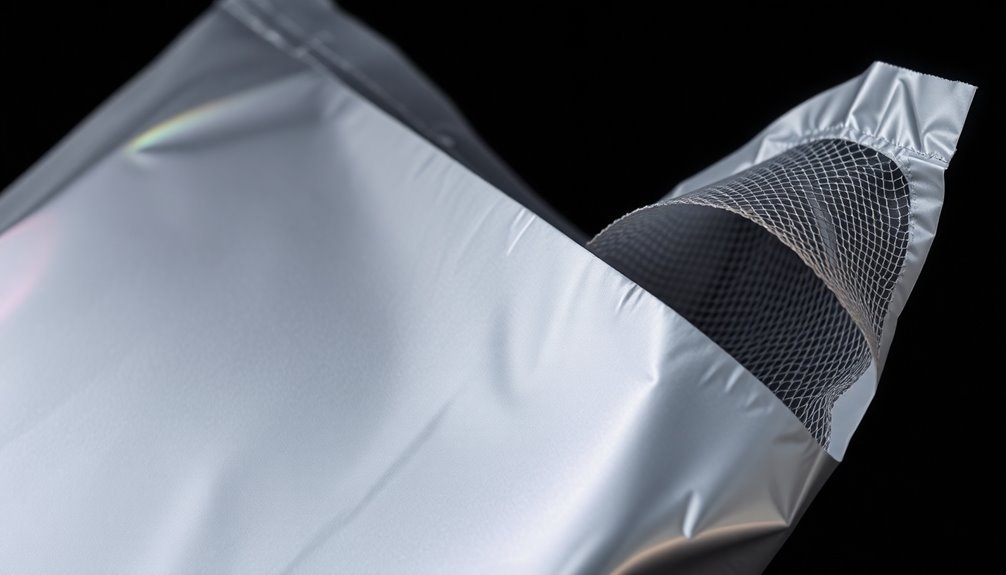

Static shielding bags block electricity through their sophisticated three-layer construction. You'll find an inner layer made of static dissipative polyethylene that prevents charge buildup, a middle metallic layer (usually aluminum or carbon) that creates a Faraday cage effect, and an outer layer of coated polyester that removes external charges. When you seal the zip lock, these layers work together to redistribute electrical charges across the surface instead of letting them reach your sensitive electronics inside. The metallic shield acts like a protective force field, similar to how a coaxial cable blocks interference. Understanding how each layer functions reveals the full scope of their protective capabilities.

The Science Behind Static Bags

The static shielding bags' sophisticated design includes an inner dissipative polyethylene layer, a middle aluminum shielding layer, and an outer polyester layer with static dissipative coating.

This construction effectively distributes and grounds static charges while providing thorough protection against ESD. Dissipative anti-static bags help prevent internal static buildup within the package.

Some bags offer additional safeguards, including moisture vapor barrier, electromagnetic interference, and radio frequency interference shielding.

For maximum protection, you must guarantee the bag is properly sealed without staples or sharp edges that could compromise its shielding properties.

Understanding Faraday Cage Protection

You'll find that static bags incorporate a Faraday cage design where metallic layers distribute electrical charges across their surface, keeping sensitive components safe inside.

The conductive material spreads incoming charges evenly throughout the bag's exterior, preventing harmful electrical currents from reaching the protected electronics. This protective mechanism mirrors how electrical shocks run harmlessly along a Faraday cage's outer surface.

When static or electromagnetic forces contact the bag's surface, the metallic shield redistributes these charges away from your valuable components, maintaining a neutral environment within.

Metallic Shield Distribution Mechanics

Understanding how Faraday cages protect against electromagnetic fields starts with electrostatic induction. When an external electric field approaches the metallic shield of a static bag, free electrons within the conductive material instantly respond.

These electrons redistribute themselves along the surface, with positive charges remaining fixed in place. This creates an opposing electric field that effectively cancels out the incoming field, protecting your sensitive electronics inside. Solid metal sheets provide superior protection compared to mesh materials.

The effectiveness of this shielding depends heavily on the material's properties and construction. You'll find that copper and aluminum work exceptionally well due to their high conductivity.

The thicker the material, the better it shields against electromagnetic interference, though there's always a practical balance between protection and usability.

