee thorough protection.

You can minimize static discharge risks by selecting appropriate flooring materials that maintain consistent performance across varying humidity levels while meeting safety resistance requirements of at least 150 kilohms between any two points. For maximum effectiveness, ensure your flooring has electrical resistance below 10E7 to meet industry standards for static management.

Your grounding network should include a perimeter belt made of galvanized flat steel strip and properly spaced grounding wires that connect to all cabinets and floor brackets, creating a unified static protection system.

Anti-Static Floor Installation

The installation of anti-static flooring stands out as a critical component for protecting data center equipment against electrostatic discharge (ESD). You'll need to carefully assess your facility's requirements, including current and future equipment loads, cooling needs, and underfloor space requirements before beginning installation.

When you're installing anti-static flooring, focus on these essential steps:

- Choose appropriate materials that offer both antistatic properties and durability, confirming they comply with ANSI/ESD standards and building codes.

- Plan for modular designs that allow easy reconfiguration and future upgrades while maintaining proper airflow.

- Implement complementary static control measures, including ESD-safe equipment and grounded workstations.

Regular specialized cleaning techniques performed by experienced providers ensure optimal antistatic performance and equipment protection. You'll need to maintain your anti-static flooring regularly to guarantee its effectiveness. This includes conducting periodic conductivity checks, using appropriate cleaning products, and following a strict maintenance schedule.

Your floor's antistatic properties work together with other static control measures like ESD wrist straps and footwear to create a thorough protection system. By installing and maintaining proper anti-static flooring, you're substantially reducing the risk of equipment damage and downtime in your data center.

Static Discharge Risk Mitigation

Building upon proper anti-static floor installation, thorough static discharge risk mitigation requires a multi-layered approach to protect your data center equipment. You'll need to implement extensive measures that go beyond basic humidity control, as this alone won't adequately protect your sensitive electronics from ESD damage.

Start by equipping your staff with proper ESD footwear that works in conjunction with your ESD flooring system.

You'll want to maintain regular cleaning schedules for both your raised floors and ESD surfaces to guarantee their antistatic properties remain effective.

Install environmental monitoring systems to track conditions that might lead to static buildup, and guarantee your HVAC system is regularly calibrated to maintain ideal conditions.

Don't overlook the importance of proper cable management under your raised floors. You'll need to organize cables efficiently to prevent airflow obstacles that could contribute to static generation.

Train your staff thoroughly on ESD prevention protocols and the correct use of protective equipment.

By following ASHRAE guidelines for ESD mitigation, you can maintain wider temperature and humidity ranges while reducing energy consumption.

Remember to conduct regular inspections of your ESD systems to identify and address potential issues before they cause damage.

Grounding System Integration

Proper integration of your data center's grounding system stands out as the cornerstone of thorough static protection. You'll need to bond all ground references to a common equipotential plane while implementing a Signal Reference Grid (SRG) to guarantee high-frequency ground reference across your facility.

This integrated approach helps reduce equipment communication interference and provides a reliable discharge path for unwanted electrical energy.

To maximize your grounding system's effectiveness, you'll want to focus on these critical components:

- Install a detailed grounding grid that includes mesh networks and bonding grids, creating low-resistance paths for dissipating fault currents and static charges

- Set up grounding bus bar systems as central connection points, guaranteeing each equipment rack has proper grounding capabilities

- Implement supplemental grounding measures for HVAC and cooling systems to enhance overall protection

Don't forget to complement your grounding infrastructure with static control measures like ESD tiles and anti-static floor paint. You'll also need to equip workstations with ESD table mats and provide personnel with wrist straps connected to common ground points.

Regular testing and maintenance of these systems will guarantee continued protection against static-related risks.

Airflow Management Through Raised Floors

Effective airflow management through raised floors stands as a cornerstone of modern data center cooling strategies. Raised floors create a dedicated plenum space beneath your equipment, providing a direct path for cool air distribution while keeping cables and other potential obstructions out of the way.

You can maximize your cooling efficiency by utilizing perforated floor tiles and dampers, which allow you to control airflow precisely where it's needed. This system helps you eliminate hot spots and maintain consistent temperatures throughout your facility.

