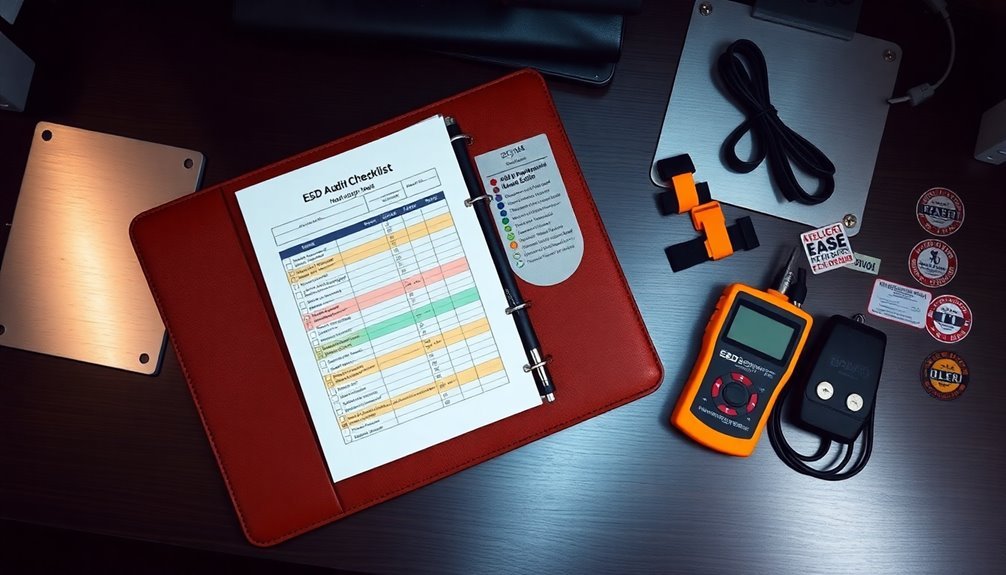

The best ESD audit report templates prioritize thorough documentation while maintaining clarity and efficiency. You'll benefit from using basic static control checklists, equipment verification formats, and safety compliance documents to monitor your facility's ESD protection. Key templates include environmental monitoring reports, risk assessment matrices, quality control sheets, and corrective action plans – all designed to meet ANSI/ESD S20.20 standards. Manufacturing floor assessments and personnel training audit forms round out your documentation needs. These templates not only guarantee regulatory compliance but also streamline your audit process, with each format offering specific advantages for different aspects of ESD control.

Basic ESD Audit Template

Three key components form the foundation of a basic ESD audit template: the audit scope, content categories, and reporting structure. Your audit scope should clearly define objectives, specify ESD control procedures, and align with regulatory requirements while maintaining specific boundaries of what's included and excluded.

For content categories, you'll need extensive checklists covering program management, quality processes, and ESD Control Program compliance. These checklists should address management oversight, training protocols, engineering controls, procurement practices, and work area specifications. Regular feedback to employees and management helps reinforce the program's importance and effectiveness.

You'll also need to incorporate both visual and electrical testing procedures for ESD control equipment.

When it comes to reporting, you'll document all discrepancies discovered during the audit and provide targeted recommendations for improvement. Your reports must include clear descriptions of observations, supporting evidence, and potential impacts on operations.

To maintain consistency and thoroughness, you'll need to use specialized test equipment and follow specific testing intervals for ESD control products. It's crucial to implement regular auditing schedules and utilize statistical analysis tools, such as trend and Pareto charts, to identify recurring issues and track improvements over time.

Comprehensive Static Control Checklist

Building upon the basic audit template structure, a thorough static control checklist serves as your detailed roadmap for conducting thorough ESD audits.

You'll need to verify multiple elements including personnel practices, equipment functionality, and protective material conditions through regular testing and inspection schedules. Similar to aviation safety inspections, unannounced spot checks can help ensure continuous compliance.

Your detailed checklist should cover daily wrist strap checks, weekly workstation inspections, and monthly assessments of designated ESD-protected areas.

Include quarterly resistance-to-ground testing and semi-annual ionizer balance verification to maintain complete protection.