- You're witnessing quantum-level defense as billions of electrons move in perfect coordination

- Your devices are protected by the same principle that safeguards aircraft from lightning strikes

- You're harnessing one of nature's most elegant protective mechanisms

- Your sensitive electronics remain safe thanks to this invisible electromagnetic barrier

The metallic shield must be continuous and properly sealed to maintain its protective capabilities. Any gaps larger than one-tenth of the incident wave's wavelength can compromise the shielding effectiveness.

Charge Flow Prevention Design

Deep within the design of static-protective bags lies a sophisticated charge flow prevention system based on Faraday cage principles. You'll find that these bags utilize conductive materials, typically aluminum or copper layers, that redistribute electrical charges across their surface while preventing them from reaching the contents inside. Vacuum-deposited metal films on plastic materials are commonly used in the manufacturing process to achieve optimal shielding properties.

| Design Element | Prevention Mechanism |

|---|---|

| Conductive Layer | Redistributes charges across surface |

| Material Thickness | Increases electromagnetic attenuation |

| Continuous Shield | Blocks wavelengths shorter than material depth |

| Seal Design | Prevents charge leakage at closure points |

| Surface Treatment | Enhances conductivity for better protection |

The effectiveness of your static bag's charge prevention system depends on its construction quality. You'll notice that the bags don't have holes or gaps that could compromise their shielding capability, as any opening larger than 3mm could allow high-frequency electromagnetic waves to penetrate. The bags' metallic layers work similarly to a coaxial cable's shielding, creating a protective barrier that stops both incoming and outgoing electromagnetic interference. When you seal the bag properly, you're completing the Faraday cage effect, ensuring your sensitive electronics remain protected from electrostatic discharge and RF interference.

Materials That Block Electricity

Electrical insulators serve as nature's barriers against the flow of electricity. When you examine the materials used in zip lock static bags, you'll find they're designed with specialized insulating properties.

These materials, like polymers and anti-static compounds, prevent electrons from moving freely by keeping them tightly bound to their atomic nuclei. Glass and rubber are other common insulators used in electrical safety applications.

The effectiveness of insulating materials depends on their resistivity and dielectric strength. You'll find both natural and synthetic insulators working together to create a protective shield around sensitive electronics. High-quality static bags combine multiple insulating properties to guarantee maximum protection.

Here's why these insulating materials matter for your electronic components:

- They'll protect your devices from sudden electrical discharges that could fry circuits

- They'll maintain the integrity of sensitive microchips during transport

- They'll prevent static buildup that could silently damage components

- They'll shield against external electromagnetic interference

Understanding these materials helps you appreciate why zip lock static bags aren't just ordinary plastic. They're engineered with specific insulating materials that create a barrier against electrical current flow, making them essential for protecting your valuable electronic components during storage and transportation.

Layer By Layer Breakdown

Protection comes from precision engineering in zip lock static bags, where multiple specialized layers work together to shield your electronic components. Each layer serves a distinct purpose in creating a thorough defense system against electrical damage. The bags contain a microscopic water layer that helps reduce the chances of unwanted discharge.

| Layer | Location | Primary Function |

|---|---|---|

| Static Dissipative Polyethylene | Inner | Prevents static buildup on stored items |

| Carbon/Aluminum Shield | Middle | Creates Faraday cage, grounds charges |

| Coated Polyester | Outer | Blocks external electrical charges |

You'll find the inner layer made of static dissipative polyethylene, which immediately tackles any potential static buildup from your stored components. The middle layer, constructed from either carbon or aluminum, acts as a conductor that collects and grounds any electrical charges that might threaten your electronics. The outer layer features a static dissipative coating on polyester that repels external electrical charges while adding structural strength. When properly sealed, these three layers create a Faraday cage that meets strict industry standards like ANSI/ESD S20.20 and EIA-541. The 3-mil thickness and double-track zipper closure guarantee you're getting reliable protection that's both durable and reusable.

Static Dissipation Process

When you open a zip lock static bag, you'll notice its sophisticated layered protection system working to redirect static charges away from your sensitive electronics.

