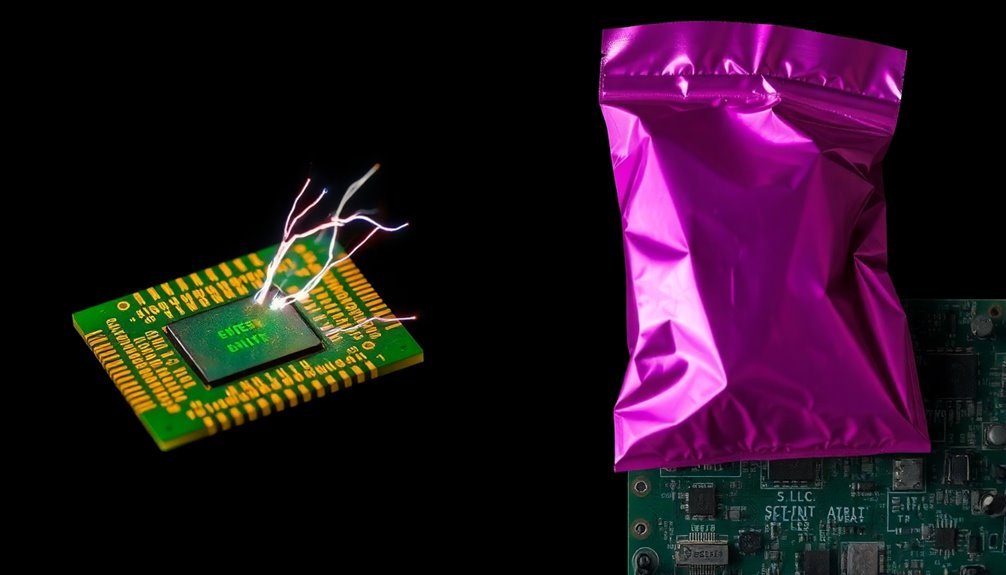

Your unprotected electronics face constant danger from static electricity that builds up during everyday activities like walking across carpet or handling synthetic materials. While your body can generate up to 25,000 volts through normal movement, it only takes 4,000 volts to damage sensitive electronic components. This invisible threat can cause immediate failure, latent defects, or complete destruction of circuit boards and semiconductors. That's why you'll need proper static-safe storage solutions like ESD bins and shielding bags to protect your valuable devices. Understanding the full scope of static protection can save you from costly repairs and replacements.

Understanding Static Electricity Risks

While many people are familiar with the shock of static electricity when touching a doorknob, its impact on electronics can be far more severe.

Static electricity builds up easily in everyday situations, particularly when you're walking across carpets or handling synthetic materials in office environments. What's more concerning is that climate-controlled spaces with dry air substantially increase the risk of static build-up. The aerospace and healthcare industries are especially vulnerable to these risks.

You'll find that static electricity poses serious threats to electronic devices. When electrostatic discharge (ESD) occurs, it can instantly damage sensitive components, create hidden defects that emerge later, or completely destroy your electronics.

The damage isn't limited to electronic components – mechanical parts like bearings can also suffer. In worst-case scenarios, static electricity can even trigger fires or explosions when flammable materials are present.

What makes static electricity particularly dangerous is that it thrives in common workplace conditions. Low humidity levels, abundant synthetic materials, and constant human movement create perfect conditions for static build-up.

When you're dealing with valuable electronic equipment, these seemingly harmless environmental factors can lead to substantial financial losses through repairs, replacements, and operational downtime.

The Human Body Voltage Factor

In everyday situations, your body acts as a substantial conductor of electrical charges, capable of storing and transferring static electricity that can damage sensitive electronics.

Your body's electrical resistance typically ranges from 500 to 3,000 ohms, with internal resistance around 300 ohms, making you an efficient carrier of potentially harmful static charges. The presence of bone and fat tissue offers higher resistance compared to muscles and nerves.

You'll generate varying levels of static electricity during routine activities, and your body's conductivity changes based on several factors. When you're sweating or have moist skin, your resistance decreases markedly, making you more conductive. Similarly, if you have cuts or breaks in your skin, you'll have lower resistance and increased conductivity.

