Static control equipment calibration and certification guarantee your ESD protection systems work correctly to prevent damage to sensitive electronic components. You'll need regular testing and calibration of equipment like wrist straps, ESD mats, and ionizers to meet industry standards like ANSI/ESD S20.20 and IEC 61340-5-1. This includes measuring resistance to ground, surface resistivity, and decay times using specialized test equipment. You must maintain detailed records of all calibrations, certifications, and compliance audits, typically performed annually by accredited third-party bodies. Proper understanding of these requirements will help you establish an effective ESD control program that safeguards your operations.

Understanding Static Control Equipment Basics

A well-designed static control system acts as your first line of defense against electrostatic discharge (ESD) damage in sensitive electronic environments. To establish effective static control, you'll need to understand the fundamental components and their roles in maintaining a protected workspace.

Your static control system starts with proper grounding, which serves as the primary method for controlling static charge on equipment. You'll want to implement a common point ground system that connects all grounding conductors to the same electrical potential. The equipment grounding conductor, typically the green wire in AC systems, provides the preferred path for ESD control.

Regular testing of wrist straps and other grounding devices is crucial, with daily verification recommended unless continuous monitoring systems are in place.

You'll need to outfit your workspace with ESD protective surfaces that maintain the same electrical potential as other control items while providing a path to ground for static dissipation.

Your system should include essential tools like static eliminators, ionizing equipment, and continuous monitors to regulate static levels.

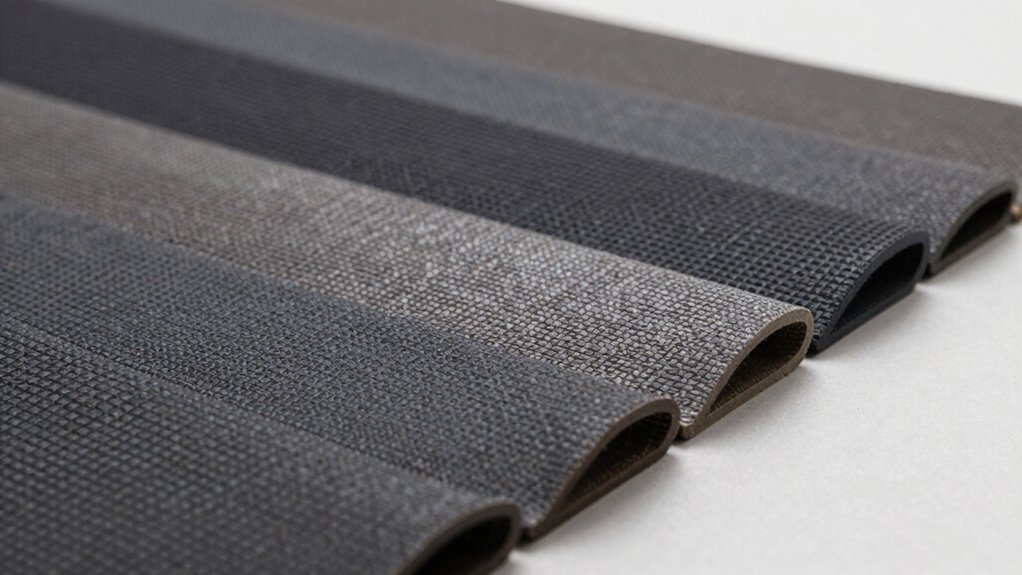

Don't forget to incorporate ESD safe products such as bags, garments, and matting to create a thorough protection system.

When designing your workstation, guarantee all surfaces and grounding devices connect to a common point ground, and use continuous monitors to verify that components maintain proper electrical potential.

Calibration Process and Methods

Once you've set up your static control system, maintaining its accuracy through proper calibration becomes the next key focus. You'll need to perform regular calibration checks at least annually, or more frequently if you've relocated equipment or installed new components.

The calibration process for static control equipment follows a systematic approach. You'll start by preparing your equipment, ensuring it's clean and in good working condition. A thorough visual inspection must be completed before starting any calibration procedures.