Don't forget to examine administrative requirements like proper use of ESD smocks, safety glasses, and verified footwear.

Make sure you're documenting key inspection points such as static dissipative surfaces on workstations, proper grounding connections, and ESD caution symbol placement on assemblies.

Your checklist must address packaging requirements for material movement within protected areas.

When completing the audit report, you'll want to clearly document the scope, applicable standards, site description, and all findings – including strengths, observations, and any non-conformances.

Remember to provide specific corrective recommendations for any identified issues to improve your ESD control program's effectiveness.

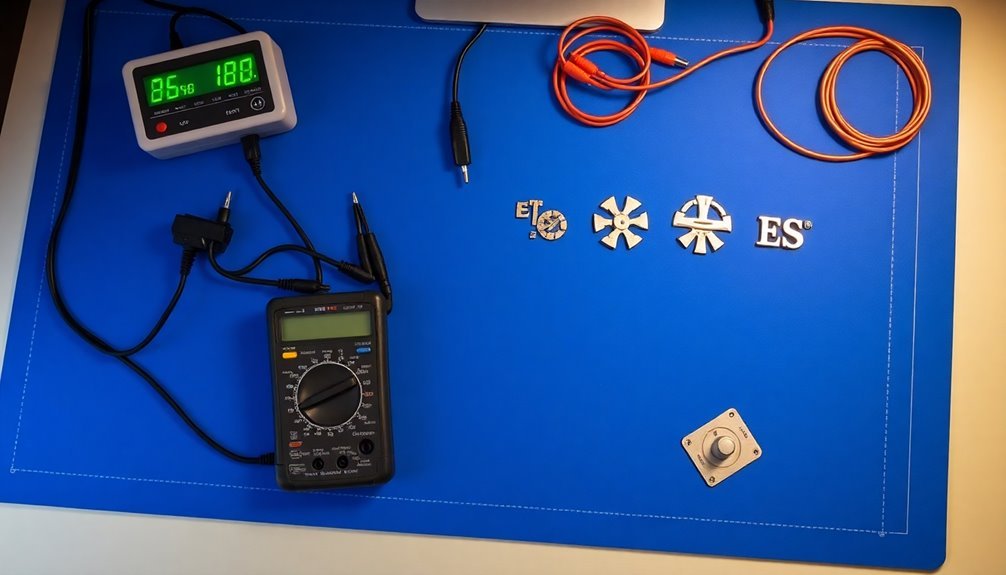

Equipment Verification Report Format

A well-structured equipment verification report serves as your cornerstone document for tracking and validating all ESD control items within protected areas.

Regular surface resistance testing must be conducted according to established compliance verification plans to maintain proper ESD protection.

You'll need to create a thorough checklist that includes every ESD control product, from worksurfaces to personnel grounding devices, guaranteeing you're meeting ANSI/ESD S20.20 standards.

You should clearly outline your verification schedule and procedures, detailing how often you'll check each item and what methods you'll use.

Train your team to properly use measurement equipment and document these procedures in your ESD Control Program Plan.

Make sure you're including both visual inspections and technical measurements.

Define specific measurement limits for each piece of equipment, following industry standards while adapting them to your company's requirements.

You'll want to incorporate guidelines for using AC Outlet Analyzers and field meters to verify grounding and ESD-safe materials.

When documenting audit findings, categorize your observations clearly and provide actionable recommendations.

Focus on process improvements rather than individual performance, and guarantee each finding links directly to specific evidence.

Your recommendations should align with regulatory requirements while remaining practical for implementation.

Safety Compliance Documentation Template

Safety compliance documentation demands a systematic approach that builds upon your equipment verification practices. You'll need to structure your documentation template to guarantee thorough coverage of all essential ESD safety elements while maintaining clear traceability of findings and actions. The reporting process typically includes filled checklists and notes from assessors to support findings.

| Component | Key Requirements | Documentation Needs |

|---|---|---|

| Scope Definition | Industry standards, audit areas | Process maps, equipment lists |

| Audit Findings | Non-conformities, control effectiveness | Classification charts, photos |

| Report Structure | Assessment criteria, site details | Checklists, performance data |

| Follow-up Actions | Corrective measures, verification | Progress tracking sheets |

Your template should clearly outline the scope and objectives of your ESD audit, including specific areas and processes you'll evaluate. You'll want to document all findings systematically, categorizing non-conformities by severity and providing detailed recommendations for improvement. Make sure you're incorporating thorough checklists and assessment notes within your report structure, along with relevant performance metrics and trend analysis. Don't forget to establish a robust follow-up mechanism that tracks the implementation of corrective actions and maintains detailed records of all audit activities and certifications achieved.