The outer dissipative layer acts as your first line of defense, channeling static electricity across the surface rather than allowing it to build up in one spot. This layer features a resistance of 10^5-10^11 ohms that enables controlled discharge of static electricity.

Your components remain safe as the bag's conductive layer then redirects any remaining charges through a controlled path to ground, preventing sudden discharges that could damage electronics.

Layered Protection Mechanism

Zip lock static bags employ a sophisticated three-layer system that works together to protect sensitive electronic components from static discharge. Each layer serves a distinct purpose in creating a complete shield against harmful static electricity.

The inner layer, made from static dissipative polyethylene, provides a gentle surface that won't generate static when it contacts your valuable electronics.

In the middle, you'll find a conductive layer of aluminum or carbon that acts as the primary defense, creating a Faraday cage effect that grounds external charges before they can reach your components.

The outer layer features a special static dissipative coating that prevents charge buildup on the bag's surface.

Here's why this layered approach is vital for protecting your electronics:

- Your expensive components stay safe from both internal and external static threats

- You won't risk damaging nearby equipment due to static discharge

- Your sensitive electronics remain protected during shipping and storage

- You can handle the bag without worrying about generating harmful static charges

This multi-layer protection system guarantees that static electricity can't penetrate the bag from any direction, keeping your valuable electronic components safe and functional.

Charge Flow Redirection

Static electricity follows a precise path through the sophisticated dissipation system of static bags. When you place an electronic component inside, the bag's conductive layers immediately begin redirecting any potential charges.

The bag's outer dissipative coating serves as your first line of defense, actively removing external electrical charges before they can cause damage.

The bag's middle layer, made from carbon or aluminum, acts as your Faraday cage. This means it'll collect incoming charges and distribute them evenly across the surface, preventing them from reaching your sensitive components. You're getting protection through a controlled charge flow that moves at a slower, safer rate to ground.

What you're witnessing is a three-part protection system: the prevention of tribocharging, the redistribution of existing charges, and the grounding of potentially harmful static buildup.

Your static shielding bag's surface resistance, typically ranging from 10^3 to 10^5 ohms, guarantees charges flow to ground rather than through your valuable electronics. This redirection process works continuously, whether you're storing components in an ESD-safe environment or transporting them between facilities.

Conductive Shielding Properties

The conductive shielding properties of anti-static bags rely on a sophisticated combination of materials and design features. These bags use conductive materials with surface resistance less than 1.0 × 10^4 ohms, creating a protective Faraday Cage around your sensitive electronics.

Most bags are made from either low density polyethylene or polyethylene terephthalate, with a metalized ESD shielding layer and an anti-static dissipative inner liner.

When you're handling electronic components, you'll want to understand these essential protective features:

- A microscopic layer of water molecules at the film's surface actively fights static electricity build-up, protecting your valuable components.

- The metallic pink or silver coating isn't just for show – it's an important indicator of the bag's protective capabilities.

- The double-track static dissipative zipper closure provides an extra barrier against harmful electrical charges.

- The conductive materials woven throughout the bag create a complete shield, safeguarding your electronics from every angle.

The bag's conductive properties don't just dissipate static charges – they create an extensive blocking mechanism that shields your components from potentially destructive electrostatic discharge, ensuring their safety during storage and transport.

Moisture Protection Features

When protecting sensitive electronic components, moisture barrier protection proves just as essential as static defense. You'll find that moisture barrier bags utilize multiple layers of impermeable materials like polyethylene, nylon, and metallized films to achieve low Moisture Vapor Transmission Rates (MVTR). These bags work alongside desiccants to keep your components dry during manufacture, transportation, and storage.

| Protection Feature | Benefit to You |

|---|---|

| Multi-layer Construction | Guarantees consistent moisture blocking |

| Puncture Resistance | Protects your investment during handling |

| Resealable Closure | Allows repeated access while maintaining protection |

| Humidity Indicators | Lets you monitor moisture exposure |

| Desiccant Compatibility | Provides additional moisture absorption |

You'll notice these bags meet IPC/JEDEC J-STD-033 requirements, making them suitable for long-term storage of electronics that require dry conditions until reflow soldering. The bags' construction features puncture-resistant materials measured in pounds of force, guaranteeing your components remain protected. When you're working in electronics manufacturing, aerospace, or medical device industries, these moisture barriers become vital for maintaining component reliability. For superior results, you can combine these bags with industrial vacuum sealers and humidity indicator cards to monitor internal conditions.

