Pink anti-static foam sheets protect your electronic components from static discharge and physical damage during storage, transport, and handling. You'll want to select the right thickness (1/8" to 2") and density (1-2 lb/cubic foot) based on your components' needs. Cut or customize the foam to create precise-fitting trays, wraps, or inserts for your specific electronics. Always handle the foam in a clean, dry area while wearing protective gloves to prevent contamination. Remember to store sheets flat in a temperature-controlled space and replace them every six months as their anti-static properties degrade. There's much more to discover about maximizing these versatile protective materials.

What Are Pink Foam Sheets

Protecting sensitive electronics requires specialized materials, and pink foam sheets are specifically designed for this purpose. These sheets are made from anti-static polyethylene foam with a distinctive pink color that makes them easily identifiable in manufacturing and packaging environments. The material is manufactured by combining PE raw materials and additives to create its protective properties.

You'll find these foam sheets available in various thicknesses, ranging from 1/8" to 2", and they come in both 1lb and 2lb density options.

The closed-cell structure of the foam provides excellent protection against shock and water damage while maintaining anti-static properties that help prevent electrostatic discharge.

When you're working with electronic components, you'll appreciate that these RoHS and REACH approved sheets can be customized to your specific needs. You can cut, split, laminate, or thermoform them to create the perfect protective solution for your electronics.

However, you should be aware that pink foam sheets have a limited shelf life due to the gradual degradation of their anti-static properties. The foam contains special surfactants that help dissipate electrostatic charges, but these properties diminish over time, making them unsuitable for long-term storage solutions.

Types of Anti-Static Foam

When protecting your electronics, you'll find that pink anti-static foam sheets offer specific resistance levels between 10^9 and 10^12 ohms, making them suitable for basic component storage. These foams require static shielding bags for complete ESD protection during transport.

The foam's density directly impacts its protective capabilities, with denser foams providing better cushioning and static control for sensitive devices.

You'll need to match your protection requirements to the right type of anti-static foam, considering whether you need rapid discharge (conductive black foam), controlled dissipation (static dissipative foam), or basic static prevention (pink anti-static foam).

Pink Anti-Static Sheet Properties

Anti-static foam sheets come in several distinct varieties, with ESD EPE foam being one of the most common types you'll encounter.

When you're working with pink anti-static foam sheets, you'll find they're made from expandable polyethylene with anti-static properties added through a special liquid treatment. These sheets typically have a surface resistance ranging from 10^8 to 10^11 and feature a closed cell structure that enhances their protective capabilities.

You'll notice that pink anti-static foam sheets are highly versatile and offer multiple beneficial properties. They're thermoformable, allowing you to mold them into custom shapes for specific components. The material is ideal for packaging sensitive electronics during storage and transportation.

The material is non-corrosive, non-toxic, and odorless, making it safe for use with sensitive electronics. You can expect excellent chemical resistance, as these sheets effectively resist moisture, fungi, and various chemicals.

When selecting pink anti-static foam, you'll be working with a material that typically has a density of around 1.7 lb for EPE foam. Keep in mind that the anti-static properties have a limited lifespan of approximately six months, so you'll need to plan for replacement or renewal of the material accordingly.

Foam Density Matters Most

Foam density stands as the most critical factor when selecting anti-static materials for electronics protection. When you're working with sensitive electronic components, you'll need to think about densities ranging from 2 to 6 pounds per cubic foot (pcf) to guarantee proper protection and static dissipation. The volume resistivity range of 10^10 to 10^12 ohms/cms helps ensure proper static control.

For most electronics applications, you'll encounter three main types of anti-static foam: conductive, static dissipative, and pink anti-static foam. Conductive foams offer the quickest static charge dissipation with resistance values of 10^3-10^5, making them ideal for highly sensitive components.

If you're working with circuit boards during transit, you'll want to choose low-density conductive foam for its superior cushioning properties.

High-density conductive foam works best when you need to insert components with pins or legs, as it prevents potential differences between the pins.

Pink anti-static foam, while common, contains additives that degrade over time, so you'll need to think about its limited shelf life.

When selecting your foam density, think about your specific application requirements, component sensitivity, and environmental conditions. Remember that higher density doesn't always mean better protection – it's about matching the right density to your specific needs.