When you're routing cables and equipment beneath the floor, you'll reduce congestion and guarantee that cool air reaches your hardware without interference.

You'll notice significant improvements in your data center's overall performance through the implementation of hot/cold aisle containment strategies. The raised floor system lets you direct cool air exactly where it's needed, reducing energy waste and improving cooling effectiveness.

Load Distribution and Support

Load distribution and support represent three critical aspects of data center raised floor design. When you're planning your data center infrastructure, you'll need to carefully consider how weight loads are distributed across your raised floor system to guarantee both safety and operational efficiency.

Your raised floor's load-bearing capacity must align with industry standards, typically ranging from 7.2 kPa to 12 kPa, and you'll want to factor in future expansion needs. The floor's structural integrity depends on proper weight distribution and appropriate safety margins for unexpected situations.

To maximize your raised floor's effectiveness, consider these essential load management principles:

- Match your floor height to your application requirements: 4-6 inches for light-duty, 6-12 inches for medium-duty, and 12+ inches for heavy-duty installations.

- Guarantee even distribution of equipment weight across the floor space, considering both distributed and concentrated loads.

- Select appropriate support pedestals and floor materials based on your specific load requirements, whether you're building a light-duty facility (under 1,000 psf) or a heavy-duty data center (2,000+ psf).

Remember that proper load distribution isn't just about current needs – it's about maintaining flexibility for future growth and changes in your data center layout.

Grounding Safety Standards

You'll need to guarantee your data center's raised floor meets minimum grounding resistance levels of less than 1 ohm to ground, as specified by ANSI/TIA-942 standards.

Your metal components, including floor panels, pedestals, and stringers, must be properly bonded together to create a continuous ground path according to IEEE Std 1100-1992 requirements.

When installing grounding connections, you're required to use copper bus bars and approved connectors that comply with both local building codes and manufacturer specifications to maintain warranty validity.

Minimum Grounding Resistance Levels

While data center safety standards vary by jurisdiction, the minimum grounding resistance levels must meet specific thresholds to guarantee proper protection. You'll need to understand that most grounding systems should aim for resistance values of 5 ohms or less, as recommended by NFPA and IEEE.

However, for data centers with raised floors, you'll want to achieve even lower resistance levels, particularly if you're operating sensitive equipment or managing critical infrastructure.

For your data center's raised floor system, you should focus on these essential resistance requirements:

- Standard data centers require less than 5 ohms of ground resistance, though you'll want to aim for the lowest feasible value.

- Class F4 data centers must maintain 1 ohm or less, as specified by ANSI/BICSI 002 standards.

- Raised floor systems specifically shouldn't exceed 4 ohms of resistance, and you'll need to verify proper connection to the building's main grounding network.

You can achieve these resistance levels through proper implementation of grounding grids, mesh systems, and, when necessary, additional grounding piles. If you're using pile foundation reinforcement, you'll find it particularly effective at achieving low grounding resistance values.

Metal Bonding Requirements

Proper bonding of metallic components stands out as one of the most vital safety requirements in data center grounding systems. You'll need to guarantee that all metallic parts, including equipment racks, ladder racks, enclosures, and cable trays, are securely bonded to the grounding system using stranded copper conductors with green jackets.

When you're installing bonding conductors, you must route them carefully to prevent damage and secure them at both ends. It's imperative to use low-emission exothermic welds for conductors in ferrous metallic conduits, and you'll need to label each telecom grounding and bonding conductor for easy identification.

Your bonding network should incorporate a MESH-BN grid that covers the entire computer room space, typically spaced between 2 and 4 feet apart. You'll want to connect all metallic components to either the MESH-BN or RGB using appropriate conductors.

This thorough bonding approach creates an equipotential plane that prevents electrical shocks, protects sensitive equipment, maintains data integrity, and reduces electromagnetic interference. Remember that proper bonding isn't just about safety – it's also vital for meeting warranty requirements and compliance standards like TIA-607-B and TIA-942.

Grounding Connection Standards

Building on the metal bonding requirements, grounding connection standards provide the foundation for a thorough safety system in data centers. You'll need to guarantee your grounding system maintains a resistance of less than 1 Ohm and keeps data center equipment grounds separate from other building grounds to meet compliance requirements.