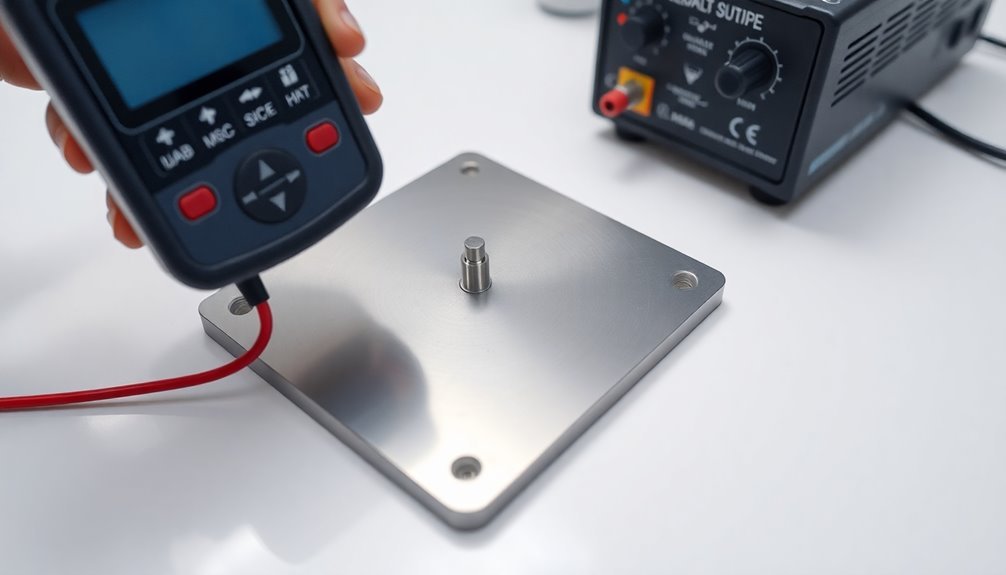

Next, you'll connect your device to a reference standard to compare measurements and identify any discrepancies. For ESD workstations, you'll need to test the surface-to-ground resistance at multiple points to verify proper grounding.

During calibration, you'll make necessary adjustments to align your equipment with the reference standard. This may involve modifying internal electronics or physical components until readings fall within specified tolerance levels.

You'll document all measurements, including before and after adjustments, for your records.

After completing adjustments, you'll verify the calibration's success through additional measurements. Maintaining traceable calibration records that demonstrate your equipment's compliance with national standards is crucial.

This documentation proves your static control system meets required specifications and operates reliably.

Certification Requirements and Standards

The certification of static control equipment follows two primary international standards: ANSI/ESD S20.20 and IEC 61340-5-1. These standards have replaced Mil-std 1686 and are now required by major companies like IBM, Lucent, and Lockheed Martin. Over 1,900 certified facilities worldwide demonstrate the growing importance of these standards. Until May 2025, you can certify to either the 2016 or 2024 version of IEC 61340-5-1.

Your facility must meet both technical and administrative requirements for certification. You'll need proper grounding systems, ionization equipment, and static-protective packaging.

Your personnel must use approved wrist straps and footwear that meet resistance specifications.

You'll also need to implement an ESD Control Program Plan that includes training, compliance verification, and document control procedures.

To maintain certification, you'll undergo annual audits by accredited third-party certification bodies. The benefits you'll gain include improved process performance, reduced component failures, and enhanced marketability.

The certification integrates well with other management systems like ISO 9001 and AS9100, giving you global recognition among international OEMs and procurement authorities.

You'll need to handle non-conforming products according to established procedures and maintain thorough documentation of your ESD control measures.

Equipment Testing Procedures

Proper certification requires rigorous testing procedures to verify your static control equipment meets established standards.

You'll need to conduct surface and volume resistance measurements using ANSI/ESD STM11.11-2015 and STM11.12-2015 standards, ensuring values remain below 1.0 x 10^11Ω.

For electrostatic decay testing, you must follow MIL-STD-3010C protocols with a maximum 2.0-second decay time. Triboelectric charge generation must be evaluated using nanocoulombmeters for accurate material contact assessment.

Your testing should utilize specialized ESD meter kits for RTT and RTG measurements on ESD mats, while static shielding tests require 1kV Human Body Model discharge evaluations at both 12% and 50% relative humidity.

You'll need to maintain precise environmental control during all tests, as humidity substantially affects results.

When testing PPE like gloves and garments, you must follow ANSI/ESD SP15.1-2011 guidelines for resistance measurements and conduct charge decay tests after 48 hours of preconditioning at 12% RH.

Your test reports should document peak current and energy measurements across 12 samples at specified humidity levels.

All testing must comply with ANSI/ESD S541-2008 and S20.20-2014 safety standards using appropriate test fixtures and equipment.

ESD Workstation Setup Essentials

Setting up an effective ESD workstation requires five critical components working in harmony: a properly grounded table mat, floor mat, wrist strap system, common point ground, and appropriate testing equipment.

You'll need to start by installing the ESD table mat flat on your workbench, making certain the snap connectors face toward you. Sunlight exposure can help flatten any curled mats. Connect your common point ground cord to the mat using the grounding snap, then attach your wrist strap to the coil cord and connect it to the same common point ground.

Place your ESD floor mat in front of the workbench with the snaps facing up, and ground it properly.

Don't forget to verify all grounding connections using a surface resistivity meter. You'll need to test the continuity from the ground point to each component of your workstation.

Remove any non-ESD materials from your work area or replace them with ESD-protective versions. If you can't remove certain insulators, install an air ionizer to neutralize static buildup.

Remember to regularly test your wrist straps and heel grounders to make certain they're functioning correctly.

Your entire workstation should connect to a common ground point, typically using a green wire building ground as specified in EOS/ESD Standard 6.

Maintaining Compliance and Documentation

You'll need to establish robust record-keeping practices that include proper storage of calibration certificates, equipment logs, and maintenance records.

Testing and certification processes must ensure your flooring maintains resistance below 10^9 ohms to meet industry standards.

