To protect circuit boards with foam packaging, you'll need ESD-safe foam materials like anti-static polyethylene or conductive polyurethane foam. Select foam with appropriate resistance values (10^3-10^11 ohms) that complies with ANSI/ESD S20.20 standards. Create custom-cut inserts that match your board's exact dimensions, ensuring proper cushioning and support points. Use anti-static pink foam for short-term storage or carbon-infused conductive foam for long-term protection. Store boards in grounded containers with foam dividers, and maintain proper environmental conditions. The right combination of foam type, design, and handling practices will maximize your circuit boards' protection throughout their lifecycle.

Understanding ESD Foam Properties

Selecting the right ESD foam starts with understanding its fundamental properties. You'll find that ESD foam comes in various materials, including polyurethane, ethylene vinyl acetate, and polyethylene, each offering different levels of protection.

These materials can feature either open-cell or closed-cell structures, which directly affect their protective capabilities. The ANSI/ESD S20.20 standards must be met by all foam types to ensure effective ESD protection.

When you're examining ESD foam options, pay attention to their resistance values. Conductive foam measures between 10^3-10^5 ohms, black anti-static foam ranges from 10^6-10^9 ohms, and pink static dissipative foam falls between 10^8-10^11 ohms. The color coding isn't just aesthetic – it helps you identify the foam's specific properties and intended use.

You'll need to take into account the foam's density and composition, as these factors determine its ability to cushion and protect your circuit boards. The presence of conductive fillers and antistatic agents enhances the foam's ability to dissipate static charges effectively.

Remember that environmental conditions like humidity and temperature can affect the foam's performance, so you'll want to choose a material that maintains its protective properties under your specific storage or shipping conditions.

Types of Protective Foam Materials

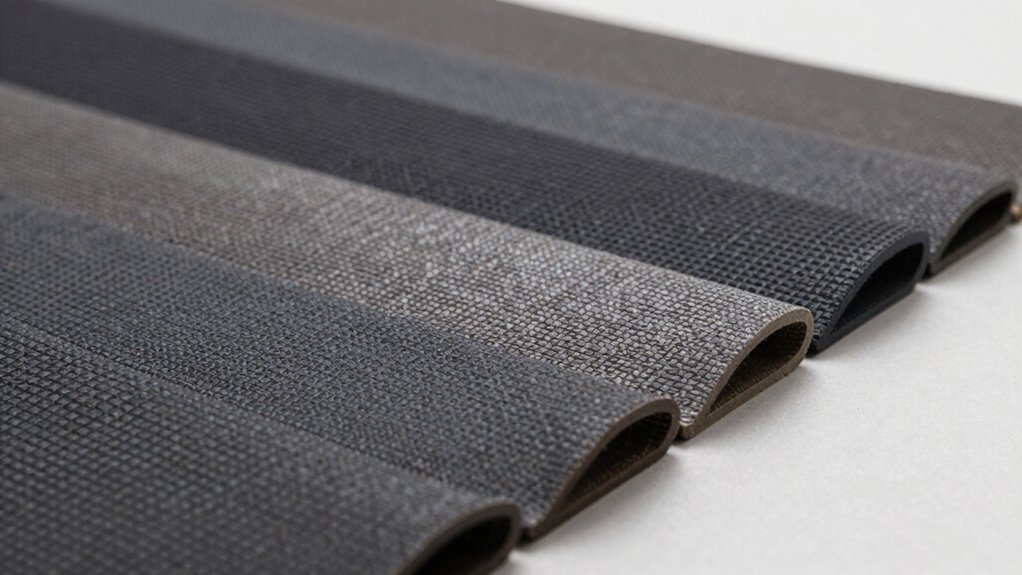

In accordance with industry standards, protective foam materials for circuit boards fall into four main categories: antistatic, conductive, polyethylene, and polyurethane foams.

Antistatic foam is designed to dissipate electrostatic charges safely. You'll find it's often colored pink for easy identification and can be custom-cut to fit your specific needs. These materials are extensively used in tailored packaging solutions to meet unique application requirements.

It's made from materials like polyethylene or polyurethane with added antistatic agents to prevent ESD damage.

Conductive foam offers superior electrical protection and EMI shielding through its carbon-infused composition. You'll want to use this type for long-term storage solutions, as it provides excellent static charge dissipation and thermal conductivity.