Choosing Right Protection Level

Selecting the right protection level for your electronic components requires understanding three distinct types of anti-static foam. You'll need to choose between conductive, anti-static, and static dissipative foam based on your specific needs.

If you're handling highly sensitive electronics that need complete shielding, you'll want conductive foam. It's black in color, made from carbon-filled polyethylene, and provides Faraday cage protection with a surface resistance under 10^6 ohms. You won't need an additional static shielding bag with this option.

For general protection, pink anti-static foam might be your best choice. It prevents static buildup through friction and has a surface resistance between 10^9 and 10^12 ohms. However, you'll need to pair it with a static shielding bag for complete protection. Regular quality inspections of the foam will help maintain its protective properties over multiple uses.

If you need a middle-ground solution, consider static dissipative foam. It offers balanced protection with a surface resistance of 10^5 to 10^9 ohms and allows for gradual static discharge. You can find it in both black and pink varieties, making it ideal for work-in-progress situations where controlled discharge is important.

Remember to verify that your chosen foam meets EIA-541 Packaging Material Standards for ESD-sensitive items.

Selecting the Right Foam Sheet

When choosing the right foam sheet for your electronics, you'll need to take into account several critical factors that affect protection and performance. Think about the length of storage, environmental conditions, and the specific cushioning requirements of your electronic components.

| Selection Factor | What to Think About |

|---|---|

| Storage Duration | Choose polyethylene for long-term storage, polyurethane for short-term |

| Environmental Exposure | Select closed-cell foam for moisture protection, chemical resistance |

| Cushioning Needs | Pick convoluted sheets for extra padding, flat sheets for basic protection |

For moisture-prone environments, opt for closed-cell polyethylene foam, as it'll protect against water damage and prevent mold growth. If you're shipping delicate electronics that need extra cushioning, think about convoluted sheets that provide superior shock absorption. For components requiring precise fits, you can request custom cuts to match your specifications.

Don't forget to factor in the weight considerations – lightweight foam helps reduce shipping costs while maintaining protection levels. Consider that durable and resilient polyethylene materials provide excellent longevity for your storage needs. If you're handling particularly sensitive electronics, choose foam sheets with anti-static properties to prevent electrical damage. Remember that pink and black color options are available, though both provide the same level of protection for your electronics.

Safety Features and Protection

Pink foam sheets protect your electronics with multiple safety features you'll need to understand.

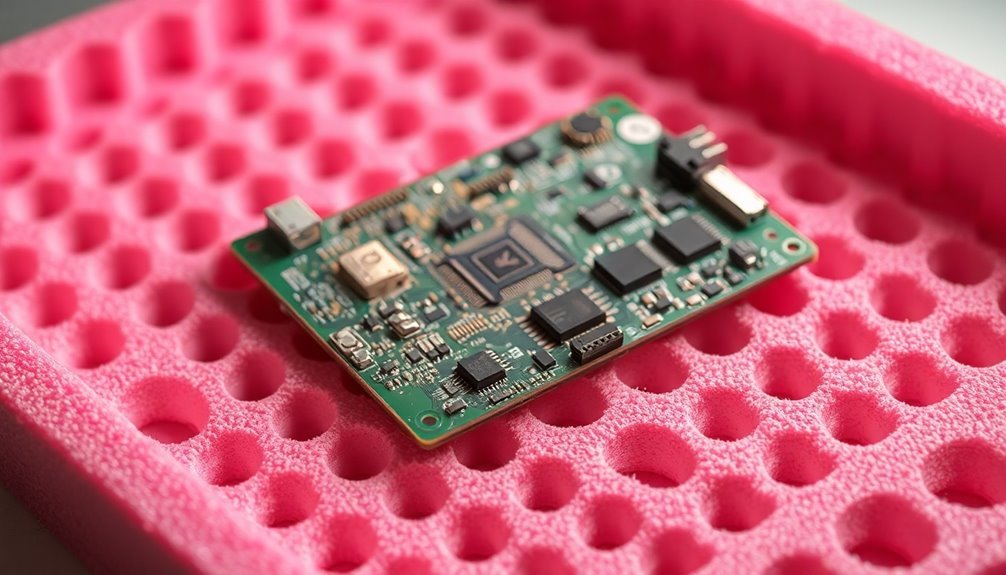

The material's ESD polyethylene composition dissipates static charges through its surface resistance of 10^6-10^11 Ohm/sq, while its closed-cell structure absorbs impacts and vibrations during transport.