Manufacturing Floor Assessment Guide

Clean rooms and production areas demand rigorous ESD control assessment protocols to protect sensitive electronic components. When you're evaluating your manufacturing floor, you'll need to reflect on both the physical space and operational requirements to maintain proper ESD protection standards.

- Assess foot traffic patterns and environmental conditions to determine ideal flooring materials and maintenance schedules.

- Verify ESD control measures through regular testing and documentation of resistance readings.

- Monitor personnel compliance with ESD protective equipment requirements and training protocols.

Your manufacturing floor assessment should focus on identifying potential ESD hazards and implementing effective control measures. Start by examining your facility's specific industry requirements and ensuring your ESD flooring meets these standards. FDA approved flooring is essential for maintaining regulatory compliance and product integrity in sensitive manufacturing environments.

You'll want to document environmental conditions, including humidity levels and temperature fluctuations, as these factors can greatly impact ESD control effectiveness.

Don't forget to evaluate your current ESD control program's documentation, including training records and audit procedures. Regular inspections and measurements are essential – they'll help you verify that your ESD protection measures remain effective over time.

Remember to maintain detailed records of all assessments and immediately address any deviations from established standards.

Personnel Training Audit Form

Through thorough documentation, personnel training audit forms serve as essential tools for maintaining ESD compliance standards in your facility.

You'll need to create a detailed form that tracks whether your staff's training aligns with ANSI/ESD S20.20 standards and captures all essential training elements. Training needs analysis helps identify specific areas where additional ESD control instruction may be required.

Your audit form should include sections to verify training content coverage, documentation of completion dates, and assessment scores. Include checkboxes to confirm that employees have received instruction on specific ESD control measures and understand proper handling procedures for sensitive components.

You'll want to incorporate fields for tracking refresher training schedules and verifying that retraining occurs within the required 24-month timeframe.

Make certain your form provides space to document non-conformities and their severity levels. Include sections for evaluating training materials' relevance and compliance with current standards.

Add fields to assess the effectiveness of training methods, including written tests and practical demonstrations. Don't forget to include spaces for corrective action recommendations and follow-up dates.

Your form should conclude with signature fields for both the auditor and department supervisor to guarantee accountability and tracking.

Environmental Monitoring Report Structure

When establishing an effective environmental monitoring report structure, you'll need a standardized format that captures all critical ESD control parameters in your facility. Your report structure should follow specific guidelines for consistency and clarity, ensuring all essential components are properly documented and easily accessible to stakeholders.

- All printed reports must be double-sided on 8.5" x 11" paper, with larger maps (up to 11" x 17") permitted when necessary for clarity.

- Data units must be specified throughout figures, tables, and text, including the number of data points for statistical measurements.

- Document footers should contain standardized information like document type, project details, page numbers, and version control.

Start your report with an all-encompassing project summary that includes the setting, background, and pre-construction conditions.

You'll need to incorporate specific data templates for presenting project quantities, credits, and current condition plan views.

Don't forget to outline performance criteria and project attributes in tabular format.

Include relevant appendices containing hydrologic data, verification of bankfull events, and monthly rainfall summaries.

Remember to maintain a master folder for all electronic files using proper naming conventions for easy access and organization.

Risk Assessment Matrix Template

You'll find that an effective ESD risk assessment matrix combines a severity versus likelihood scale, typically using a 5×5 grid to evaluate potential static discharge threats.

Regular risk matrix updates ensure your ESD assessment stays relevant as workplace conditions and technologies evolve.

