When you're comparing static field meters, focus on these 7 key areas: measurement range and accuracy specs (typically 0-20kV with ±5% accuracy), power source and battery life (usually 20-40 hours on a 9V battery), display features and data logging capabilities, calibration requirements and maintenance needs, built-in safety systems, distance measurement capabilities (including scaling options), and industrial application compatibility. You'll want to check if the meter meets your specific industry standards, offers features like HOLD functions, and includes positioning guides for accurate readings. Understanding these comparison points will make your selection process much more strategic.

Measurement Range and Accuracy Specs

When evaluating static field meters, understanding their measurement ranges and accuracy specifications is essential for selecting the right device.

You'll find that the ETS 212 Static Field Meter provides the widest range, measuring from a few volts to several kilovolts per meter.

The Digital Static Field Meter models (TB-6567, TB-3029, TB-3090) offer a continuous range of 0 to ±19.99 kV, while the StopStatic meter splits its range into two distinct segments: 0~±1.49KV for low range and ±1.0KV~±20.00KV for high range.

In terms of accuracy, you'll need to take into account the varying specifications. The Digital Static Field Meter maintains a consistent ±5% accuracy across its entire range. Most meters feature a 3½-digit LCD display for precise real-time readings.

The StopStatic meter's accuracy varies depending on the range you're using: ±0.1KV for low range and ±1KV for high range, with an overall accuracy of ±10%.

While the ETS 212's exact accuracy percentage isn't specified, it typically operates within its stated tolerances.

If you need to measure beyond these ranges, you can adjust the measurement distance and apply a multiplier, though this may affect accuracy.

Power Source and Battery Life

Most static field meters rely on standard 9V alkaline batteries as their primary power source, offering anywhere from 20 to 40 hours of operation depending on the model.

Your device's battery life will vary based on whether you're using it continuously or intermittently, with continuous use typically reducing the operating time to around 20 hours. Many models feature automatic power shutoff after 20 minutes of inactivity to help conserve battery life.

When your battery voltage drops below 6.7V, you'll see a warning indicator on the display, signaling it's time for a replacement to maintain accurate measurements.

Battery Duration Specs

The power source specifications vary among static field meter models, with most units running on a standard 9 VDC alkaline battery. Different models offer varying battery life durations, with Desco models typically lasting longer than competitors.

You'll find that battery life generally ranges from 30 to 50 hours, depending on the specific model and usage patterns. The included 9 volt alkaline battery provides approximately 30 hours of continuous operation.

When comparing battery performance across different meters, consider these key specifications:

- Battery life monitoring shows "BAT" on the display when voltage drops below 6.7-7.4 volts, indicating it's time for replacement

- The Desco Digital Static Field Meter offers up to 50 hours of operation, while the Prostat PFM-711B provides approximately 20-30 hours

- You can extend battery life by using the HOLD button, turning off the device when not in use, and storing it properly

Environmental conditions and usage patterns impact battery duration substantially. To maximize your meter's battery life, you'll want to remove the battery during extended storage periods and limit continuous measurements.

When replacing batteries, always use fresh 9 VDC alkaline batteries and confirm proper installation by sliding the battery cover down to access the compartment.

Power Source Options

Building on the discussion of battery duration, understanding the broader range of power source options available for static field meters helps inform your equipment selection.

Most handheld static field meters rely on internal batteries for portability, though some models offer optional external power connections for extended use. You'll find that many devices come with rechargeable batteries and standard AC/DC adapters for convenient charging. The Haug Model 80302 is an example of a battery-powered unit built for rugged plant operations.

When comparing power sources, you'll notice high-end models typically use advanced lithium-ion batteries, while basic units operate with standard batteries. The charging methods vary, with options including USB ports and docking stations, and many devices feature rapid charging capabilities for minimal downtime.

If you're working in industrial settings, you'll want to evaluate meters with more robust power sources designed for demanding environments.

Your intended use should guide your power source selection. You'll need to weigh factors like portability requirements, operating environment conditions, and continuous operation needs.

While most handheld devices prioritize battery operation for mobility, some specialized models may use proprietary power sources that affect the unit's size and weight.

