For ideal lab ESD protection, you'll find five standout anti-static workbench options. Premium Stainless Steel ESD Tables offer robust construction with integrated grounding and height adjustability. Industrial Grade Static Control Benches feature welded steel frames and meet ANSI/ESD standards. Modular Anti-Static Workstations provide customizable configurations with quick assembly options. Heavy-Duty Laboratory ESD Surfaces resist chemicals with phenolic resin construction and reliable static dissipation. Compact ESD-Safe Technical Benches maximize space while maintaining high resistance dissipative surfaces. Each option brings unique advantages to your lab environment, and understanding their specific features will help you make the best choice for your needs.

Premium Stainless Steel ESD Tables

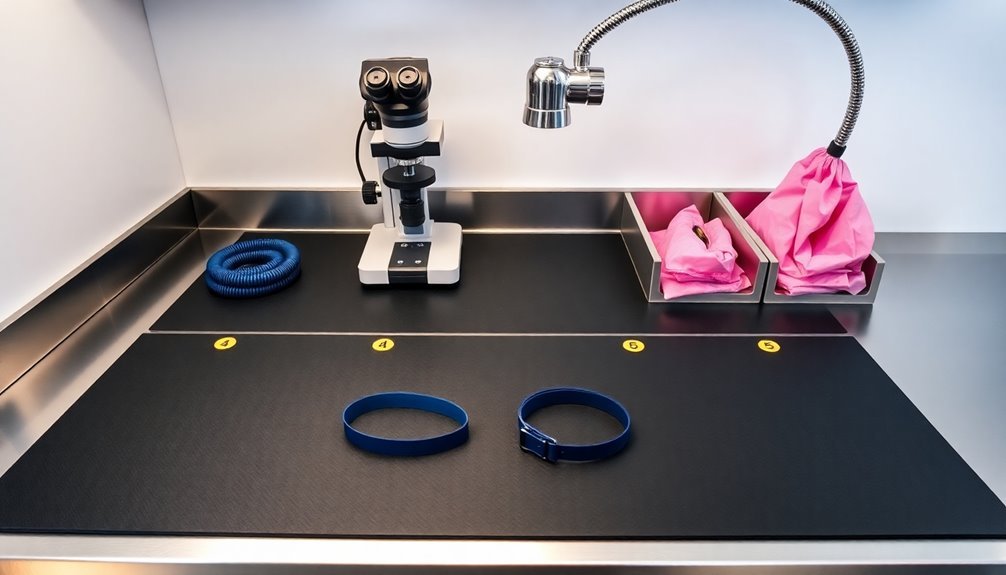

Premium stainless steel ESD tables stand out as the gold standard for anti-static workbenches in laboratory environments. They are built with robust stainless steel frames and tops that deliver maximum durability while incorporating essential static dissipative surfaces. The undersides feature aluminum sheet lamination for superior conductivity across the entire work surface.

They're designed to meet strict industry standards, including IEC 61340-5-1 and ANSI/ESD S20.20, ensuring reliable ESD protection for your sensitive equipment.

When you're selecting a premium ESD table, you'll notice features like hydraulic or crank adjustable heights for ergonomic comfort and impressive weight capacities up to 5,000 pounds. The integrated grounding systems come with convenient wrist strap plugs and grounding points, making it easy to maintain a static-safe workspace.

Leading manufacturers like Bench Depot and Treston offer customizable options that include overhead lighting, bin rails, and locking drawers.

You can trust these workbenches' quality, as they're backed by TUV and iNarte certifications. Whether you choose flat or perforated tops, you'll get a surface that's both static dissipative and durable.

Major suppliers like Uline and Cir-Q-Tech provide various frame materials, including stainless steel, aluminum, and mild steel, letting you match your specific laboratory requirements.

Industrial Grade Static Control Benches

Industrial-grade static control benches deliver reliable ESD protection through their heavy-duty construction and advanced conductive materials. You'll find these workstations built with fully welded tube steel frames and scratch-resistant ESD powder coatings that guarantee long-term durability in demanding lab environments. These workstations are manufactured in USA to ensure the highest quality standards and strict adherence to industrial specifications.

| Feature | Benefit |

|---|---|

| Conductive Materials | Provides consistent grounding through metal and carbon-infused surfaces |

| Anti-static Laminates | Offers permanent protection with LisStat™ technology |

| Grounding Systems | Enables safe discharge of static through copper wire connections |

| Insulated Floor Glides | Prevents static transfer from floor to work surface |

| Compliance Standards | Meets ANSI/ESD S20.20 and IEC 61340-5-1 requirements |

The benches' construction incorporates fireproof anti-static laminated countertops that resist wear and high temperatures. You'll need to connect your workbench to the lab's electrostatic grounding point using a copper wire to maintain proper static dissipation. The resistance values must stay between 1.0 x 10^6 and 1.0 x 10^9 Ω to meet industry standards. These benches don't just protect your sensitive equipment; they're built to withstand years of heavy use while maintaining consistent ESD protection levels.