Your control measures' priority levels should align with the risk scores, ensuring immediate action for high-risk areas (red zones) while maintaining regular monitoring for lower-risk categories.

The risk level categories, usually color-coded as red (high), yellow (medium), and green (low), help you quickly identify where to focus your ESD protection efforts and allocate resources accordingly.

Severity Vs Likelihood Scale

A robust risk assessment matrix combines two vital components: severity and likelihood scales. When creating your ESD audit report, you'll need to understand how these scales work together to effectively evaluate and prioritize potential risks in your facility.

- Severity scales measure the potential impact of ESD events, ranging from minor equipment damage to catastrophic production line failures.

- Likelihood scales assess the probability of ESD incidents occurring, based on historical data and current control measures.

- Both scales can use either 3-point or 5-point systems, with 5-point offering more detailed risk categorization.

You'll want to start by defining your severity criteria, considering factors like equipment damage costs, production downtime, and recovery difficulty. Regular attention and iteration is crucial for maintaining an accurate risk assessment as threats evolve over time.

For likelihood assessment, focus on your facility's ESD history, control measure effectiveness, and environmental conditions.

When you've established both scales, you can plot them on your matrix using color coding for visual clarity. This intersection creates risk zones that'll help you prioritize your ESD control measures.

Remember that a 5×5 matrix provides more granular risk assessment than a 3×3, which might be essential for sensitive electronics manufacturing environments.

Control Measures Priority

Through the lens of ESD risk management, creating a structured risk assessment matrix template is essential for prioritizing your control measures effectively.

You'll need to base your control measures on both risk assessment findings and audit results, guaranteeing that you're addressing the most critical issues first.

Start by implementing a 5×5 matrix structure to classify risks into high, medium, and low categories.

You'll want to evaluate each risk based on its likelihood and severity scores, which will help you determine the impact level.

When you encounter risks with identical scores, conduct further assessment to establish their relative priority.

Your control measures should directly correspond to audit findings, which will provide you with a detailed list of deviations and suggested priorities.

Focus on process inspection to assess specific ESD risks in your production operations.

You'll need to verify compliance through regular audits using specialized test equipment like resistance testers and electrostatic fieldmeters.

Remember to document all findings in your audit reports and maintain records of corrective actions taken.

This systematic approach guarantees you're addressing ESD risks methodically while maintaining compliance with program procedures and standards.

Risk Level Categories

Building on the foundation of control measure prioritization, risk level categories form the backbone of your ESD risk evaluation matrix template. You'll need to construct your template using Excel with specific features that enable quick and accurate risk appraisal while maintaining compliance with industry standards.

- Color-coded severity levels that instantly highlight critical ESD risks requiring immediate attention

- Drop-down menus for consistent risk categorization across different audit scenarios

- Automated rating calculations that factor in both severity and likelihood of ESD events

When developing your risk level categories, focus on incorporating classification criteria that address the severity of potential ESD damage, compliance requirements, and existing control effectiveness.

You'll want to structure your template to evaluate each process step systematically, starting with severe or critical risks that could impact operations and safety.

Remember to include fields for appraising personnel training levels and protective equipment effectiveness, as these directly influence risk severity ratings. Your template should enable quick identification of non-compliant areas and track the implementation of corrective actions.

Make sure each risk category clearly defines the required response time and necessary mitigation steps to maintain audit efficiency.

Quality Control Verification Sheet

Your quality control verification sheet must include specific equipment testing standards that align with industry-approved ESD control protocols.

You'll need to document daily measurements of critical parameters, including surface resistivity, grounding systems, and ionizer performance.

The data you collect should be time-stamped and organized to track trends and identify potential compliance issues before they become serious problems.

Equipment Testing Standards

Equipment testing standards form the backbone of a robust ESD control program, requiring specific test equipment and precise measurement capabilities.

You'll need to guarantee your testing equipment meets EPA compliance verification requirements and can perform measurements with the precision defined in your verification plan.

- Regular compliance audits with statistical analysis to track ESD control effectiveness

- Detailed checklists and documentation for consistent equipment testing

- Specific procedures for handling non-compliance situations

When implementing your testing standards, you'll want to focus on key components including product qualification, grounding verification, and equipotential bonding systems.