Display and Data Logging Features

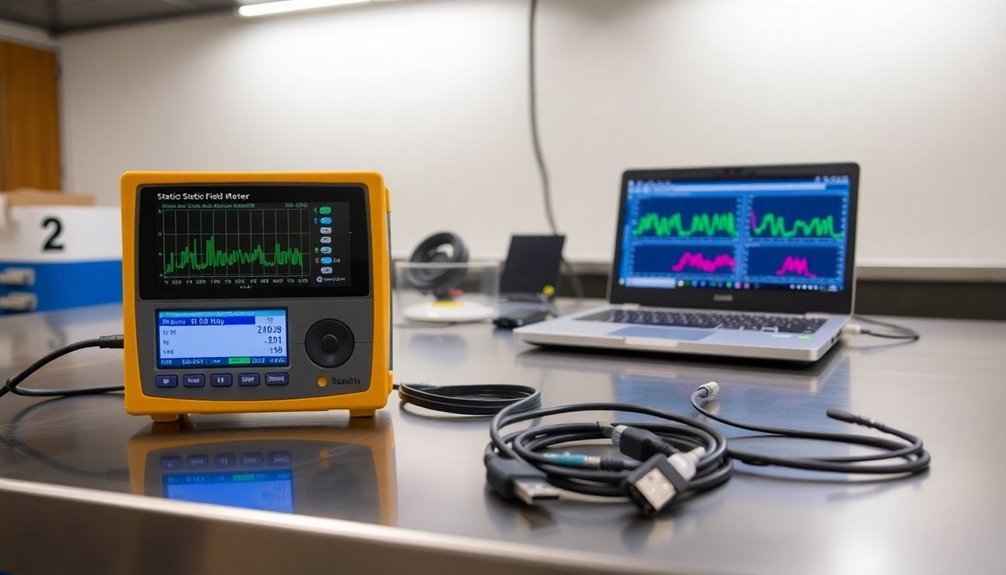

Modern static field meters incorporate extensive display and data logging features that enhance measurement accuracy and analysis capabilities. You'll find real-time measurements displayed in V/m or kV/m on clear digital screens, with LED guides helping you maintain proper positioning.

The HOLD function lets you freeze readings when needed, while multiple measurement modes including peak, peak hold, and average give you flexibility in data collection. Evaluating accuracy of measurement data requires careful analysis of all readings.

Data logging capabilities are essential for documenting and analyzing field measurements over time. You can store readings, generate detailed reports, and even connect to external devices like oscilloscopes for advanced analysis. The meters provide both digital and analog outputs, allowing you to process data according to your specific needs.

- Real-time display features with HOLD function and LED positioning guides guarantee accurate measurement capture

- Extensive data logging capabilities enable storage, report generation, and external device connectivity

- Multiple measurement modes and scalable readings accommodate various testing scenarios and requirements

When comparing static field meters, consider how the display features align with your measurement needs and whether the data logging capabilities meet your documentation requirements. The aspect ratio guidelines and scalability options help you maintain measurement accuracy across different distances and object sizes.

Calibration and Maintenance Requirements

To guarantee your static field meter meets NIST traceability standards and maintains measurement accuracy and compliance with industry regulations, several steps are necessary.

Your maintenance schedule should include regular cleaning of the aperture with instrument-grade air or isopropyl alcohol. This is crucial to ensure the sensor does not get impaired by foreign materials, which can generate undesired signals, offset, or drift, thereby affecting the accuracy and utility of the instrument.

Annual battery replacements are also essential. The battery should be replaced when the "BAT" indicator appears in the display or at least once a year. After changing the battery, you will need to re-zero the meter.

Calibration checks are another critical component. NIST traceable calibration ensures that your measurement instruments are calibrated to standards set by the National Institute of Standards and Technology (NIST), a recognized authority in metrology. When your instruments are NIST traceable, their accuracy can be traced back to NIST standards through a documented chain of calibrations. This traceability provides confidence in the reliability of your measurements, which is vital for quality assurance and compliance purposes.

When time is critical, you can take advantage of expedited calibration services that offer quick turnaround times while still maintaining full NIST certification. For example, services like those provided by Advanced NIST Calibration Services can quickly accommodate on-site equipment or equipment overnighted into their laboratory for rapid calibration and turnaround.

NIST Traceability Standards Required

For reliable static field measurements, maintaining NIST traceability is essential to guarantee your meter's accuracy and compliance with national standards. You'll need to confirm your fieldmeter's calibration can be traced back to NIST through a chain of intermediate calibrations and transfer standards. Most organizations follow a one-year recalibration schedule similar to standard multimeters.

When selecting a calibration service, you should understand the difference between NIST traceability and ISO 17025 accreditation. While NIST traceability confirms your measurements link to national standards, ISO 17025 certification provides additional assurance of the calibration lab's competence and quality systems.

Your fieldmeter's calibration should include comparison readings against known electric field values, achieved by dividing applied voltage by separation gap distance.

