Control moisture in your ESD bins through these seven proven methods: Use vacuum-sealed moisture barrier bags that meet ANSI/ESD S541 standards, implement humidity monitoring systems with real-time alerts, place the correct amount of desiccant packets using DIN 55473 calculations, maintain relative humidity between 40-60% in storage areas, select proper ESD-safe containers made from High Density Polyethylene, guarantee adequate air circulation within bins, and regularly inspect seals and packaging for wear. Understanding these fundamental moisture control techniques will reveal even more ways to protect your sensitive electronic components.

Understanding Moisture Control Fundamentals

To effectively control moisture in your ESD bins, you'll want to use appropriate ESD-safe materials and packaging. These include moisture barrier bags with vacuum or heat sealing capabilities that provide both moisture and static protection.

Maintaining proper temperature and humidity in your controlled environment is essential for preventing moisture-related issues in ESD storage.

Remember to keep your storage areas clean by removing dust and debris regularly, as these can affect moisture control effectiveness.

You should conduct regular checks of your ESD areas to verify that your moisture control measures are working as intended and maintain proper documentation of these inspections.

Vacuum Sealing Best Practices

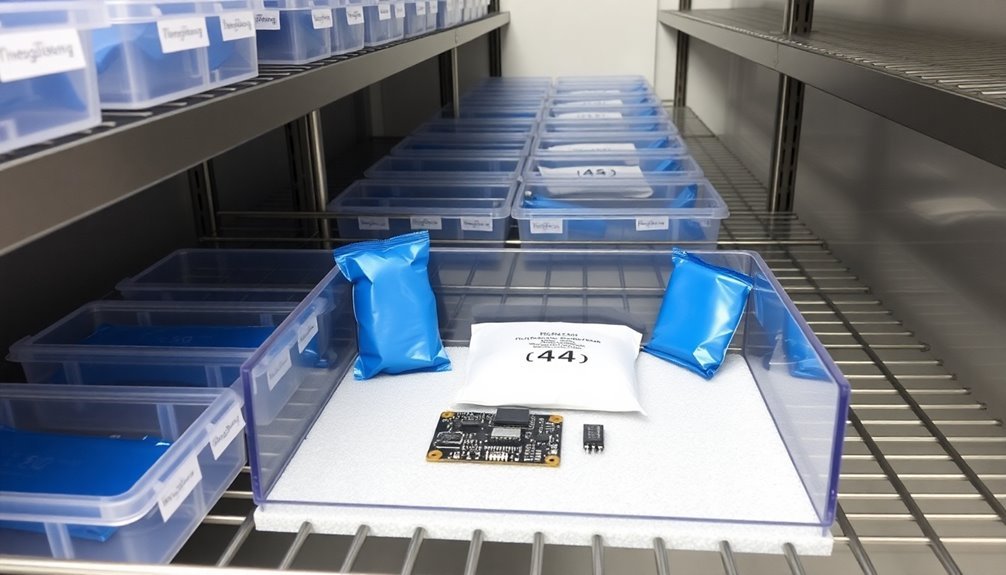

Proper vacuum sealing techniques form the backbone of effective moisture control in ESD-safe environments. To achieve the best results, you'll need to select the right equipment for your specific needs, whether it's a self-contained vacuum sealer or a nozzle-type system for specialized applications like semiconductor processing.

Before sealing, verify that your components are clean, dry, and properly positioned in ESD-compliant bags that meet ANSI/ESD S541 standards. When handling the bags, avoid touching conductive areas and minimize friction to prevent static discharge. After air extraction, heating elements activate to create a reliable seal.

You'll want to place the bag's edge carefully on the seal bar and insert the nozzle for air extraction.

For the most reliable seals, use equipment with triple welding capabilities and advanced controls like PLC systems and vacuum sensors. If you're dealing with liquids or powders, don't forget to use vacuum filters to prevent contamination.

When sealing larger bags, consider dual nozzle systems to increase efficiency and maintain consistent results.

Remember to regularly inspect your equipment and bags for wear or damage, and maintain proper documentation of usage and inspection dates. Store sealed bags in ESD-safe containers with appropriate humidity control to preserve their protective properties.