You'll also benefit from the foam's moisture resistance properties, which prevent water damage and inhibit the growth of bacteria and mold that could harm your electronic components. The foam provides heat insulation protection that helps maintain stable temperatures for sensitive electronic devices.

Static Protection Measures

To protect sensitive electronic components, anti-static pink foam sheets incorporate specialized additives during manufacturing, including low molecular weight fatty acids based on amides or amines. These surfactants act as mobile surface modifiers that temporarily alter the friction properties between surfaces, helping to prevent tribo charging. Regular foam testing is necessary to ensure continued efficacy and compliance with ESD standards.

You'll find that pink anti-static foam meets ANSI/ESD S541 standards for ESD-protected areas (EPA), making it suitable for cushioning and packaging sensitive electronics. The foam's surface resistance typically ranges between 10e5-10e11 ohms, providing effective static dissipation while maintaining good thermal stability and chemical resistance.

When you're working with electronic components, you can use this foam for blocking, bracing, wrapping, and cushioning. It's available in various forms, including egg-crate patterns, flat sheets, rolls, and custom die-cut inserts.

However, you'll need to be aware that the anti-static properties aren't permanent and will degrade over time. Once the foam reaches its shelf life, it can become harmful to your manufacturing environment and sensitive components, so you'll need to replace it periodically to maintain proper ESD protection.

Impact Resistance Properties

From a safety perspective, anti-static pink foam sheets deliver exceptional impact resistance through their closed-cell structure and specialized material composition. The material's tensile strength of up to 300MPa and elongation capacity of up to 50% provide robust protection against physical damage during handling and transportation of sensitive electronic components.

You'll find these foam sheets particularly effective at cushioning your electronics due to their shockproof properties and consistent shape retention. The closed-cell structure guarantees reliable protection while resisting water, bacteria, and mold, making them ideal for both short-term and long-term applications.

- You can easily customize the foam's thickness and shape to match your specific protection requirements

- The material won't corrode or contaminate your electronic components

- Impact resistance remains stable across varying temperatures with less than 2% thermal variation

- The non-sloughing properties prevent particle shedding that could damage sensitive equipment

- You can thermoform the sheets to create custom-fit protective casings

The foam's combination of physical durability and anti-static properties makes it an excellent choice for protecting electronic components in manufacturing, storage, and transportation environments where impact resistance is vital.

Moisture Prevention Solutions

Building on its impact resistance capabilities, anti-static pink foam sheets excel at moisture prevention through their specialized closed-cell structure.

When you're protecting sensitive electronics, you'll find that these sheets create an effective barrier against humidity and condensation. The closed-cell design prevents water absorption, while the non-corrosive and non-contaminating properties safeguard your components remain safe in diverse environmental conditions.

You'll benefit from the foam's resistance to mold and mildew, making it ideal for long-term storage solutions. The material's non-dusting and non-sloughing characteristics mean you won't have to worry about particulate contamination. Since the foam meets RoHS and Reach standards, you're assured of its safety for electronic applications.

To maximize moisture protection, you can customize the foam sheets to your specific needs. They're available in various densities and thicknesses, and you can easily cut them to create precise fits for your components.

When storing or transporting electronics, position the foam to create complete enclosures, providing thorough protection against moisture. The anti-static properties work alongside the moisture resistance to provide dual protection for your sensitive electronic items.