Polyethylene foam delivers exceptional shock absorption and vibration damping. Its closed-cell structure makes it moisture-resistant and chemically inert, making it ideal for protecting heavier electronic components.

You can get it in various densities and both non-crosslinked and cross-linked versions.

Polyurethane foam features an open-cell structure that's perfect for delicate electronics. While it's often used for short-term applications due to its cost-effectiveness, you can also find it in antistatic or conductive versions for enhanced protection.

It's particularly suitable for packaging circuit boards that require gentle cushioning.

Custom Foam Insert Design

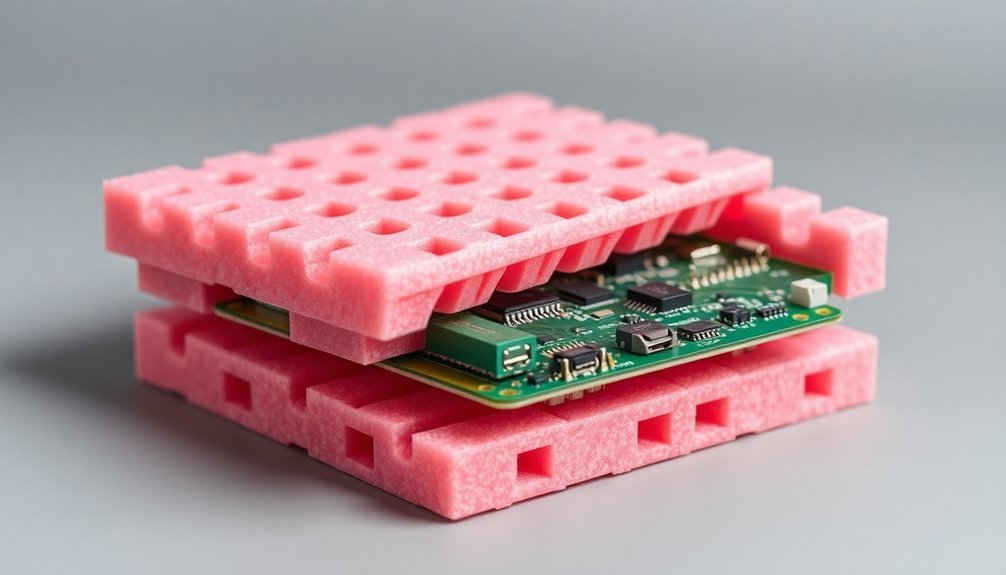

Once you've identified the right foam material for your circuit boards, the next step involves creating custom foam inserts that perfectly match your components. You'll need to start with CAD design software to create precise measurements and specifications that account for your board's dimensions, weight distribution, and fragile areas. Reliable foam fabricators can deliver designs in 3-5 days for your review and approval.

During the design process, you'll want to factor in several critical elements. Consider how the circuit board will be handled and transported, as this affects the cushioning requirements.

You'll also need to evaluate the positioning needs to guarantee the board remains secure within the insert. If you're working with sensitive electronic components, don't forget to incorporate electrostatic protection into your design.