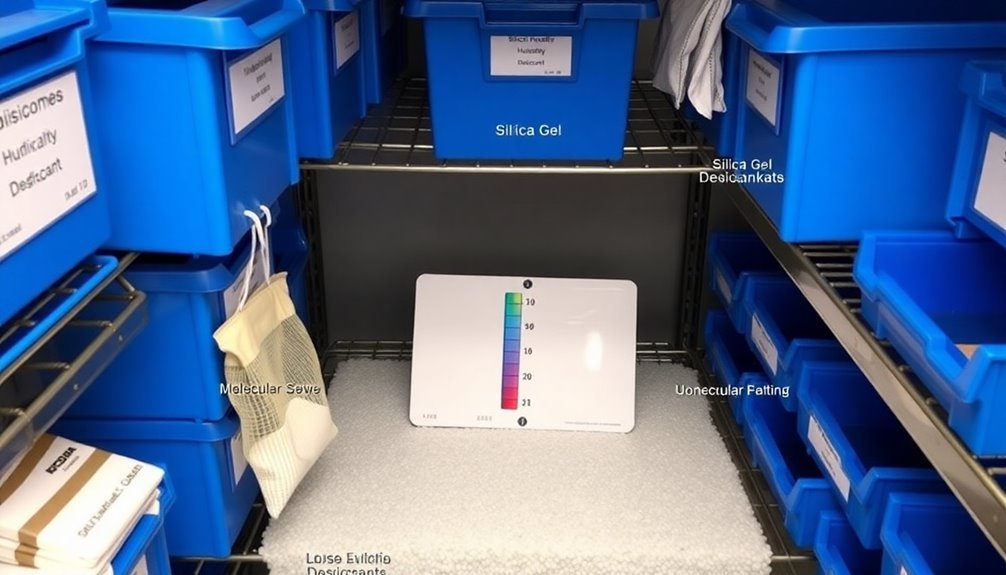

Desiccant Placement and Usage

You'll need to calculate the exact quantity of desiccant packets using DIN 55473 standards based on your ESD bin's interior surface area to guarantee maximum moisture control.

Place your desiccant packets strategically in corners and along walls where moisture tends to accumulate, confirming even distribution throughout the bin. Store unused packets in an airtight container until needed to maintain their effectiveness.

Monitor the desiccant packets' color indicators regularly, as they'll change from blue to pink when they've absorbed their maximum moisture capacity and require replacement.

Optimal Desiccant Packet Quantity

Determining the right amount of desiccant packets for ESD bins requires careful calculation using one of two proven methods. You can use the straightforward MIL-P-116 formula, which multiplies the bag area in square inches by 0.011, or opt for the more detailed EIA 583 formula that factors in additional variables like MVTR and storage duration.

For the MIL-P-116 method, you'll need to measure your bag's surface area and multiply it by 0.011. For example, if you've got a 10" x 20" bag with 2" sides (400 square inches), you'll need 4.4 units of desiccant, rounded up to the nearest half unit. Each pack sized at 1.5" x 3" represents a half unit of desiccant capacity.

The EIA 583 method provides more precision by incorporating moisture vapor transmission rate, storage time, and maximum interior humidity into the calculation.

You'll want to take into account your container's volume and packaging material when selecting desiccant types and quantities. It's crucial to use these packets in sealed moisture barrier bags or containers for maximum effectiveness.

You can pair them with humidity indicator cards to monitor moisture levels and know when to replace or reactivate the desiccants through oven drying.

Strategic Placement Guidelines

Now that you've calculated the right quantity of desiccants, their strategic placement will maximize their effectiveness in your ESD bins. Start by ensuring your bin is clean, dry, and free from any moisture sources or leaks.

You'll need to distribute the desiccant bags evenly throughout the container, paying special attention to corners and areas where moisture tends to accumulate. Consider using horizontal placement patterns to maximize the surface area exposure and absorption capabilities.

When placing desiccants, secure them with adhesive strips or brackets to prevent shifting during transport. Don't block any airflow or ventilation ducts, as proper air circulation is essential for ideal moisture absorption.

Before using your desiccants, keep them in airtight containers to maintain their effectiveness.

For moisture barrier bags (MBBs), you'll want to use a vacuum sealer to remove excess air before heat-sealing. Place your tray stack with desiccants and Humidity Indicator Card (HIC) inside the MBB before sealing.

Remember that desiccants work best in closed moisture barrier packages or rigid, sealed containers. You'll get the best results by combining desiccants with Humidity Control Cards and choosing materials based on your specific absorption rate needs and environmental conditions.