Your annual audits should track all ESD control elements, verify calibration dates, and check compliance with ANSI/ESD S20.20 and IEC 61340-5-1 standards.

Managing your calibration certificates requires a systematic approach where you'll maintain digital and physical copies, track expiration dates, and guarantee all documentation meets ISO 17025 requirements.

Record Keeping Best Practices

Meticulous record keeping forms the backbone of effective static control equipment management. You'll need to maintain thorough records that track calibration activities, certifications, and equipment performance over time. Records must be kept for a minimum of 2 years to meet regulatory requirements.

To guarantee accuracy and reliability, implement a standardized electronic record-keeping system that includes robust security measures and automatic backup capabilities.

When organizing your calibration records, create a systematic approach that captures essential data points like equipment identification, calibration dates, technician information, and test results. You'll want to design user-friendly templates that make it easy for your team to input and retrieve information while maintaining data integrity.

Guarantee your system includes audit trails to track any changes made to records.

Your maintenance logs should clearly define the scope of equipment being monitored and include detailed fields for maintenance activities, personnel assignments, and verification steps.

Don't forget to establish specific retention periods for different types of records and implement power protection systems to prevent data loss.

Regular reviews of your record-keeping practices will help you identify areas for improvement and maintain compliance with industry standards.

Remember to train your staff thoroughly on proper documentation procedures to guarantee consistency across all records.

Annual Audit Requirements

Through thorough annual audits, you'll maintain compliance with ESD control standards while protecting sensitive electronic components.

You'll need to conduct regular audits, often monthly, using sampling techniques and statistical analysis to verify that your ESD control equipment and protective materials function within required limits.

Your audit process must follow standards like ANSI/ESD S20.20 and IEC 61340-5-1, using detailed checklists to guarantee consistent coverage of all program components. Regular employee training sessions are essential for maintaining awareness of proper ESD safety protocols.

You'll need to test personnel, equipment, and procedures using specialized test equipment appropriate for each measurement. When you find discrepancies, document them and report them to supervisors with corrective recommendations.

To maintain effective compliance verification, you'll want to implement a testing schedule that includes daily checks of wrist straps and weekly workstation inspections.

You must guarantee all your test equipment has current calibration certificates and meets industry standards. It's best to assign a single auditor to maintain consistency in performing these evaluations over time.

Remember to analyze your audit results statistically to identify significant changes and trends that require attention.

Calibration Certificate Management

Proper calibration certificate management builds upon your audit program by providing documented proof of equipment accuracy and reliability. You'll need to maintain detailed certificates that include essential elements like lab details, customer information, unique identification codes, and environmental conditions during testing.

Each certificate must contain a clear traceability statement and the tester's signature.

To stay compliant, you'll want to establish a robust management system that includes regular scheduling of calibrations, inventory tracking, and documentation of pre and post-calibration inspections. It's critical to follow UKAS format requirements for accredited certificates and maintain an unbroken chain of traceability to national standards like NIST.

Request sample certificates from your calibration partners to verify they meet your audit requirements.

Implement an electronic documentation system with version control to streamline your process. You should regularly train your staff on calibration procedures and maintain records of technician qualifications.

Don't forget to include certificate expiry dates and document any corrective actions taken for non-conformances. Regular audits of your calibration management system will help identify areas for improvement and maintain compliance with ISO standards.

Frequently Asked Questions

How Often Should ESD Wrist Straps Be Replaced for Optimal Safety?

You should replace your ESD wrist straps when they fail daily testing or show signs of wear. Don't wait for a specific timeframe – regular testing and maintenance will indicate when replacement's necessary for maximum safety.

What Humidity Levels Are Ideal for Static Control Equipment Operation?

You'll want to maintain relative humidity between 30% and 70% for ideal static control equipment operation. Aim for around 50% RH if possible, but be careful not to exceed 70% to avoid corrosion issues.

Can Static Control Equipment Be Calibrated In-House Instead of Externally?

While you can calibrate static control equipment in-house, it's challenging due to specialized knowledge requirements and limited access to standards. You'll face difficulties maintaining traceability and meeting regulatory compliance without external expertise.

How Do Temperature Fluctuations Affect Static Control Equipment Accuracy?

Temperature fluctuations will affect your static control equipment's accuracy by causing dimensional changes, shifting electronic properties, and altering mechanical calibrations. You'll notice measurement errors if you don't maintain a temperature-controlled environment.

What Insurance Coverage Is Recommended for Certified Static Control Equipment Facilities?

You'll need thorough property insurance with ESD-specific coverage, boiler and machinery coverage up to $2 million, liability insurance for static-related incidents, and contractor insurance when outsourcing static control work in your facility.

In Summary

You'll need to maintain regular calibration and certification of your static control equipment to guarantee workplace safety and compliance with ESD standards. Stay current with your testing schedules, keep detailed documentation of all calibrations, and verify that your workstations meet certification requirements. By following these protocols, you're protecting sensitive components and maintaining the reliability of your static control measures.

Leave a Reply