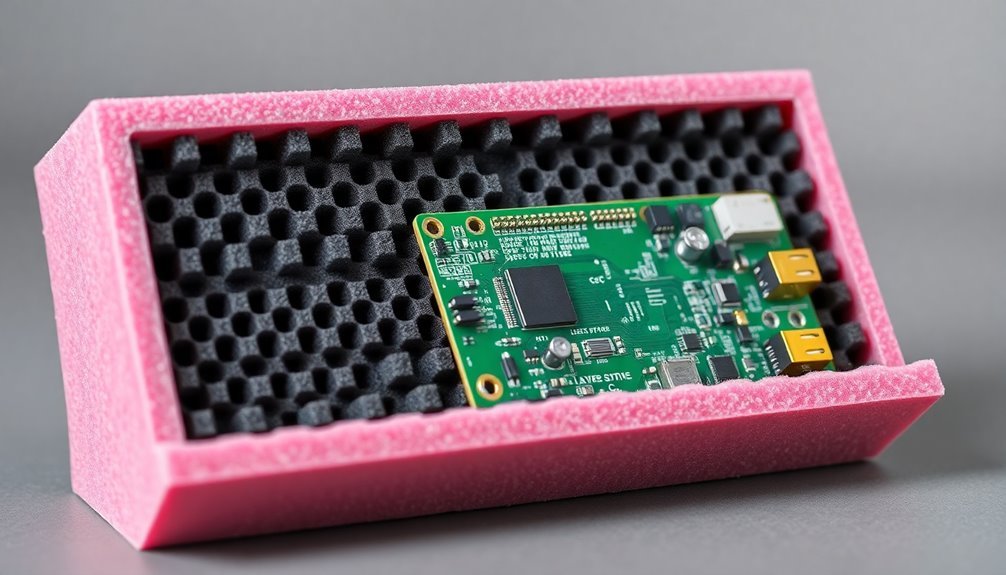

Picture a snug, custom-cut cavity that cradles your circuit board like a puzzle piece, with strategically placed support points.

Envision raised cushioning areas that protect delicate components while maintaining proper airflow.

Think of precisely engineered corners and edges that absorb shock and prevent movement during transit.

Test your design through prototyping and sampling before finalizing the production. This validation step guarantees your custom foam insert meets all protection requirements and performs as intended under real-world conditions.

Static Protection Best Practices

Static-sensitive circuit boards require thorough protection strategies to prevent costly damage from electrostatic discharge. When handling and packaging your boards, you'll need to implement multiple layers of static protection to safeguard their safety during storage and transport.

Start by using anti-static foam packaging materials that provide both physical cushioning and ESD protection. Latent defects can develop over time even from minor static exposure, leading to eventual component failure.

You'll want to safeguard that all storage containers and handling equipment are properly grounded to prevent static build-up. Don't stack circuit boards or place heavy objects on top of them, as this can cause both physical damage and increase static risk.

To optimize your static protection strategy, maintain low-impedance paths to ground throughout your handling areas. You should equip your workspace with surge protectors and voltage regulators, while keeping all electrical equipment properly grounded.

When designing your storage solution, incorporate separate ground planes that connect to earth ground for effective ESD dissipation.

Remember to regularly inspect all grounding connections and protective measures. Apply appropriate protective coatings to shield your boards from moisture, dust, and chemicals.

Store your circuit boards in anti-static bags before placing them in foam packaging for an additional layer of protection.

Transport and Storage Solutions

Professional transport and storage solutions require carefully selected materials and containers to protect your circuit boards throughout their handling lifecycle.