Understanding your body's role in static electricity transfer is vital for protecting sensitive electronics. You're constantly exposed to AC electric fields from various sources, and your body voltage can fluctuate considerably.

To prevent damage to electronic components, you'll need to account for these factors when handling devices. That's why proper static-safe storage solutions are essential – they help protect against the unpredictable nature of human body voltage and its potential to cause ESD events that can melt or damage electronic parts.

Protecting Sensitive Electronic Components

Most electronic components require robust protection against static electricity due to their inherent vulnerability to electrostatic discharge (ESD). You'll find that static damage can manifest in three primary ways: catastrophic failures that immediately destroy components, upset failures causing temporary malfunctions, and latent failures that emerge over time.

To protect your sensitive electronics, you'll need to implement thorough static control measures, especially when handling integrated circuits and semiconductors. ESD storage bins play a vital role in maintaining component integrity during storage and transport. Since sensitive components can be damaged at operating pressures of just 5 to 8 bar, extreme care must be taken during all handling procedures.

| Protection Level | Component Type | Recommended Storage |

|---|---|---|

| High | Integrated Circuits | ESD-Safe Bins with Foam |

| High | PCB Assemblies | Static-Shielding Bags |

| Medium | Cable Assemblies | Conductive Containers |

| Medium | Power Supplies | ESD-Safe Shelving |

| Low | Metal Components | Standard Bins |

You'll also want to incorporate additional protective measures like surge protectors and proper grounding systems. When you're setting up your storage area, make certain it's equipped with static-dissipative flooring and maintain appropriate humidity levels. Remember that preventing static damage isn't just about protecting components—it's about preserving your investment and maintaining product reliability.

ESD Storage Bin Features

Your choice of ESD storage bin material directly impacts its static-protection capabilities, with anti-static HDPE and carbon-infused conductive options giving you different levels of charge dissipation.

You'll find anti-static bins in blue and conductive bins in black, making it easy to identify the right container for your specific electronic components. These bins are resistant to chemicals and can withstand exposure to most oils, acids, and alkalis.

The stackable design of these bins lets you maximize your storage space while maintaining proper ESD protection throughout your facility.

Material Composition Matters

Through careful material selection, ESD storage bins deliver exceptional protection for sensitive electronics. You'll find these bins are primarily constructed from polypropylene, a material that's remarkably resistant to oils, acids, and alkalis.

The conductive materials integrated into their design guarantee rapid dissipation of static electricity, meeting strict IEC 61340 standards. These containers come in various designs including skeleton and folding options for different storage needs.

What makes these bins particularly valuable is their impressive thermal stability, allowing them to function effectively in temperatures ranging from -20° to +100° Celsius. Their surface resistance, measured between 10^3 to 10^9 ohms, provides ideal static dissipation to protect your sensitive components.

When you're handling electronic components, you'll appreciate that these bins aren't just protective – they're also practical. The injection molding process creates robust containers with smooth interiors that prevent component damage and make cleaning effortless.

You can customize them with dividers, inserts, and partitions to meet your specific storage needs. Plus, they're made from recyclable materials, supporting sustainable manufacturing practices while maintaining their primary function of protecting electronics from static damage.

The non-toxic composition guarantees they're safe to use in any manufacturing environment.

Stackable Design Benefits

Inside modern manufacturing facilities, stackable ESD storage bins revolutionize component organization while maintaining critical static protection. You'll find these versatile containers designed with wide ledges and hanging lips that enable both vertical stacking and rail mounting options. With a load capacity of 5kg, these bins provide robust storage for a variety of electronic components.

This adaptable design maximizes your available space while ensuring easy access to stored components.

When you're managing electronic components, you'll appreciate these key advantages of stackable ESD storage:

- Space optimization – You can stack bins vertically to reduce floor space requirements and create denser storage configurations that keep your workspace organized.

- Component protection – The secure stacking system prevents bins from toppling, while the ESD-safe materials shield your sensitive electronics from static damage.

- Operational efficiency – You'll experience streamlined logistics and reduced handling costs through improved organization and decreased component failure rates.

