You'll need three key elements to organize a static-safe workbench effectively. Start by establishing proper grounding points through an anti-static mat connected to a centralized system with copper wiring and personal grounding equipment like wrist straps. Next, implement modular storage solutions using ESD-safe cabinets and adjustable shelving to maximize both horizontal and vertical space. Finally, create dedicated tool organization zones with magnetic strips, shadow boards, and properly labeled containers for quick access and inventory management. These foundational steps will set you up for a more detailed approach to static-safe workspace optimization.

Maximize Your Grounding Points

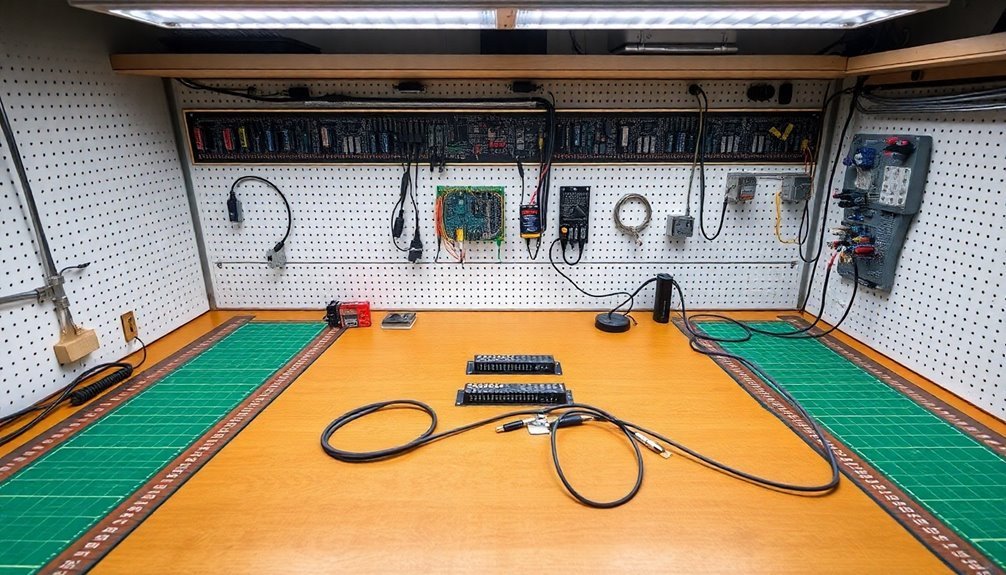

When setting up your workbench's grounding system, you'll need to incorporate multiple essential components to guarantee complete ESD protection.

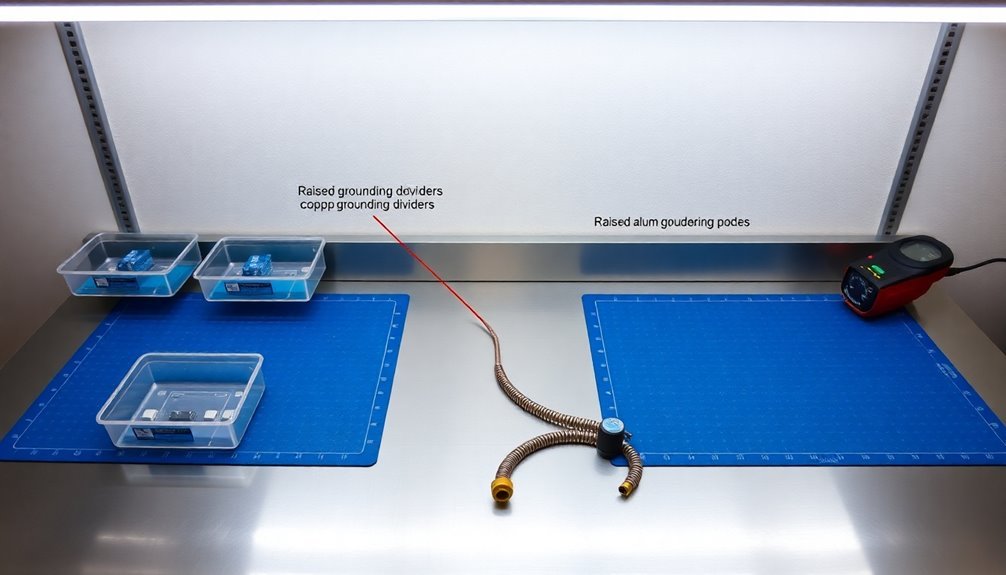

Start by installing an anti-static workbench mat connected to a grounding cord through properly fitted metallic snaps or crimps. Make sure you're using the correct resistance values – your mat should measure between 10^6 to 10^9 Ω from any point to the ground wire system.

Connect your grounding points to a centralized location using multi-strand copper wire with at least a 2mm cross-section. ESD-safe tools should be kept within easy reach to maintain static protection throughout your work session.

Don't forget to incorporate personal grounding equipment – you'll need a wrist strap for yourself and foot grounders if you're moving around the workspace. Install conductive floor mats beneath your chair to maintain continuous grounding while you work.

Test your setup regularly using a ground/polarity tester to verify proper wiring and charge dissipation.

Remember to connect all external equipment, including test instruments and power supplies, to your grounding system.