Zip Lock Design Benefits

To split the provided text into separate paragraphs, you can break it up based on the natural flow and logical divisions of the content. Here is the text with the long paragraphs split:

You'll find that zip lock static bags feature a robust sealing mechanism that reliably clicks shut with each use, protecting your sensitive electronic components.

The dual-track design guarantees consistent closure strength even after hundreds of opening and closing cycles, maintaining the bag's protective qualities throughout its service life.

Your electronics remain safe from static discharge and environmental threats thanks to the precision-engineered closure that forms a complete seal every time you press the tracks together.

Reliable Resealing Mechanism

Designed with precision engineering, zip lock static bags feature innovative closure mechanisms that provide consistently reliable resealing capabilities. These bags utilize interlocking structures along the mouth that click together securely when you press opposite sides against each other.

The mechanical function guarantees you'll achieve a consistent seal every time you close the bag, whether you're using traditional press-to-close or slide-lock closures.

The resealing mechanism's effectiveness stems from four key advantages:

- You can trust the catch mechanisms to prevent accidental openings, as they're designed to resist movement in the opposite direction

- You'll maintain the static-free environment inside the bag thanks to the tight seal that blocks both air and moisture

- You're able to repeatedly open and close the bag without compromising its protective qualities

- You can verify the seal's integrity through both tactile and visual confirmation

The combination of cooperating interlocking structures and mechanical sliders guarantees your sensitive components remain protected. Whether you're squeezing incremental portions of the mouth or using the slider mechanism, you'll achieve a dependable seal that maintains the bag's static shielding properties.

Protection During Multiple Uses

Building upon the reliable sealing mechanism, zip lock static bags offer significant advantages for multiple uses over time. You'll find that these bags maintain their protective qualities through repeated openings and closings, thanks to their multilayered construction featuring conductive and static dissipative materials.

The reusable nature of these bags directly supports sustainability efforts while ensuring consistent protection for your sensitive components.

When you're working with electronic parts regularly, you'll appreciate how the bags' static shielding properties remain effective through multiple access cycles. The Faraday cage design, created by the conductive middle layer typically made from carbon or aluminum, continues to dissipate static charges effectively even with frequent use.

You're also getting ongoing protection against moisture and oxidation, which is essential for maintaining component integrity over extended periods.

You can optimize your storage space by reusing these bags for different components as needed. Their zip lock mechanism allows you to quickly access and reseal the contents while maintaining the static-safe environment.

This means you're not only protecting your components but also reducing waste and operating costs through repeated use of the same protective packaging.

Military Grade Standards

Meeting rigorous military specifications, static shielding bags used in military applications must comply with strict standards like MIL-PRF-81075 and MIL-B-81705.

These bags are constructed with three essential layers: an inner static dissipative layer, a middle aluminum shielding layer, and an outer polyester layer, typically measuring 3 mil in thickness. They're designed to work as Faraday cages, effectively dissipating and blocking static electricity while protecting sensitive electronics.

When you're dealing with military-grade static shielding bags, you can trust their effectiveness because they must meet these critical requirements:

- Complete ESD/EMI barrier protection, ensuring your sensitive electronics stay safe from both static discharge and electromagnetic interference

- Superior moisture resistance with low MVTR ratings, protecting your components in high-humidity environments

- Enhanced puncture and tear resistance, giving you confidence during handling and transportation

- RoHS and IEC 62321 compliance, meeting international environmental standards

These bags must also satisfy specific Type and Class requirements, such as MIL-DTL-117H Type I Class F Style I. With their multi-layer construction and certified performance standards, you're getting maximum protection for your military electronics.

Common Storage Applications

Protecting sensitive items effectively requires understanding the diverse applications of zip lock static bags. These versatile storage solutions serve critical functions across multiple industries and personal uses.

In the electronics sector, you'll find these bags safeguarding components like microprocessors, semiconductors, and circuit boards from electrostatic discharge and moisture damage. The bags provide essential protection for sensitive electronic parts that could be compromised by static buildup or environmental factors.