The flexibility of stackable ESD storage extends beyond basic organization. You can customize your storage solution with optional dividers and covers to meet specific component needs.

Whether you're working in manufacturing, packaging, or long-term storage, these bins adapt to your changing requirements while maintaining consistent static protection throughout your operation.

Cost Benefits of ESD Protection

The financial wisdom of investing in ESD protection becomes crystal clear when examining industry data. With ESD damage costing the electronics industry approximately $5 billion annually, you'll find that implementing protective measures is substantially more cost-effective than dealing with the consequences of static damage.

| Cost Impact Area | Savings Potential |

|---|---|

| Production Waste | Reduced scrap and rework costs |

| Customer Relations | Avoided warranty claims and recalls |

| Manufacturing Time | Decreased production delays and repairs |

You'll see immediate benefits in your production processes when you implement proper ESD storage solutions. These protective measures help you avoid costly repairs, minimize material waste, and maintain efficient production flows. More importantly, you're protecting your company's reputation by preventing product failures that could lead to loss of customer confidence. The proper use of antistatic materials and packaging during storage and handling ensures maximum protection of sensitive electronic components.

The investment in ESD protection pays for itself through multiple channels. You'll save on materials by reducing component damage, cut labor costs by avoiding rework, and prevent expensive product recalls. When you consider that the implementation costs are relatively low compared to the potential financial impact of ESD events, it's clear that ESD protection isn't just a safety measure—it's a smart business decision.

Manufacturing Process Safety Standards

Building on the financial benefits of ESD protection, implementing thorough safety standards across manufacturing processes safeguards both workers and sensitive electronic components. You'll need to focus on extensive safety measures that address electrical hazards, chemical handling, and static control throughout your manufacturing environment. Static discharge control is especially critical as improper battery handling can lead to dangerous fires or explosions in manufacturing facilities.

To maintain effective safety standards in electronics manufacturing, you must:

- Establish rigorous cleanroom protocols with proper environmental controls, regular equipment inspections, and maintenance schedules to prevent contamination and guarantee worker safety.

- Implement proper storage solutions using ESD-safe materials that comply with EN 61340-5-1 standards, including specialized cabinets, bins, and racks designed for static-sensitive components.

- Provide thorough worker training on safety procedures, hazard identification, and proper use of personal protective equipment.

You'll want to regularly conduct safety audits and maintain emergency response plans for potential hazards like fires, explosions, or chemical releases. When handling hazardous materials, guarantee you're following regulatory guidelines and using appropriate static-safe storage solutions.

Don't overlook the importance of proper tool safety and electrical precautions, as these are vital aspects of maintaining a secure manufacturing environment.

Long Term Storage Considerations

Successful long-term storage of electronic components demands meticulous attention to environmental controls and protective measures. You'll need to start by consulting the manufacturer's guidelines for specific storage requirements and ensuring your facility meets these standards.

When storing electronics long-term, you must maintain strict control over temperature and humidity levels to prevent moisture damage. Don't store batteries with electronic components, as they can leak and cause corrosion.

Instead, focus on using appropriate anti-static packaging materials like HDPE or containers with carbon black for conductivity and grounding.

You'll want to implement packaging that meets ESD protection standards like MIL-B-81705-B and follows DIN EN IEC 62435 guidelines for long-term storage. Make sure you're using materials with high-impact strength that can withstand warehouse conditions.

Keep your storage area clean, dust-free, and away from direct sunlight.

Regular inspection and analysis are vital parts of your storage protocol. You should test surface resistance periodically to confirm anti-static requirements are being met.

Remember to take into account any industry-specific requirements that might apply to your components, particularly in sectors like automotive manufacturing.

Environmental Control Methods

You'll need to focus on humidity control first, as maintaining levels between 40% to 60% relative humidity is essential for preventing both moisture damage and static electricity buildup in your stored electronics.

Your storage area's temperature should stay between 20 to 25 degrees Celsius to protect components from thermal stress and unwanted chemical reactions.

These two environmental factors work together to create a stable storage environment, with proper humidity being especially critical for static prevention.