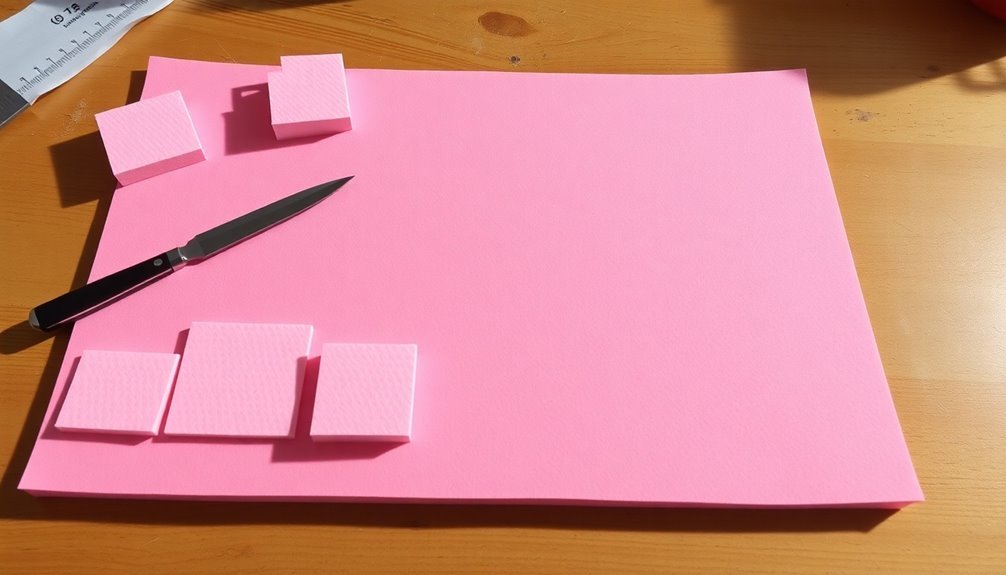

Cutting and Customizing Pink Foam

Working with pink foam requires specific cutting and customization techniques to achieve professional results. You'll need a utility knife for initial cuts and a hot wire cutter for precise shaping. To create thicker structures, layer multiple sheets using Elmer's glue, but remember to complete your cuts before the glue sets to prevent wire damage.

When cutting and customizing your pink foam, consider these essential techniques:

- Use a utility knife to create rough guide cuts before moving to more precise tools.

- Control the hot wire cutter with a foot pedal for better precision and consistent results.

- Apply 120-grit sandpaper to smooth rough edges after cutting.

- Create curves by taping the outer surface or cutting V-shapes on the inner side.

- Follow the foam's grain direction for ideal bending and cutting results.

For complex projects, you'll want to start with larger dimensions and work your way down to smaller pieces. Remember to maintain proper safety measures by keeping your hands away from blades and cutting wires.

Choose your foam thickness based on your project's specific requirements, and use pattern templates when you need detailed surface designs.

Proper Storage and Handling Methods

Once you've cut and customized your pink foam sheets, proper storage and handling will protect your investment and maintain the material's integrity.

When handling the sheets, always work in a clean, dry environment and wear protective gloves to prevent contamination and static buildup. Don't touch the foam surface directly, and use non-static wrapping materials when moving sheets.

Store your foam sheets flat in a well-ventilated, temperature-controlled area away from direct sunlight and heat sources. You'll want to keep them in their original packaging or airtight containers to prevent dust and debris accumulation.

If you're storing sheets long-term, rotate them periodically to prevent compression and deformation.

Safety should be your priority during handling and storage. Guarantee proper ventilation in your work area to avoid inhaling particles or fumes, and keep foam sheets away from flammable materials and open flames.

You'll need to regularly inspect stored sheets for signs of damage or deterioration. For electronics packaging applications, consider using climate-controlled storage to maintain ideal conditions.

Don't forget to label your stored foam sheets with dates and contents for easy identification and inventory management.