Modular Anti-Static Workstations

Countless labs are turning to modular anti-static workstations for their adaptable ESD protection and space-efficient design. These workstations offer quick assembly and height adjustability, making them perfect for various lab tasks and different users. The integrated power outlets facilitate proper cable management and organized workspaces.

The modular components let you customize your setup by adding or removing parts based on your specific needs.

These workstations incorporate thorough ESD protection measures to safeguard your sensitive electronics. You'll need to guarantee proper grounding systems with resistance under 10 ohm, along with conductive worksurfaces that distribute charges evenly. Don't forget to include anti-static floor mats and central grounding points for connecting ESD accessories like wrist straps.

To maintain ANSI/ESD S20.20 compliance, you'll want to implement regular testing of ESD surfaces and grounding systems. Major manufacturers like LabTech Supply Company and IAC Industries offer workstations with built-in ESD control features.

When setting up your workspace, make sure to include ESD chairs and conductive chair mats to prevent charge discharge. You'll also benefit from ESD floor runners for safely moving sensitive components throughout your lab area.

Heavy-Duty Laboratory ESD Surfaces

Building on the modular workstation foundation, heavy-duty laboratory ESD surfaces provide the robust protection your sensitive equipment needs.

You'll find exceptional durability in materials like phenolic resin, which resists harsh chemicals including nitric acid, acetic acid, and hydrofluoric acid. The durable epoxy surfaces won't discolor, blister, or crack under intense laboratory conditions. The inherent antibacterial properties of phenolic resin eliminate the need for additional microbial additives.

For the best static control, you'll want to focus on ESD laminate surfaces featuring a carbon layer that maintains surface resistivity between 10^6 and 10^9 Ω/sq. These surfaces include a 180º roll on the front edge, maintaining continuous conductivity across your work area.

The stainless steel under core prevents water penetration and adds structural integrity to wood core constructions.

You'll need to maintain these surfaces properly to guarantee lasting performance. Clean electrical contact points with denatured alcohol and implement constant monitoring systems to verify ESD control effectiveness.

Don't forget to take into account your work area's relative humidity and ionization levels when selecting surface materials. With proper installation of grounding points at the rear of the workbench and regular maintenance, your heavy-duty ESD surfaces will provide reliable protection against static discharge.

Compact ESD-Safe Technical Benches

Three essential features define compact ESD-safe technical benches: space efficiency, static protection, and modular design. You'll find these workstations equipped with high resistance dissipative surfaces ranging between 1 x 10^5 and 1 x 10^11 ohms/square, guaranteeing ideal static discharge protection for your sensitive electronic components.

The benches integrate seamlessly with your laboratory space through customizable configurations and double workbench options that maximize floor space while reducing costs. These benches are constructed with conductive laminate materials that ensure reliable static discharge control.

When selecting your compact ESD bench, you'll need to think about these critical components that guarantee both safety and functionality:

- Static dissipative materials throughout all surfaces, including shelves and storage units, connected to a common grounding point

- High-pressure laminate or ESD powder-coated steel construction for durability and spill resistance

- Integrated storage solutions with adjustable shelves and ESD-safe containers

- Ergonomic features like height adjustment and proper load capacity ratings

- Compliance with IEC 61340-5-1 standards and EPA requirements

You can further enhance your workstation's functionality with ESD wrist straps, proper lighting fixtures, and power panels with protective contacts. Each bench comes with configuration options to meet your specific laboratory requirements while maintaining essential ESD protection.

Frequently Asked Questions

How Often Should ESD Mats and Grounding Straps Be Tested for Effectiveness?

You should test your ESD mats quarterly for resistance measurements, while your grounding straps need daily testing if used regularly. You can replace daily strap testing with continuous monitoring systems for better reliability.

Can Regular Cleaning Products Be Safely Used on Anti-Static Workbench Surfaces?

No, you shouldn't use regular cleaning products on anti-static surfaces. They'll leave residues that attract static and damage protective properties. Instead, you must use specialized ESD cleaners to maintain surface effectiveness.

What Humidity Levels Are Optimal for Maintaining ESD Workbench Performance?

You'll want to maintain humidity levels between 40-60% RH for ideal ESD workbench performance. Don't let it drop below 30% as this increases static risks, or exceed 70% which can cause corrosion.

Do ESD Workbenches Require Special Lighting to Prevent Static Buildup?

Yes, you'll need specialized ESD-safe lighting with static-dissipative materials and proper grounding. LED lights or luminescent lamps with shadowless reflectors are ideal choices to prevent static buildup at your workbench.

How Long Do Anti-Static Treatments Typically Last Before Requiring Reapplication?

You'll find that anti-static treatments vary widely – internal additives can last years, while external sprays need reapplication every few months. Humidity, usage, and cleaning frequency will impact how long they'll remain effective.

In Summary

You'll find these five anti-static workbench solutions offer reliable protection for your sensitive electronic components and laboratory equipment. Whether you're choosing premium stainless steel, industrial-grade surfaces, or compact technical stations, investing in quality ESD protection is vital. Don't compromise on your workspace safety – select the bench that best fits your lab's specific needs and space requirements.

Leave a Reply