Your verification plan must include an extensive list of ESD items within the EPA that require regular checking, along with specific schedules and test procedures that align with ANSI/ESD S20.20 and ESD TR53 guidelines.

Documentation is essential – you'll need to maintain detailed records of all compliance verification activities.

Your audit reports should clearly outline the scope, standards being assessed, and any findings.

Remember to categorize and promptly address any non-compliance issues, making sure they're reported to management for immediate action.

This systematic approach helps maintain the integrity of your ESD control program.

Daily Measurement Documentation

Proper documentation of daily ESD measurements forms the foundation of an effective quality control program. You'll need to establish a structured verification plan that includes specific daily checks, particularly in high-risk ESD areas. Your documentation should capture both visual and electrical test results, using standardized checklists to maintain consistency across all audits.

When setting up your daily measurement system, you'll want to create detailed records that track trends and provide evidence of conformity to technical requirements. Your verification plan must list all ESD control products requiring regular checks, along with their testing schedules and methods.

Make sure you're following ANSI/ESD S20.20 standards, or document justification for any alternative testing procedures you're using. You'll need to maintain thorough compliance verification records and implement corrective actions whenever deficiencies emerge.

Your measurement equipment must match the specifications outlined in your compliance verification plan. By analyzing trends in your daily measurements, you can identify potential issues before they become problems.

Corrective Action Planning Template

A well-structured corrective action planning template serves as the backbone for addressing ESD audit findings and implementing necessary improvements. You'll need a template that clearly outlines the scope, responsibilities, and timelines for addressing non-conformities identified during ESD audits.

- Customizable sections for documenting specific ESD control deviations and their potential impacts

- Built-in prioritization matrix to classify and address issues based on severity levels

- Integrated tracking mechanisms for monitoring implementation progress and verification steps

When designing your corrective action planning template, include spaces for defining the problem, assigning responsibility, and establishing implementation schedules.

You'll want to incorporate root cause analysis sections and clear documentation protocols to guarantee thorough problem resolution. Be certain your template features visual elements like charts or timelines to illustrate the corrective action process effectively.

Your template should also include verification checkpoints and follow-up audit schedules. It's crucial to maintain flexibility in your template design, allowing for updates based on emerging industry standards and organizational needs.

Remember to include sections for compliance verification records and regular ESD control product checks to maintain sustained conformity with ESD requirements.

Frequently Asked Questions

How Often Should Internal ESD Audits Be Conducted Between Official Certification Audits?

You should conduct internal ESD audits monthly, but you can adjust frequency based on your facility's risk level and past performance. At minimum, perform quarterly checks between annual certification audits to maintain compliance.

What Qualifications Should ESD Auditors Possess to Maintain Report Credibility?

You'll need ESD Auditor certification, thorough knowledge of ANSI/ESD S20.20 standards, proven auditing experience, and strong analytical skills. Don't forget to maintain continuous education and stay current with industry updates.

Can ESD Audit Templates Be Customized for Different Industry-Specific Requirements?

Yes, you can customize ESD audit templates for your industry's unique needs. They'll help you meet specific requirements, whether you're in electronics manufacturing, healthcare, aerospace, or automotive sectors, while ensuring proper compliance.

How Long Should Completed ESD Audit Reports Be Retained for Compliance?

You should retain your ESD audit reports for at least 3 years to meet common industry standards, though you'll want to keep them for 6-7 years if you're subject to HIPAA or SOX regulations.

Should Suppliers Undergo the Same ESD Audit Process as Internal Facilities?

Yes, you'll want your suppliers to follow equivalent ESD audit processes as your internal facilities to maintain consistent quality standards, though you can adjust frequency and depth based on their specific risk levels and performance.

In Summary

Using these essential ESD audit report templates, you'll streamline your compliance process and maintain consistent documentation standards. You can now confidently track static control measures, verify equipment performance, and implement corrective actions when needed. Don't hesitate to customize these templates to fit your facility's specific requirements while ensuring you're meeting all necessary ESD protection standards and regulatory guidelines.

Leave a Reply