Following established standards like IEEE Std 1100-1992, you must focus on creating low-impedance grounding and bonding connections throughout your facility. FIPS 94 recommends implementing a signal reference structure (SRS) to maintain a high-frequency common ground reference for your equipment.

To meet these critical standards effectively, you'll want to:

- Verify compliance with all state and local codes for grounding installations

- Install independent grounding systems that don't share paths with other building grounds

- Implement proper monitoring systems to guarantee continuous compliance with the less-than-1-ohm resistance requirement

Your grounding connection standards aren't just about meeting regulations – they're essential for protecting your equipment and guaranteeing consistent operation. When you follow these standards correctly, you're creating a robust foundation for your data center's electrical safety system while maintaining top performance of your sensitive electronic equipment.

Cable Management Benefits

The benefits of effective cable management in data centers extend far beyond simple organization. When you implement proper cable management strategies, you'll see immediate improvements in your facility's efficiency and productivity. You can expect better airflow circulation, reduced risk of overheating, and streamlined maintenance processes that boost overall uptime.

Your data center's economic performance will improve as you'll spend less on operational costs and maintenance. With organized cabling systems, you'll quickly identify available capacity and plan for future growth while reducing the time spent on troubleshooting issues.

Under-floor cable management in raised floor systems provides you with easy access for maintenance and modifications.

You'll find that raised floors offer exceptional advantages for cable management. They create dedicated spaces for your cabling infrastructure while improving airflow distribution and cooling efficiency.

When you route cables under raised floors, you're not just organizing them – you're also protecting them within a grounded environment that safeguards your sensitive equipment. This setup allows you to easily reconfigure your infrastructure as needed, ensuring your data center remains adaptable to changing requirements while maintaining peak performance and reliability.

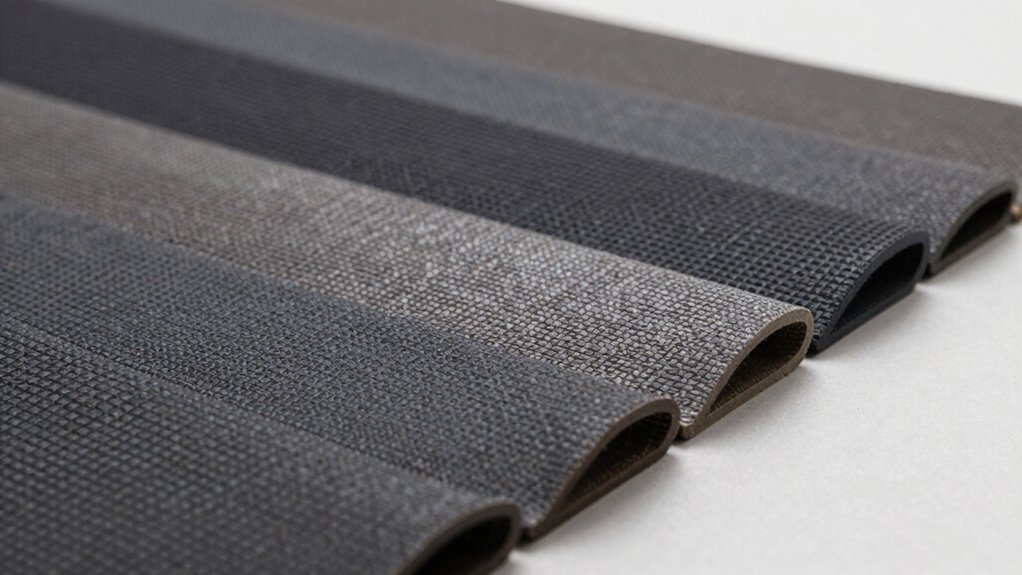

Material Selection Criteria

When designing a protected data center with raised floors, material selection directly impacts your facility's performance and safety. You'll need to prioritize materials that offer a thorough protection against electrostatic discharge, fire hazards, and environmental factors while maintaining compliance with building codes and safety standards.

For maximum protection, you should focus on these critical material selection criteria:

- Anti-static and Grounding Properties:

- Choose materials with proven anti-static finishes for floor tiles and guarantee they're compatible with your grounding system.

- Galvanized steel and copper wiring components will create an effective electrical connection network.