You'll need to verify calibration across both polarities and multiple ranges, typically from 25% of the most sensitive to 25% of the least sensitive range.

Look for a calibration provider who uses appropriate transfer standards and maintains proper documentation of the calibration chain.

The calibration process requires careful attention to environmental factors, including dust and static charge interference.

You'll want to establish a recertification schedule based on your meter's drift characteristics and your accuracy requirements.

Regular Maintenance Schedule Essentials

Building on proper NIST traceability, a thorough maintenance schedule keeps your static field meter operating at peak performance. You'll need to follow specific maintenance requirements, including annual calibration by the factory and battery replacement when the "BAT" indicator appears or annually for chargers.

When maintaining your meter, remember there are no user-serviceable parts, and any unauthorized tampering voids the warranty.

You'll need to zero the meter at first use and after replacing the 9V alkaline battery. Keep the area around the aperture clean using low-pressure instrument-grade air or technical-grade isopropyl alcohol to guarantee accurate readings.

You must be properly grounded using a wrist strap or foot grounding device when operating the meter. Don't subject the meter to drops or impacts, as this will void your warranty and require factory recalibration.

Remove batteries during extended storage periods to prevent damage. If your meter requires repair, it'll need recalibration afterward.

The maintenance frequency should align with how critical your ESD-sensitive items are. For top performance, your meter should maintain its ±5% measurement accuracy across its full range of 0 to ±20kV/inch.

Expedited Calibration Service Options

When time is critical, several expedited calibration service options are available for your static field meter. You'll find various turnaround times ranging from same-day service to four-day processing, each with corresponding expedite fees.

Same-day calibration typically costs around $200 per unit, while overnight service runs about $140, and two-day service is approximately $115.

Leading calibration providers like ESSCOLAB, Yotta Volt, and Accura Calibration offer these expedited services, guaranteeing your equipment maintains NIST traceability standards. You'll need to provide your meter's manufacturer details, model number, and serial number when scheduling expedited service.

- Same-day service with pickup and delivery is ideal for urgent production requirements

- Next-on-bench primary standard calibration provides premium service for critical applications

- Four-day service offers a cost-effective balance between speed and economy

Remember that not all equipment qualifies for expedited service, particularly if new data sheets need creation. Environmental controls and certification requirements may also affect turnaround times. The four-day expedited option offers significant savings at just $60 per calibration.

For successful expedited calibration, you'll need to give advance notice and guarantee your service provider has the proper accreditation for your specific meter type.

Safety and Protection Systems

Safety features are paramount in modern static field meters, with multiple protection systems working together to safeguard both users and equipment. You'll find thorough protection through features like overload prevention and ESD safeguards, particularly in devices like the ETS 212. These meters incorporate proper grounding connections and alarm functions to alert you when static levels become dangerous. The ability to measure in ionized air environments makes these meters especially valuable for industrial operations.

| Safety Feature | Your Benefit |

|---|---|

| Overload Protection | Prevents device damage during high field measurements |

| ESD Protection | Protects you and the meter from electrostatic discharge |

| Grounding Connections | Guarantees your safety through proper electrical paths |

| Alarm Functions | Alerts you when static levels exceed safe thresholds |

| Calibration Certificates | Gives you confidence in measurement accuracy |

You'll appreciate the attention to user safety in modern static meters, which integrate multiple protection systems. The ACL 450B, for instance, comes with traceable calibration certificates and CE marking, confirming its compliance with safety standards. When you're working in ionized environments or sensitive areas, these protection systems become vital for maintaining both accurate measurements and workplace safety. The combination of safety features and compliance standards guarantees you're well-protected while conducting static field measurements.