Humidity Levels Matter Most

Maintaining proper humidity levels consistently ranks among the most critical factors in protecting electronic components during storage and manufacturing. You'll need to keep humidity between 30% and 50% RH for storage, while manufacturing environments can tolerate up to 70% RH.

When humidity strays outside these ranges, you're risking serious damage to your electronic components.

High humidity poses significant threats to your electronics through:

- Condensation inside enclosures, leading to short circuits

- Degradation of insulating materials, creating unwanted electrical paths

- Corrosion of metal components, compromising circuit integrity

You'll face equally challenging issues with low humidity, as it increases the risk of electrostatic discharge (ESD). Without adequate moisture in the air, static electricity builds up more easily and can discharge unexpectedly, damaging sensitive components.

That's why you'll need proper humidity control measures, such as adiabatic air humidifying systems and air filtration equipment. These systems help maintain ideal conditions and protect your electronics from both moisture-related damage and ESD events.

Don't forget to conduct regular site assessments to verify your humidity control strategy remains effective for your specific manufacturing or storage environment.

Temperature Range Requirements

While proper humidity control protects against moisture damage and ESD, temperature management plays an equally vital role in electronic component storage. You'll need to maintain specific temperature ranges to prevent thermal stress and chemical reactions that can degrade your components over time.

| Temperature Range | Component Type/Purpose |

|---|---|

| 20-25°C (68-77°F) | Typical Storage Range |

| -40°C to 125°C | Integrated Circuits |

| -55°C to 125°C | Passive Components |

| 55-70°F (13-21°C) | Self-Storage Units |

To protect your electronic components, you'll want to implement climate-controlled storage solutions that maintain temperatures between 20-25°C (68-77°F). This range minimizes thermal stress while preventing material degradation. When temperatures exceed 30°C, especially with high humidity, you're risking moisture uptake and accelerated chemical breakdown of components.

You can monitor and maintain proper temperature ranges by installing temperature sensors in your storage area. If you're using a self-storage facility, make sure it's climate-controlled and maintains temperatures between 55-70°F. For sensitive components like integrated circuits, you'll need to pay special attention to manufacturer-specific storage requirements, as these can vary based on the component type and intended application.

Moisture and Static Prevention

Protection against moisture and static electricity forms the cornerstone of proper electronics storage. You'll need to address both threats simultaneously to guarantee your devices remain safe and functional.

Moisture can lead to condensation and short circuits, while static electricity poses a serious risk of internal component damage.

To effectively protect your electronics, implement these essential measures:

- Store your devices in cool, dry areas using airtight containers, and avoid humid spaces like bathrooms or kitchens. Add desiccant packets, such as silica gel, which can absorb up to 40% of their weight in water.

- Use ESD-safe containers and work surfaces, and don't forget to employ anti-static wrist straps when handling sensitive components. These tools help dissipate static charges that could otherwise damage your electronics.

- Control the environment's humidity levels using dehumidifiers or air conditioners, as high humidity increases ESD risks. Regular maintenance and cleaning will also prevent dust accumulation that can trap moisture.

Assembly Line ESD Solutions

You'll need to implement three critical ESD safeguards on your assembly line to protect sensitive electronics during production.

To prevent line worker discharge, equip your staff with grounded wrist straps and conductive footwear while installing antistatic mats at workstations.

For conveyor systems and component transfers, you should use properly grounded conductive belting materials and ESD-safe containers that maintain static protection throughout the entire assembly process.

Preventing Line Worker Discharge

An effective assembly line ESD solution starts with extensive protection for line workers who handle sensitive electronic components. You'll need to implement thorough safety measures to prevent static discharge from workers' bodies and clothing that could damage delicate electronics during assembly.

- You must equip your workers with proper ESD protection, including wrist straps connected to ground points and anti-static heel straps that prevent charge buildup while walking. These items need regular testing to verify they're functioning correctly.

- Your workspace requires static dissipative surfaces and anti-static floor mats that create a safe path for electrical charges to discharge harmlessly. Keep humidity levels controlled and remove any materials that could generate static electricity.