- Fire Safety and Durability:

- Select fire-rated panels and insulation materials that won't compromise your facility's safety.

- Your materials must withstand expected load densities while maintaining their protective properties over time.

- Thermal Efficiency and Modularity:

- Opt for perforated tiles that enhance airflow and reduce cooling costs.

- Consider modular designs that allow for future modifications while maximizing space utilization.

Remember that your material choices must align with electrical safety standards and environmental requirements. You'll want materials that protect sensitive equipment while contributing to your data center's overall sustainability and operational excellence.

Materials such as those described in raised floor systems can meet these criteria. For instance, raised floors often use a combination of materials like steel, aluminum, cement, and wood core, which provide the necessary structural integrity and can include anti-static properties to prevent electrostatic discharge.

Steel raised floor panels, made from galvanized steel with internal lightweight cement material, offer superior stability, rigidity, and durability. These panels are protected from corrosion and can be customized with various top coverings, ensuring they meet the required anti-static and grounding standards.

Fire-rated panels are essential to ensure the facility's safety by mitigating fire hazards. Compliance with standards such as those from the International Fire Code, National Fire Protection Association (NFPA), and Factory Mutual (FM) Global is crucial to prevent and manage fire risks efficiently.

Perforated tiles enhance airflow, which is vital for cooling and maintaining optimal server performance. Modular designs allow for easy reconfiguration and upgrades, ensuring the data center can adapt to technological advancements without significant structural changes.

Energy Efficiency Advantages

Installing grounded raised floors in your data center leads to substantial energy efficiency gains across multiple operational aspects. You'll achieve up to 40% reduction in cooling loads through optimized airflow management and enhanced air distribution.

The raised floor plenum creates a dedicated pathway for cool air delivery, eliminating obstructions and ensuring even temperature distribution throughout your facility.

You can maximize these benefits by implementing hot and cold aisle containment strategies, which become more effective with raised flooring. When you combine this infrastructure with AI-powered cooling systems and variable frequency drives, you'll see significant reductions in energy consumption and operational costs.

The segregation of hot and cold air streams minimizes energy wastage, contributing to a smaller carbon footprint.

Your cooling efficiency improves through the direct delivery of cold air to equipment, preventing hot spots that could compromise performance. You'll notice long-term cost savings from reduced energy consumption while maintaining ideal equipment temperatures.

This efficient cooling approach extends the lifespan of your IT assets and supports sustainable operations, helping you meet environmental stewardship goals while ensuring compliance with energy conservation standards.

Frequently Asked Questions

How Often Should Raised Floor Grounding Systems Be Tested and Recertified?

You'll need to test your raised floor grounding systems quarterly for electrical outlets and connections, while conducting annual resistance measurements. Don't forget to perform additional inspections before thunderstorm season for maximum protection.

What Happens if Lightning Strikes a Data Center With Grounded Floors?

When lightning strikes your data center, properly grounded floors will direct the surge into the earth, protecting your equipment. You'll still experience electrical disturbances, but the grounding system helps prevent catastrophic damage.

Can Existing Data Centers Retrofit Their Floors With Grounding Systems?

Yes, you can retrofit your data center's floors with grounding systems. You'll need to install grounding bus bars, mesh grids, and proper bonding connections while maintaining operations. It's complex but entirely feasible with proper planning.

Do Raised Floors Affect Wi-Fi Signal Strength in Data Centers?

No, you won't notice significant Wi-Fi signal impact from raised floors since signals travel through air. Your raised floor's primary functions are cable management and cooling, which actually help maintain top-notch Wi-Fi performance.

What Maintenance Costs Should Be Expected for Grounded Raised Floor Systems?

You'll need to budget $3-$5 per square foot for installation labor, plus annual costs of $1,000-$2,000 for inspections, static testing, and repairs. Regular cleaning services add $0.10-$0.30 per square foot.

In Summary

You've learned how grounded raised floors form a vital defense system for your data center. They'll protect equipment through proper static dissipation, maintain consistent airflow, and provide essential cable management. When you follow correct grounding standards and select appropriate materials, you'll create an environment that safeguards your valuable IT infrastructure while boosting energy efficiency. Remember, it's your raised floor's complete grounding system that delivers this exhaustive protection.

Leave a Reply