Monitoring Desiccant Color Changes

A desiccant's color-changing properties serve as essential indicators of its moisture absorption status. You'll notice blue indicating silica gel turns pink when saturated, while orange varieties transform to green. These visual cues help you monitor moisture levels in your ESD bins without opening them. For industrial applications, nickel-plated steel indicators provide reliable moisture monitoring at pressures up to 1750 PSIG.

| Desiccant Type | Original Color | Saturated Color |

|---|---|---|

| Blue Silica Gel | Deep Blue | Pink/Purple |

| Orange Silica Gel | Orange/Yellow | Dark Green |

| Desi View | Blue/Orange Mix | Pink/Green Mix |

| Cobalt Chloride | Blue | Pink |

| Methyl Violet | Purple | Pink |

To maximize your desiccant's effectiveness, place packets in corners and crevices where moisture tends to accumulate. You'll need to inspect them regularly and replace or regenerate them when their colors indicate saturation. Consider using humidity indicator cards alongside your desiccants to provide additional moisture monitoring.

You can enhance your moisture control by ensuring your desiccants are properly sealed within moisture barrier bags or containers. If you're managing sensitive electronics or components, don't wait for complete color change – replace desiccants when they're about 75% saturated to maintain ideal protection.

Humidity Monitoring Systems

Your humidity monitoring system should include automated data logging capabilities to track moisture levels continuously within ESD bins.

You'll benefit from real-time alerts that notify you when humidity levels fall outside the critical 40-60% range, allowing for immediate corrective action.

These automated features can integrate with your facility's Wi-Fi network to store historical data in the cloud, making it easier to analyze long-term humidity trends and maintain compliance with ESD standards.

A minimum relative humidity of 15% must be maintained in your storage environment to help minimize static electricity buildup and protect sensitive components.

Automated Data Logging Solutions

In accordance with modern ESD control practices, automated data logging solutions provide thorough humidity monitoring through continuous measurement and documentation.

You'll find these systems actively track and record humidity levels while automatically adjusting gas flow to maintain your specified set points, ensuring ideal moisture control in your ESD bins. The control valve activates whenever humidity rises just 1% above the designated set point.

When humidity levels deviate from predetermined ranges, the system's alarm feature will alert you immediately. This real-time monitoring helps you prevent moisture-related damage to sensitive electronic components.

You can rely on the system's ±2% accuracy between 3-80% RH, giving you precise control over your storage environment.

Your data logging system will generate detailed reports that you can use to analyze humidity trends over time. These insights help you identify patterns and potential issues before they become problems.

You'll also benefit from ESD-safe humidity indicator cards that provide quick visual verification of relative humidity levels inside sealed packages.

When you integrate these automated solutions with your existing desiccator cabinets or glove boxes, you'll maintain compliance with industry standards like MIL-STD-1695, which requires humidity levels between 30-70% RH in areas handling electronic parts.

Real-Time Alert Systems

Real-time alert systems serve as vigilant guardians for your ESD bins by continuously monitoring humidity levels and triggering immediate notifications when conditions fall outside acceptable ranges.

These systems integrate advanced sensors that track both humidity and temperature, ensuring your sensitive electronic components remain protected from ESD risks.

You'll find these systems particularly valuable because they're equipped with customizable threshold settings. When humidity levels drift beyond your specified parameters, you'll receive instant visual and auditory alerts, allowing you to take corrective action before damage occurs.

The systems' data logging capabilities let you analyze historical trends and make informed decisions about your humidity control strategies.

Proper Sealing Materials Selection

Selecting the right sealing materials for ESD bins requires careful consideration of multiple protective properties. You'll need to evaluate materials based on their moisture vapor transmission rate (MVTR), puncture resistance, and compliance with industry standards like MIL-PRF-81705D Type I Class I.

For superior moisture control, you should consider ESD moisture barrier bags with aluminized polyester layers, which provide excellent protection against both moisture and electrostatic discharge. When you're dealing with sensitive components, opt for Dri-Shield bags that offer enhanced puncture resistance and low MVTR values.

If you need reusable options, conductive carbon-loaded polyethylene bags are your best choice, as they won't deteriorate with age or humidity.

You'll want to implement proper sealing practices by using vacuum sealing techniques when possible. Don't forget to include desiccant packs and humidity indicator cards in your packaging system to monitor and maintain appropriate moisture levels.

For clean room applications, you must guarantee your selected materials meet specific environmental requirements. Remember to verify that your chosen materials comply with relevant standards like JEDEC J-STD-033 and ESD STM11.11 for thorough protection of your sensitive components.

Temperature Control Guidelines

Maintaining precise temperature control in ESD-protected areas is critical for effective static discharge prevention. You'll want to keep your temperature between 21°C and 24°C to guarantee ideal ESD protection. This range isn't arbitrary – it's backed by multiple standards, including MIL-STD-1695 and NASA's ESD Control Plan.