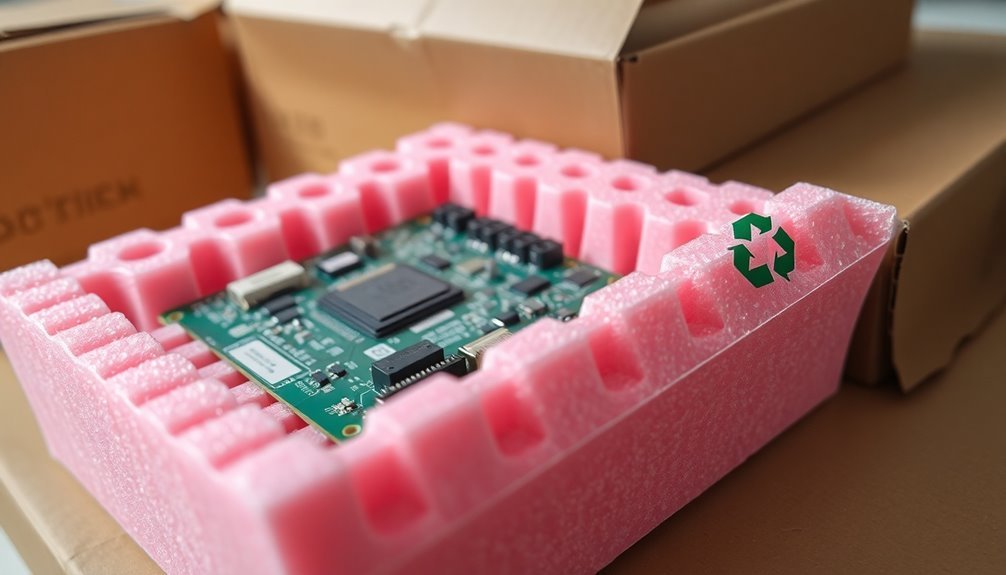

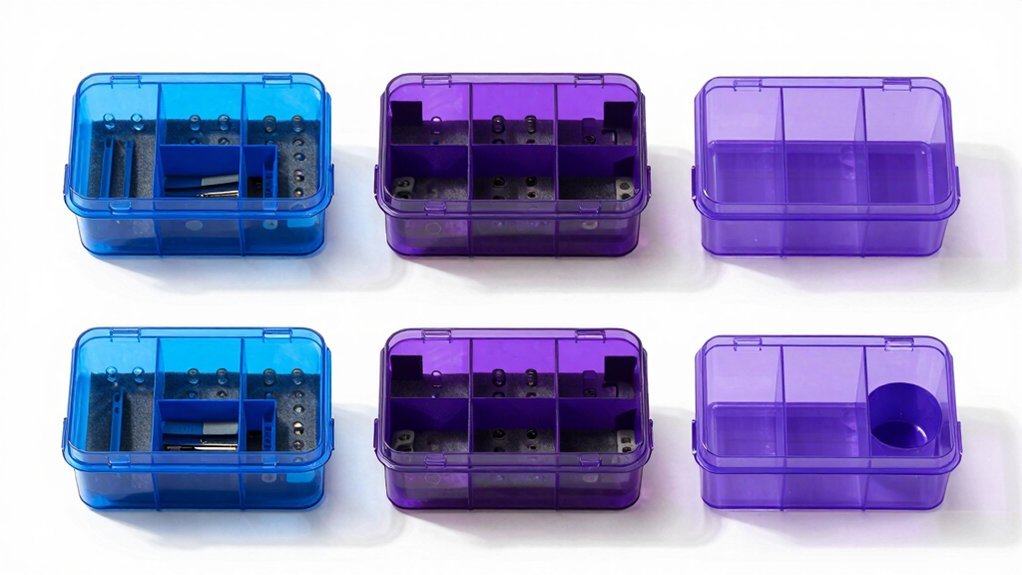

For transport, you'll want to use conductive fluted plastic or high-impact polypropylene containers that offer superior strength and reusability. These materials, combined with pink anti-static convoluted foam inserts, create a secure environment for your electronics during shipping. Corstat materials provide an economical option for short-term shipments.

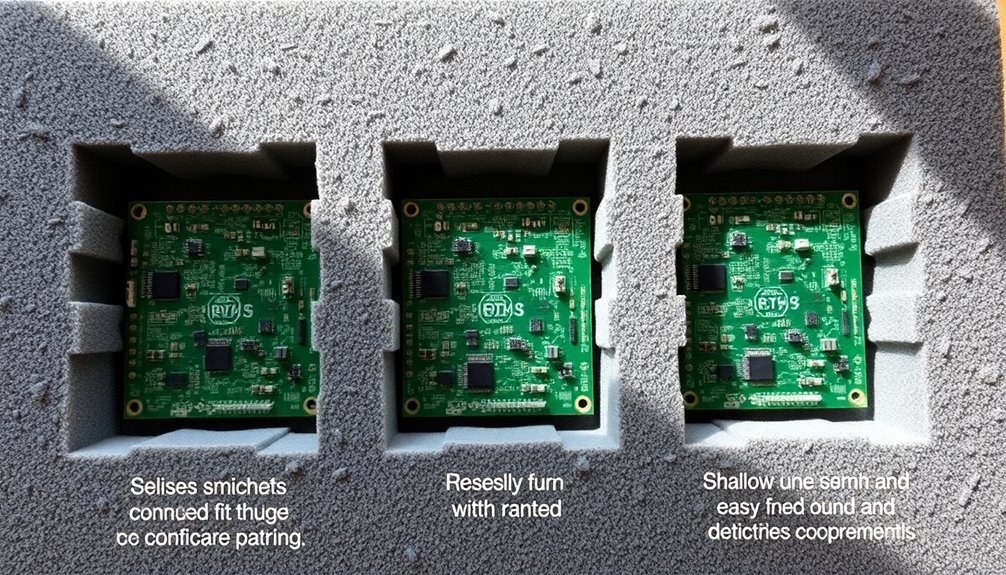

When storing PCBs, use strong shelving units that won't sag under the weight of your inventory. Choose compartmentalized trays or containers with custom foam dividers to prevent boards from making contact with each other. You'll need ESD-safe materials throughout your storage system to maintain consistent protection against static discharge.