- You'll need to establish ongoing training programs that teach proper handling techniques and equipment usage. Regular recertification verifies workers maintain their knowledge and adapt to new safety protocols.

Make sure your workers understand the importance of wearing ESD-safe garments and consistently using their protective equipment.

Conveyor Belt Static Protection

Implementing proper conveyor belt protection stands as a vital component of your assembly line ESD strategy. You'll need to focus on specialized anti-static belts that contain conductive strength layers and maintain a surface resistivity of at least 10^8 to prevent static discharge disruptions.

| Belt Type | Application | Protection Level |

|---|---|---|

| PVC/PU | General Industrial | 10^6 – 10^8 |

| ESD Specific | Electronics Assembly | 10^8 – 10^9 |

| Conductive Grid | High-Risk Areas | 10^6 – 10^7 |

To maintain your conveyor belt's anti-static properties, you'll need regular cleaning and maintenance procedures. When damage occurs, you've got options: hot vulcanization for minor repairs, cold vulcanization for longitudinal wear, and cold bonding for other types of damage. Don't skip maintenance, as it's essential for maintaining ideal ESD protection levels.

Your investment in proper ESD-compliant conveyor systems will pay off through reduced product damage, improved production times, and decreased rework costs. Remember that conveyor belts are just one part of your complete ESD protection strategy – they need to work in conjunction with other ESD control measures like proper grounding and ESD-compliant storage solutions to create a thorough static-safe environment.

Component Transfer Safety Measures

During component transfer operations, maintaining strict ESD safety protocols protects sensitive electronic parts from invisible yet devastating static damage. You'll need to implement proper handling techniques and use specialized equipment to safeguard your components throughout the transfer process.

Before you begin handling components, make sure you've established an ESD-protected area with controlled humidity and temperature.

You'll want to wear anti-static gloves and use a properly connected wrist strap to maintain constant grounding. Remember to handle components only by their edges, avoiding direct contact with pins and leads.

Here are three critical steps you must follow during component transfer:

- Keep components in their static-protective packaging until you're ready to use them, and immediately place unused parts back into ESD-safe containers.

- Use only ESD-safe tools and equipment, including specialized bins and trays for moving components between workstations.

- Maintain strict organization with color-coded storage systems to separate lead-free and tin/lead-based components while safeguarding all storage containers are properly labeled.

Monitor your static levels regularly and inspect your ESD control equipment to maintain consistent protection throughout the transfer process.

Frequently Asked Questions

Can Static-Safe Storage Containers Be Reused After Cleaning?

Yes, you can reuse static-safe storage containers after proper cleaning. Just make certain you're using appropriate cleaners, avoiding harsh chemicals, and following ESD guidelines to maintain the container's static-protective properties between uses.

How Often Should ESD Protection Equipment Be Tested for Effectiveness?

You'll need to test your wrist straps daily, check worksurfaces quarterly, and verify continuous monitors semi-annually. Adjust these frequencies based on your equipment's usage, risk level, and manufacturer's specific guidelines.

Do LED Components Require the Same Level of Static Protection?

Yes, you'll need stringent static protection for LEDs as they're highly sensitive. They can be damaged by just 400-500V of static electricity, requiring proper ESD storage containers and handling procedures to prevent malfunction.

What Temperature Ranges Are Safe for ESD Storage Solutions?

You'll want to keep your ESD storage between 21°C to 23°C (70°F to 74°F) for maximum protection. While electronics can handle 0°C to 70°C (32°F to 158°F), staying near room temperature guarantees best reliability.

Can Regular Plastic Containers Be Converted Into Static-Safe Storage?

You can't effectively convert regular plastic containers into static-safe storage. They lack the necessary conductive properties, and without proper integration of materials like carbon black, they won't meet required ESD protection standards.

In Summary

You'll find that proper static-safe storage isn't just an optional precaution – it's essential for protecting your valuable electronic components. By implementing ESD storage solutions and maintaining environmental controls, you're safeguarding against costly damage and extending the life of your electronics. Don't underestimate the impact of static electricity; even a small discharge can destroy sensitive components. Make the investment in proper storage today.

Leave a Reply