Common Uses in Electronics

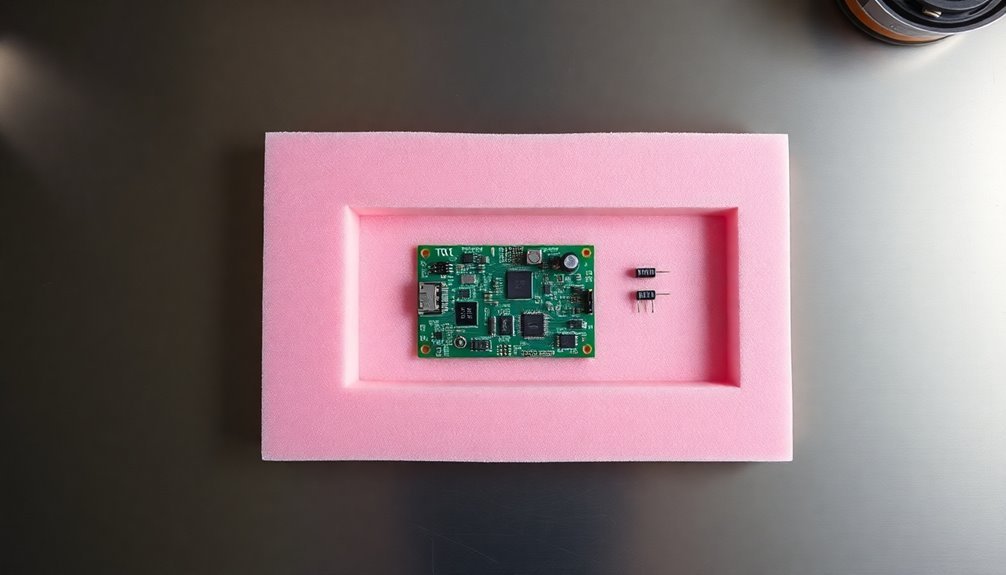

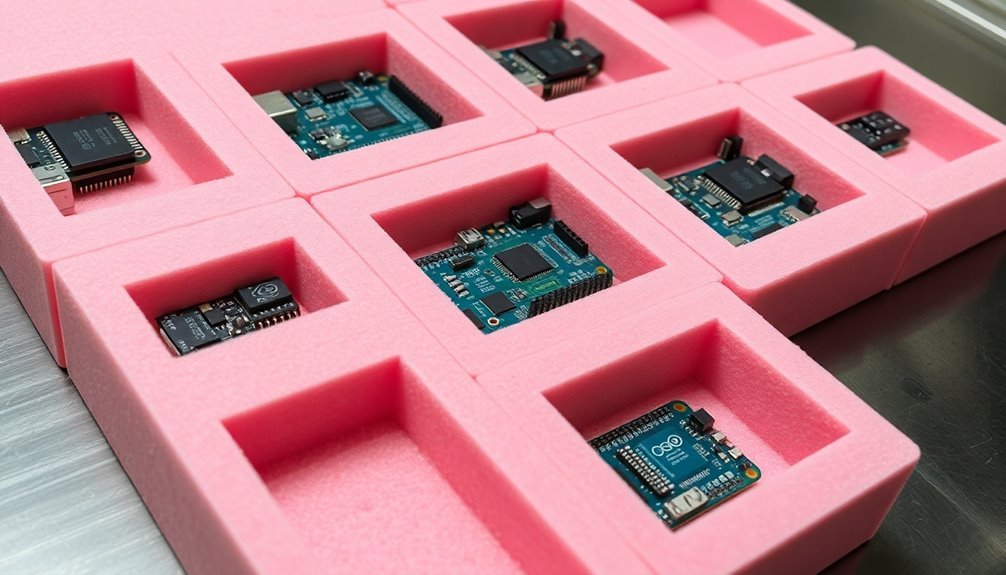

As electronics become increasingly sensitive to static electricity, pink foam sheets serve as an essential protective material across various applications. You'll find these versatile sheets particularly useful for protecting circuit boards, CPUs, and other ESD-sensitive components during handling, storage, and transportation.

When working with electronic devices, you can utilize pink foam sheets in several ways:

- Package delicate components in customized die-cut foam inserts for precise protection

- Wrap sensitive circuit boards during maintenance or assembly procedures

- Line storage containers and workbenches to create static-safe environments

- Create temporary protective layers during equipment installation

- Fashion custom-sized padding for shipping electronic components

You'll appreciate that pink foam sheets come in both polyethylene and polyurethane varieties, offering different levels of protection based on your needs.

The closed-cell polyethylene foam provides excellent durability and moisture resistance, while the lighter polyurethane foam works well for smaller, more sensitive items.

These materials are non-abrasive and won't damage delicate surfaces, making them ideal for displays, LEDs, and medical equipment.

They're also cost-effective and environmentally friendly, as they're recyclable and free from harmful chemicals.

Best Practices for Packaging

Several critical practices guarantee effective packaging of electronic components with pink foam sheets. You'll need to confirm your packaging setup meets essential guidelines, including the use of materials that generate minimal static charges and provide proper electrostatic discharge shielding.

When working with pink foam sheets, you should customize them to fit your specific requirements while maintaining compliance with ANSI/ESD standards.

For maximum protection, you'll want to cut and shape the foam using appropriate techniques like die-cutting, and when joining pieces, use non-toxic adhesives with proper clamping methods. It's vital to select the right density of foam for your application, taking advantage of its closed-cell structure and dissipative properties.