Distance and Positioning Capabilities

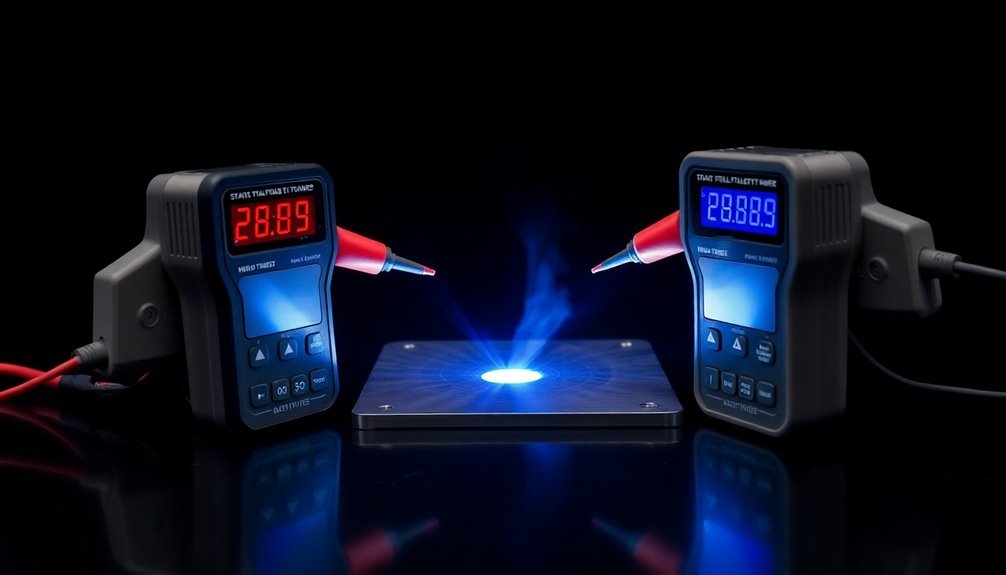

Modern static field meters excel in their distance and positioning capabilities, offering versatile measurement options that complement their safety features.

You'll find typical measurement ranges from ±3,000 V to ±30,000 V, with readings possible at both 1-inch and 4-inch distances from the target object. For maximum accuracy, you'll need to maintain proper aspect ratios, guaranteeing your measured object is at least a 3-inch square when measuring at 1-inch distance.

To achieve accurate measurements, you must guarantee proper grounding through either your hand or the provided ground cord. Many meters now include helpful positioning aids:

- LED rangefinder systems for precise distance maintenance

- HOLD functions to freeze measurements for easier reading

- Digital and bar graph displays with +/- indicators

You can scale your measurements by multiplying the meter reading by the distance from the object, though accuracy typically ranges from ±5% to ±10% of the displayed value. Remember that increasing distance affects accuracy and requires appropriate measurement scale adjustments.

When working in manufacturing areas, you'll appreciate that these meters can take readings from both 1-inch and 4-inch distances, offering flexibility for various applications.

Industrial Application Compatibility

Static field meters seamlessly integrate into diverse industrial environments, serving critical roles across electronics manufacturing, printing, packaging, and textile operations. You'll find these devices particularly valuable when working with ESD-sensitive components, as they're designed to protect delicate electronic elements like CMOS chips and MOSFETs during handling and assembly processes.

When you're evaluating industrial compatibility, look for meters that offer chopper-stabilized circuitry and pulsing-bullseye indicators, as these features guarantee accurate measurements in challenging industrial settings.

You'll want to verify that your meter meets relevant compliance standards, including ANSI/EOS/ESD requirements and CE certification, depending on your industry's specific needs.

For specialized applications, you should consider models like the 450B Digital Static Locator if you're working in ionized environments. The HOLD function proves especially useful when you need to capture readings in hard-to-reach areas or monitor transient charges.

Whether you're processing plastics, managing converting operations, or overseeing quality control in electronics manufacturing, you'll need a meter that's certified for your specific industrial application and can accurately measure both conductive and insulative materials.

Frequently Asked Questions

Can Static Field Meters Be Used in Wet or Humid Environments?

You shouldn't use static field meters in wet environments, as moisture can damage them. While you can use them in humid conditions up to 70% RH, they'll work best in drier environments.

How Long Does It Typically Take to Train Staff on Meter Usage?

You'll typically need 2-4 hours for basic training, but it can take 1-2 days for thorough understanding. Prior experience with similar devices and hands-on practice will substantially reduce your learning time.

What Happens if Measurements Are Taken Through Glass or Plastic Barriers?

You'll get inaccurate readings when measuring through glass or plastic barriers. These materials distort the electrostatic field and interfere with proper meter calibration. It's best to take direct measurements without barriers.

Are There Specific Storage Requirements for Static Field Meters?

You'll need to store your static field meter at 0-40°C with 20-70% humidity. Remove batteries for long storage, avoid chemicals and vibrations, and keep it away from flammable materials and condensation-prone areas.

Can Multiple Meters Be Used Simultaneously in Close Proximity?

You shouldn't use multiple static field meters simultaneously in close proximity. They can interfere with each other's readings. It's best to operate one device at a time to maintain measurement accuracy.

In Summary

You'll make a better decision comparing static field meters by evaluating these seven key aspects. Focus on finding a meter that matches your accuracy needs, provides reliable power, offers clear data display, maintains calibration stability, includes safety features, works at your required distances, and suits your industry requirements. Consider these factors together rather than individually to select the most effective meter for your application.

Leave a Reply