Picture rows of black conductive "pizza box" style containers, each with pink egg-crate foam securing valuable circuit boards.

Imagine sturdy industrial shelving lined with ESD-safe containers, perfectly compartmentalized with foam dividers.

Visualize custom-cut foam inserts cradling each PCB in its own protective pocket.

For both transport and storage, guarantee your packaging guards against dust, moisture, and physical impact while incorporating proper vibrational damping materials. Stack containers evenly and observe maximum height limits to prevent toppling.

Testing Foam Package Effectiveness

To properly test your foam packaging for circuit boards, you'll need to conduct systematic drop impact analyses that simulate real shipping conditions and potential mishandling.

Use high-quality conductive black foam to ensure maximum static protection during impact tests.

You should run environmental stress tests to verify the foam's protective qualities under varying temperature, humidity, and pressure conditions.

Before shipping your circuit boards, it's crucial to verify the foam package quality through standardized testing procedures, including measuring conductivity with a multimeter and checking for proper component insertion in high-density conductive foams.

Drop Impact Analysis Methods

Drop-impact analysis serves as a crucial testing methodology for evaluating foam packaging effectiveness in protecting circuit boards. You'll need to use specialized software like ABAQUS/Explicit to simulate the dynamic interactions between your circuit board and foam packaging during impact.

A proper material model using crushable foam plasticity ensures accurate prediction of foam deformation behavior during impact scenarios. By applying initial velocities and defining material properties, you can accurately predict how your packaging will perform under real-world drop conditions.

When conducting drop impact analysis, you'll want to focus on three key areas: mesh refinement, contact modeling, and experimental validation. Use shell elements for circuit boards and solid elements for foam components to achieve precise simulation accuracy while maintaining reasonable computation times.

Picture a high-speed camera capturing the precise moment of impact, with foam compression waves rippling through the material.

Visualize color-coded stress distributions across your circuit board, highlighting potential failure points.

Imagine acceleration graphs showing the dramatic difference between protected and unprotected boards during impact.

You can validate your simulation results using Digital Image Correlation and accelerometer measurements. This dual approach confirms your foam packaging design meets protection requirements by comparing computational predictions with actual drop test data.

Environmental Stress Test Protocols

Environmental stress testing requires a thorough approach to validate foam packaging's protective capabilities for circuit boards. You'll need to conduct high-temperature testing for at least 160 hours at temperatures up to 125 degrees Celsius using burn-in ovens to evaluate thermal integrity and material degradation. Testing must include thorough continuity and resistance measurements to ensure package integrity.

During this process, it's essential to use appropriate materials like FR4, ceramic, or polyamide boards based on your temperature requirements.

You should perform mechanical stress testing through vibration and humidity assessments while evaluating your foam cushioning's effectiveness. The foam inserts must demonstrate reliable shock absorption properties and withstand various environmental conditions.

For ESD protection, you'll want to implement both component-level and system-level testing using appropriate antistatic or conductive foam materials.

To complete your testing protocol, you'll need to conduct drop tests that simulate real-world scenarios. Pay close attention to how your foam packaging performs under combined environmental factors like temperature, humidity, and vibration.

Remember to assess the foam material's properties throughout these tests and verify that your packaging design maintains component integrity under all stress conditions.

Pre-Shipment Quality Verification

Building upon your environmental stress testing protocols, the next step involves conducting thorough pre-shipment quality verification. You'll need to wait until production reaches at least 80% completion before initiating inspections that cover functionality, performance, durability, and dimensional accuracy of your foam packaging solutions.

Your verification process should incorporate both ASTM D4168 testing methods. Method A utilizes free-fall drop tests to simulate real-world conditions, while Method B employs shock test machines for precise measurements. You'll want to pay special attention to shock-absorbing characteristics through dynamic cushioning tests and cushion drop testing.

Picture your foam packaging undergoing repeated impact tests, with specialized platens dropping from specific heights to evaluate shock absorption.