Remember that these sheets have a limited shelf life, so you'll need to monitor their condition regularly.

Store your foam sheets in a controlled environment and handle them carefully to maintain their protective properties. You should conduct periodic testing to verify the foam's static dissipative effectiveness.

When the foam shows signs of degradation or has reached the end of its useful life, dispose of it properly and replace it with fresh material.

Durability and Lifespan Expectations

Pink foam sheets have specific durability limitations you'll need to understand for effective electronics protection. The most critical factor is their shelf life for anti-static properties, after which they can't reliably protect your electronics from ESD damage.

While these sheets offer excellent cushioning and shock absorption, they're particularly vulnerable to environmental factors like moisture and temperature, which can compromise their protective qualities.

You'll want to keep track of these key durability aspects:

- Monitor the expiration date carefully – once expired, the foam loses its ESD protection

- Store in controlled environments away from moisture and extreme temperatures

- Check regularly for signs of degradation or physical damage

- Use only within the recommended timeframe

- Consider alternatives for long-term storage solutions

When comparing pink foam to other materials, you'll find it's specifically designed for short-term ESD protection rather than long-lasting insulation. While materials like spray foam can last 80-100 years, pink foam's limited lifespan makes it best suited for temporary electronics packaging.

For long-term storage or shipping needs, you'll need to implement a quality program that includes regular material verification and replacement schedules.

Cost and Purchasing Considerations

When evaluating foam sheets for electronics protection, you'll find significant cost variations based on material type and purchasing volume. While polyethylene foam offers a cost-effective solution for basic needs, polyurethane foam's superior cushioning properties come at a higher price point but provide better protection for sensitive components.

You'll save money by purchasing standard sizes in bulk, as suppliers typically offer volume discounts and free shipping on large orders. For custom requirements, you can expect additional charges for specialized cutting services and adhesive backing options, though these costs may be justified for specific packaging needs.

| Feature | Polyethylene | Polyurethane |

|---|---|---|

| Cost Level | Lower | Higher |

| Bulk Discounts | Available | Limited |

| Custom Cutting | Additional fee | Additional fee |

| Adhesive Options | Standard pricing | Premium pricing |

| Shipping Costs | Often free for bulk | Varies by weight |

For the most cost-effective purchasing strategy, consider working directly with suppliers like Correct Products or ESDGoods. They'll help you evaluate whether standard sizes meet your needs or if custom solutions are necessary. You can also explore online marketplaces like Foambymail for competitive pricing and detailed product specifications.

Frequently Asked Questions

Can Pink Anti-Static Foam Be Reused Multiple Times for Different Electronic Components?

You can reuse pink anti-static foam, but it's not recommended. The foam's electrical properties decay after six months, and repeated use degrades its ESD protection and cushioning effectiveness for your electronics.

Do Pink Foam Sheets Lose Their Anti-Static Properties When Exposed to Sunlight?

Yes, your pink foam sheets will lose their anti-static properties faster when exposed to sunlight. UV radiation accelerates the degradation of the foam's protective surfactants, so you'll want to store them away from sunlight.

Are Pink Foam Sheets Safe to Use With High-Temperature Electronic Devices?

You shouldn't use pink foam sheets with high-temperature electronics as they're not specifically designed for heat resistance. Consider specialized thermal insulation foams like POLYDAMP Melamine or Polyimide foam for better protection instead.

How Do You Properly Dispose of Used Pink Anti-Static Foam Sheets?

You'll need to take your used pink anti-static foam sheets to specialized recycling facilities. Don't throw them in regular trash. Make certain they're clean, dry, and free of contaminants before recycling through licensed carriers.

Can Pink Foam Sheets Be Used Alongside Other Types of Protective Packaging?

Yes, you can combine pink foam sheets with other protective materials like bubble wrap, corrugated boxes, and foam inserts. They'll work especially well with polyurethane foam for enhanced cushioning and protection of your items.

In Summary

You'll find pink anti-static foam sheets are essential for protecting your sensitive electronic components during storage and shipping. By choosing the right thickness, cutting accurately, and following proper handling procedures, you'll extend the life of your equipment while preventing costly damage from static discharge. Remember to store your foam sheets in a climate-controlled environment and replace them when they show signs of wear.

Leave a Reply