When you're managing your ESD bins, remember that temperature fluctuations can substantially impact your ESD protection measures. If you let temperatures vary too much, you'll risk compromising the surface resistivity of your materials and increasing static charge buildup.

Temperature stability directly affects the effectiveness of your ESD control strategies and the safety of your sensitive components.

You'll need to monitor your environment consistently to maintain these conditions. Don't overlook the relationship between temperature and humidity – they work together to create a safe ESD environment.

High temperatures combined with excessive humidity can increase your ESD risk. By keeping your temperature steady within the recommended range, you'll help preserve the conductivity of your ESD-safe materials and maintain the integrity of your ESD protection system.

Storage Environment Requirements

Several critical requirements shape the storage environment needed for ESD bins and sensitive electronic components. You'll need to maintain relative humidity between 40% and 60% to create a natural, conductive moisture film that enhances ESD protection.

This ideal range prevents chemical degradation while reducing the charging behavior of materials that can lead to dangerous discharges.

Consider these essential storage environment requirements:

- You must use ESD-safe storage solutions, including properly grounded shelving and cabinets, to create a controlled environment that dissipates static electricity effectively.

- You'll need to implement proper material handling practices, ensuring operators are grounded and using covered totes when moving sensitive components.

- Your facility should incorporate ESD floor protection and heel grounders to maintain continuous ESD protection during all handling operations.

- You'll want to establish consistent environmental controls, particularly in data centers and assembly lines, where equipment sensitivity demands rigorous ESD protection measures.

Maintenance and Inspection Methods

With proper storage conditions established, regular maintenance and inspection routines will keep your ESD bins functioning at peak performance.

You'll need to implement daily cleaning procedures using ESD-specific detergents and microfiber wipes to prevent contamination buildup.

Check your bins weekly for damage and verify that proper grounding connections remain intact.

Make sure you're monitoring humidity levels between 30% and 70%, and regularly inspect your ESD floor matting for wear from trolley wheels or footwear.

You'll want to examine storage packaging frequently to guarantee all items remain in shielded containers, removing any non-ESD materials immediately.

Document all your maintenance activities and keep detailed records of cleaning schedules, inspections, and any ESD events.

You should conduct monthly audits to verify that all control measures are working correctly. Don't forget to use your static-measuring devices to check surfaces regularly, and maintain your tacky mats at EPA entrances to control debris.

Train your staff quarterly on proper ESD handling procedures, and guarantee they're using appropriate grounding equipment like heel grounders and wrist straps.

Review your ESD control plan annually to maintain compliance with IEC-61340-5-1 standards.

Frequently Asked Questions

How Long Can ESD Bins Maintain Effective Moisture Control in Extreme Weather Conditions?

You'll find that ESD bins can maintain effective moisture control for 6-12 months in extreme weather, but it's dependent on your MVTR bag rating, desiccant quality, and how well you've sealed them.

Can Regular Plastic Bags Be Converted Into Moisture-Resistant ESD Storage Containers?

No, you can't convert regular plastic bags into ESD storage containers. They lack essential anti-static properties and electromagnetic shielding. You'll need specialized HDPE or PP containers that meet MIL-B-81705-B specifications for proper protection.

What Causes Moisture Indicator Cards to Fail Despite Proper Sealing Methods?

Your moisture indicator cards can fail due to component off-gassing, insufficient desiccant, material permeation, chemical degradation over time, and temperature fluctuations – even with proper sealing. Always verify desiccant quantities and material compatibility.

How Often Should Desiccants Be Replaced in Continuously Opened ESD Bins?

You'll need to replace desiccants more frequently in continuously opened bins, typically when humidity indicator cards show levels above 20%. Check cards daily and replace desiccants based on their readings.

Do Different Electronic Components Require Varying Moisture Control Levels Within ESD Bins?

Yes, you'll need different moisture control levels for your components. Sensitive semiconductors require 40-60% RH, while some coated components need 55-65% RH. Always check manufacturer specifications for specific requirements.

In Summary

You're now equipped to effectively manage moisture in your ESD bins through proper sealing, desiccant use, and environmental monitoring. By implementing these seven control methods consistently, you'll protect sensitive components from moisture damage while maintaining ESD safety. Don't forget to regularly inspect your storage systems and update your monitoring equipment. When you follow these guidelines, you'll guarantee maximum protection for your valuable electronic components.

Leave a Reply