Visualize the careful inspection of vent holes and mold prevention units, confirming they're properly positioned for maximum protection.

Imagine the meticulous verification of shipping markings, export carton dimensions, and weight measurements.

This thorough verification process not only guarantees compliance and quality but also safeguards your brand reputation and reduces costs associated with damaged circuit boards. You'll receive necessary certificates for import and billing purposes, providing peace of mind that your circuit boards will arrive safely.

Environmental Impact Considerations

The dual nature of foam packaging presents both environmental benefits and challenges when protecting circuit boards. While it helps minimize overall packaging size and enables space-efficient shipping, you'll need to evaluate both the advantages and drawbacks of using foam materials in your packaging solution.

On the positive side, foam packaging can substantially reduce your carbon footprint through efficient shipping and lower material usage. You'll use less energy in manufacturing compared to alternative materials, and the packaging can often be reused multiple times before requiring disposal. These benefits directly contribute to reduced greenhouse gas emissions and help mitigate climate change impacts.

However, you should be aware of the environmental risks and recycling challenges. Foam materials aren't typically accepted in kerbside recycling, requiring specialist facilities for proper disposal.

If you're implementing foam packaging, you'll want to research manufacturers that offer their own recycling programs. Remember that improper disposal can lead to long-term environmental issues – foam is non-biodegradable, can persist for hundreds of years, and may break down into harmful microplastics.

Consider establishing a take-back program or partnering with specialized recyclers to guarantee responsible end-of-life management.

Foam Selection Criteria

Selecting appropriate foam packaging requires careful consideration of multiple critical factors that directly impact circuit board protection. You'll need to evaluate your circuit board's sensitivity to static, shock, and environmental conditions to choose the most suitable foam type.

For static-sensitive components, anti-static foam is essential to prevent electrostatic discharge damage, while high-impact electronics might require durable expanded polyethylene foam.

Consider these visual examples of proper foam selection:

- A delicate microcontroller nestled in soft, pink anti-static foam with precisely cut cavities

- Heavy power supply modules secured in dense, blue PE foam with reinforced corner protection

- Surface-mount components housed in lightweight, black conductive foam with custom-sized compartments

Your foam selection should also account for expected shipping conditions and handling requirements. You'll want to verify the foam's physical properties through standardized tests like tear strength (ASTM D3574-17) and compression resistance.

Don't forget to check the supplier's customization capabilities, as you'll likely need precisely cut foam to match your circuit board's dimensions and component layout. The foam's hardness and density should provide adequate cushioning without putting excessive pressure on sensitive components.

Frequently Asked Questions

How Long Can PCBS Safely Remain Stored in Foam Packaging?

You can store gold-plated PCBs for up to 6-12 months in foam packaging, while those with surface treatments like silver, tin, or OSP last 3 months. You'll need proper temperature and humidity controls.

Can Foam Packaging Be Reused After Exposure to Extreme Temperatures?

You shouldn't reuse foam packaging after extreme temperature exposure as it may have lost its protective properties. First inspect for visible damage, warping, or degradation. If you notice any changes, it's best to replace it.

What Cleaning Solutions Are Safe to Use on ESD Foam?

You'll want to use Detergent 8 Low-Foaming Ion-Free Detergent or similar solutions without chelating agents and metal cations. Use warm 1-3% solutions and rinse thoroughly. Don't use cleaners containing sodium compounds.

How Often Should Foam Packaging Materials Be Inspected for Degradation?

You should inspect your foam packaging materials monthly for signs of wear and degradation. Don't wait longer than 3 months between checks, as foam can deteriorate quickly under adverse environmental conditions.

At What Humidity Levels Does Foam Packaging Begin to Lose Effectiveness?

You'll notice foam packaging starts losing its effectiveness when humidity exceeds 80%. At levels of 86%, 93%, and 98%, you'll see rapid moisture absorption that can compromise the foam's structural integrity and protective capabilities.

In Summary

You'll find that proper foam packaging protection for circuit boards requires careful material selection and attention to ESD safety protocols. Choose appropriate anti-static or conductive foams, guarantee proper fit with custom inserts, and regularly test your packaging solutions. Don't forget to think about environmental factors and sustainability when selecting foam materials. With these practices, you can confidently protect your sensitive electronic components during storage and transit.

Leave a Reply