For maximum safety, implement soft grounding by connecting your mats in series with 1MΩ resistors. Keep your system's total resistance under 1Ω to confirm effective static discharge prevention.

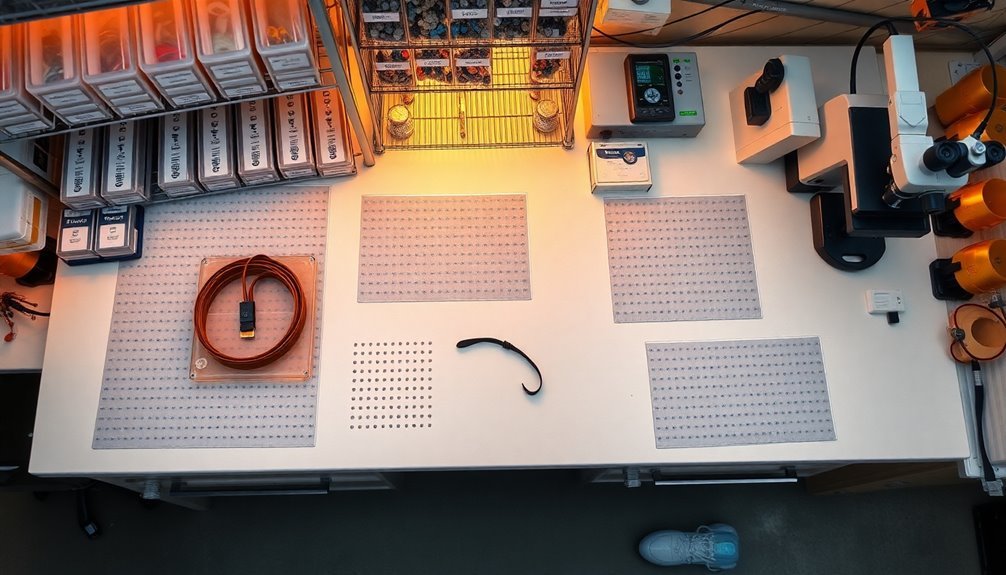

Modular Storage Solutions

Every efficient workbench needs a well-planned modular storage system to maximize productivity and organization. You'll want to incorporate adjustable storage options that can accommodate different types of tools and equipment while maintaining static-safe conditions through proper grounding and ESD-protective components. Fully welded workstation components provide superior durability and stability for your storage solutions.

Start by implementing StaticGard cabinets and ESD-safe storage solutions to protect sensitive equipment from static damage. You can customize your storage configuration with drawers, shelves, and pegboards that suit your specific workflow needs.

Make the most of vertical space by installing adjustable shelving units above your workbench, ensuring all commonly used items remain within easy reach.

Don't forget to establish a clear labeling system for your storage components. This will help you quickly locate tools and maintain organization throughout your workspace.

Consider adding point-of-use gravity-fed conveyors to streamline your workflow and reduce unnecessary movement. You can also integrate modular accessories that can be easily added or removed as your storage needs change.

Remember to keep your storage solutions flexible and adaptable. Using interchangeable components allows you to modify your setup as your work requirements evolve, ensuring long-term efficiency in your static-safe workspace.

Tool Organization Zones

Make use of magnetic tool strips for quick access to metal tools, and implement shadow boards to instantly identify missing items.

You can organize smaller components using drawer dividers and stackable containers. Creating clear labels on each container helps maintain long-term organization.

Don't forget to utilize overhead cabinets and wall-mounted toolboxes for additional storage options.

For portable needs, incorporate toolboxes and chests that complement your static storage system.

Remember to position tools based on frequency of use, keeping your most-used items within arm's reach of your primary work area.

Frequently Asked Questions

How Often Should ESD Wrist Straps Be Tested for Proper Functionality?

You'll need to test your ESD wrist strap daily when it's used every day. If you're handling highly sensitive components, you can opt for continuous monitoring systems that provide real-time testing and alerts.

What Humidity Levels Are Optimal for Maintaining a Static-Safe Environment?

You'll want to maintain relative humidity between 40-60% for ideal static safety. If you can't reach this range, keep it above 30% minimum, as levels below 20% create dangerous static buildup.

Can Regular Cleaning Products Be Used on Esd-Safe Workbench Surfaces?

No, you shouldn't use regular cleaning products on ESD surfaces. They'll damage static-dissipative properties and leave residues that attract static. Always use specialized ESD-safe cleaners to maintain your workbench's protective qualities.

When Should Ionizers Be Replaced in a Static-Safe Workspace?

You'll need to replace ionizers when they fail offset voltage specs, can't meet discharge time limits, have uncleanlable contamination, show physical damage, or don't perform well despite maintenance. Follow manufacturer's replacement guidelines.

Are Metal Storage Containers Automatically Considered Static-Safe for Electronic Components?

No, you can't assume metal containers are static-safe. They're actually conductive and can cause rapid discharge. You'll need containers specifically designed with proper surface resistivity (10^6 to 10^9 ohms/square) for safe ESD protection.

In Summary

You'll find that investing time in organizing your static-safe workbench pays off through increased efficiency and better ESD protection. Set up multiple grounding points strategically, implement modular storage that grows with your needs, and create dedicated zones for your tools. When you've got these three elements working together, you're ready to tackle any electronics project safely and systematically.

Leave a Reply