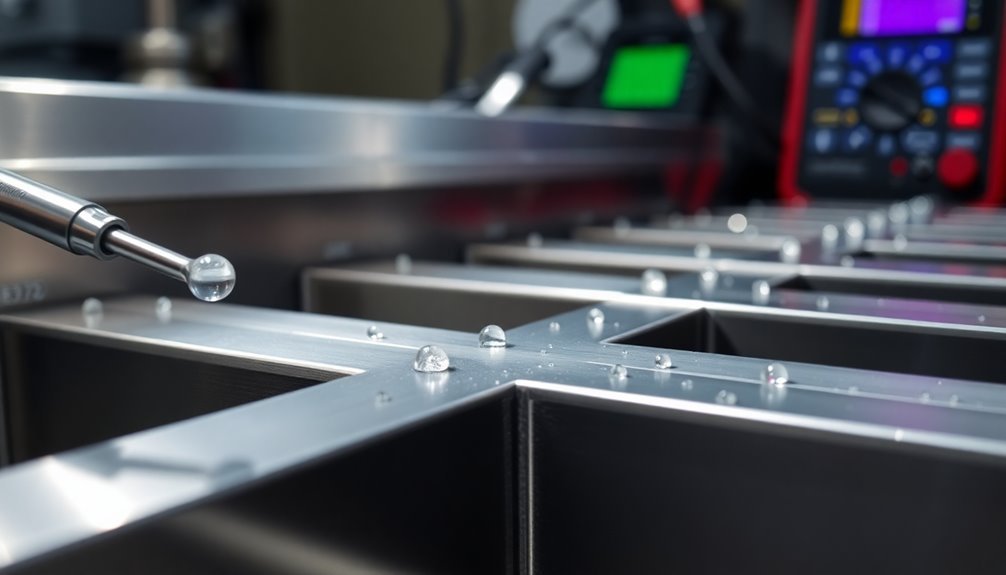

When measuring static runner electrical resistance, you'll want to follow three key tips for accuracy. First, always use the relative mode on your meter to subtract test lead resistance interference from your measurements. Second, maintain a precise 100mm distance when taking surface voltage measurements to guarantee proper calibration and consistent results. Third, isolate individual components during testing since parallel paths can reduce total circuit resistance and skew your readings. Understanding these fundamentals of resistance testing will help you achieve more reliable measurements, with plenty more technical insights to explore in the field of runner performance analysis.

Measuring Static Runner Performance

Remember that test lead resistance can affect your measurements, so use the relative mode (zero or Delta mode) to subtract this interference.

Surface voltage measurements should be taken at exactly 100mm distance for proper calibration and accuracy. Qualification meters deliver superior accuracy compared to verification meters for precise resistance testing. Watch out for parallel paths that might lower total circuit resistance – always isolate components during testing. Your meter should display readings either in Ohms or on a decade scale, often with color-coded LEDs for quick classification.

Temperature and humidity can impact your results, so choose a meter that can handle environmental variations.