For medical applications, you can use these bags to store and transport pharmaceuticals, medical samples, and sensitive equipment. They're designed with airtight seals that prevent contamination while maintaining clear visibility for quick identification and compliance with medical standards.

When it comes to important documents, you'll benefit from these bags' ability to protect passports, certificates, and archived records from moisture and dust while ensuring easy access.

For travel purposes, you can rely on them to organize toiletries, protect electronics, and comply with TSA regulations thanks to their leak-proof design and transparent construction.

In each application, these bags combine protection against static electricity with specific features tailored to your storage needs.

Testing And Certification Requirements

Numerous testing and certification requirements govern the manufacturing and use of zip lock static bags, guaranteeing they provide reliable protection for sensitive components.

You'll need to verify that your bags meet IEC regulations, MIL-PRF-81705 specifications, and EIA-541 standards for static shielding. These requirements include testing for Faraday cage effectiveness, static dissipation rates, and material resistance under various humidity conditions.

When selecting zip lock static bags, you must understand the distinction between static shielding and anti-static materials. Type C bags require grounding, while Type D bags don't. You'll also need to guarantee RoHS compliance and proper material specifications for thickness and composition.

Your components' safety depends on rigorous Faraday cage testing that confirms the bag's ability to block harmful electric charges.

Your peace of mind comes from seal integrity testing that guarantees complete protection.

Your investment is protected through thorough static dissipation testing.

Your compliance is assured through proper documentation and certification marks.

Always check the government-maintained Qualified Product List and product documentation to verify MIL-PRF-81705 certification. Remember to look for proper certification marks that indicate compliance with relevant standards.

Best Handling Practices

Safe handling protocols form the backbone of effective static protection. You'll need to maintain a clean workspace and guarantee proper grounding of both personnel and equipment before handling any static-sensitive components.

It's crucial to wear static protective clothing and use static-safe tools during all handling procedures.

When you're working with zip lock static bags, handle them gently and minimize unnecessary movement of the components inside. You'll want to avoid direct contact between sensitive items and external objects, always using the bags as intended.

Make sure you're sealing the bags properly to maintain their protective properties.

Store your bagged components in a dry environment, away from heat sources, using properly labeled static-safe containers. You shouldn't expose the components to external environments more than necessary, as this can lead to static buildup.

For shipping, you'll need to use appropriate static shielding materials and guarantee the bags are completely sealed. Secure the components to prevent movement during transport, and always include clear static warning labels on the packaging.

Maintain proper documentation to track how the components are handled throughout their journey.

Frequently Asked Questions

Can Static Bags Be Reused, and How Many Times Before Losing Effectiveness?

You can reuse static bags if they're undamaged and properly sealed. While there's no fixed limit, you'll need to inspect them before each use to verify they maintain their protective integrity and shielding capabilities.

What Temperature Ranges Can Zip Lock Static Bags Safely Withstand?

You can safely store your zip lock static bags between 21°C to 23°C, though they're capable of withstanding much higher temperatures up to 211°C. They also show good resistance to cold temperatures.

Do Zip Lock Static Bags Expire or Have a Recommended Shelf Life?

While zip lock static bags don't have a set expiration date, you'll want to inspect them regularly. They'll stay effective if you store them at 68°F in a dry place away from sunlight and moisture.

Can These Bags Protect Against Electromagnetic Radiation From Nearby Electronics?

Yes, your static shielding bags can protect against electromagnetic radiation from nearby electronics. Their aluminum layer and Faraday cage design provide EMI attenuation exceeding 50 dB, effectively blocking electromagnetic interference from surrounding devices.

Are Zip Lock Static Bags Recyclable or Environmentally Friendly?

Yes, you can recycle zip lock static bags if they're clean and properly sorted. They must be taken to specific recycling locations. While recyclable, biodegradable alternatives and reusable options are more environmentally friendly choices.

In Summary

You've learned that zip lock static bags rely on multiple conductive layers forming a Faraday cage effect to block electrical charges. They'll protect your sensitive electronics through static dissipation and electromagnetic shielding. When you're handling components, remember that certified static bags meet strict military and industry standards. Store your devices properly, and they'll stay safe from damaging electrical charges and interference.

Leave a Reply