Voltage Safety Rating Standards

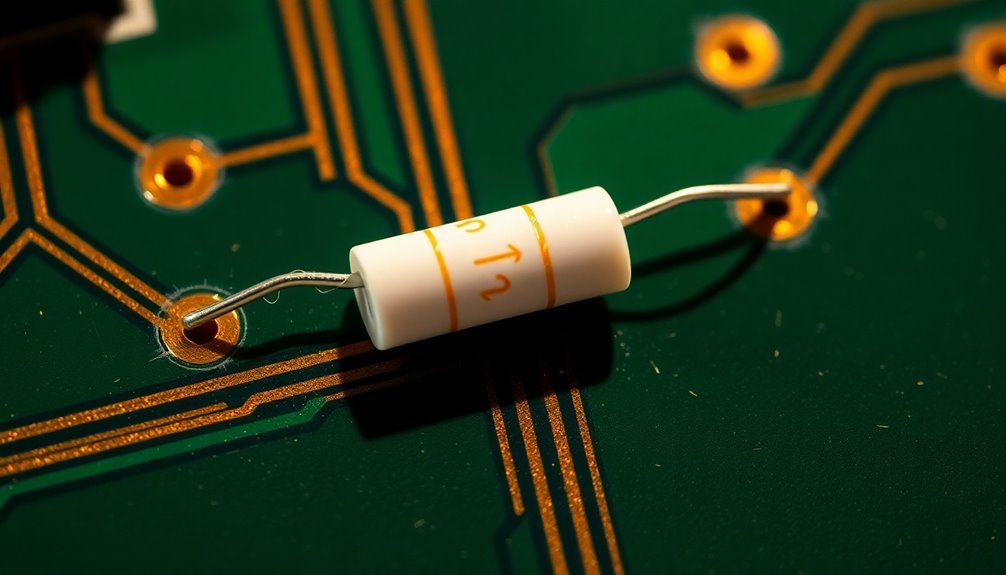

When working with static runners, understanding voltage safety ratings becomes a natural extension of proper measurement practices. You'll need to know that voltages above 50V are considered hazardous touch voltage, with DC current above 25mA at 50V and AC current above 10mA at 120V posing significant risks under normal conditions.

For your static runner testing, you'll want to make certain your test equipment meets proper safety standards. Your equipment must carry the appropriate CAT rating for your working environment – CAT II for single-phase loads, CAT III for three-phase distribution, or CAT IV for utility connections. Class 2 circuits provide an additional safety margin with maximum limits of 30V rms or 42.4V peak. According to NFPA 70E standards, workplace electrical safety must be prioritized during all testing procedures.

Make sure your instruments are certified by an independent testing agency and clearly labeled with their Measurement Category rating.

If you're working with low voltage applications (1,000V or less), follow SELV circuit guidelines that limit voltages to 42.4V peak AC or 60V DC.

You'll need to pay special attention to both voltage and current levels, as both factors contribute to potential hazards. Remember that proper test equipment selection isn't just about accuracy – it's vital for preventing electrical accidents and guaranteeing your safety during measurements.

Runner Resistance Testing Methods

Through proper assessment procedures, runners can effectively measure their resistance levels using several standardized testing methods. You'll find that each test serves a specific purpose in evaluating different aspects of runner performance and capacity. Regular testing provides reliable data for tracking absolute VO2max levels through systematic measurement. The Weight-Bearing Lunge Test provides an excellent way to evaluate ankle flexibility and strength in runners.

| Test Type | Key Features |

|---|---|

| Cooper Test | 12-minute duration; measures maximum distance for aerobic fitness |

| RAST | 6 sprints with 10-second recovery; evaluates anaerobic power |

| Single Leg Balance | 30-second max duration; assesses hip stability and balance |

| Shuttle Run | Progressive speed increases; measures VO2max and endurance |

For aerobic assessment, you'll want to use the Cooper Test, which gives you 12 minutes to cover as much distance as possible. When testing anaerobic capacity, the RAST protocol requires you to perform six maximal sprints over 35 meters with brief recovery periods. To evaluate musculoskeletal stability, you can perform the Single Leg Balance Test, standing on one leg for up to 30 seconds. The Shuttle Run Test challenges your neuromuscular endurance by having you run between markers at increasingly faster speeds until exhaustion.

Frequently Asked Questions

Can Static Runners Be Safely Worn in Wet Conditions?

You shouldn't wear static runners in wet conditions, as moisture considerably reduces their electrical resistance. If you need footwear for wet environments, you'll want to choose conductive shoes specifically designed for those conditions.

How Often Should Static Runners Be Replaced to Maintain Protective Properties?

You'll need to inspect your static runners regularly, replacing them when you notice signs of wear or reduced performance. While there's no fixed timeline, conduct monthly checks to maintain protective properties effectively.

Do Static Runners Require Special Cleaning Methods to Preserve Their Resistance?

Yes, you'll need to use soft, dry cloths and specialized static control cleaners. Don't use strong chemicals or water, as they can damage electrical properties. Always test resistance after cleaning to ascertain effectiveness.

What Temperature Ranges Affect Static Runner Performance?

You'll notice static runners work best between 15-25°C (59-77°F). At higher temperatures, they'll become less effective due to increased resistance, while extreme cold can make them too conductive for safe static control.

Can Static Runners Be Modified With Aftermarket Insoles Without Compromising Protection?

You can safely use aftermarket insoles in static runners if they're ESD-certified. Just verify the insoles don't disrupt the shoe's grounding properties and maintain proper contact between your foot and the conductive elements.

In Summary

You'll find that proper testing and measurement of your static runners' electrical resistance is vital for safety and performance. By following standardized voltage ratings and regularly conducting resistance tests, you can guarantee ideal functionality. Remember to document your test results and maintain consistent testing schedules. Don't skip these essential steps – they'll help prevent equipment failures and workplace hazards.

Leave a Reply