Tracking your ESD environment's daily numbers helps you prevent costly equipment damage and maintain strict compliance standards. You'll catch potential issues early through continuous monitoring of humidity, static charges, and grounding effectiveness, saving up to 1,000% ROI annually on preventive maintenance. Smart sensors and automated systems minimize human error while providing real-time insights into your facility's ESD protection levels. Regular data collection supports informed decision-making, streamlines quality control, and guarantees employee safety through proper training validation. Understanding these numbers puts you in control of your facility's ESD protection and operational success.

Cost Savings Through Daily Monitoring

Anyone managing an ESD environment knows that daily monitoring isn't just about compliance—it's a powerful cost-saving strategy.

When you implement continuous monitoring systems, you'll catch potential issues before they become expensive problems, greatly reducing repair costs and downtime. You'll also eliminate the need for time-consuming periodic testing and manual logs, freeing up your staff for more critical tasks.

Your energy costs will decrease through optimized cooling and power usage, while preventive maintenance becomes more efficient as you spot and address issues early. Smart sensors placed at multiple rack positions help ensure comprehensive environmental monitoring across your facility.

You'll extend the life of your equipment, reducing the frequency and costs of replacements. The automated nature of continuous monitoring also minimizes human error in testing and documentation, saving you from costly mistakes.

Preventing Equipment Breakdown

You'll find that early warning detection systems are essential for identifying potential ESD issues before they cause equipment failure.

Regular monitoring of your ESD environment numbers lets you spot trends and address problems while they're still minor, preventing costly breakdowns and repairs.

Maintaining proper temperature and humidity control through consistent monitoring helps create a stable environment that minimizes the risk of electrostatic discharge incidents.

Early Warning Detection Systems

Early warning detection systems stand out as a critical line of defense against equipment breakdown, combining both embedded ESD technology and predictive monitoring capabilities.

Manufacturers can leverage advanced testing methodologies to consistently verify their detection systems' effectiveness. You'll find these systems particularly effective at detecting and recording ESD events while validating protection measures at both chip and system levels. By implementing telemetry monitoring, you can track event severity and frequency in your deployed products, giving you real-time insights into potential issues.

Critical slowing down (CSD) serves as your indicator of approaching system failures, while early warning signals (EWSs) help you anticipate tipping points before they occur. You'll want to train your operators to recognize these signals and maintain detailed documentation of all maintenance activities and equipment failures.

- Your equipment's survival depends on catching problems before they become catastrophic

- You're protecting millions in assets with every early detection

- You'll sleep better knowing your systems are constantly monitored

- You're preventing costly production delays and downtime

- Your team becomes more proactive instead of reactive

Through consistent monitoring and documentation, you'll create a robust early warning system that helps prevent unexpected breakdowns and extends equipment life.

Remember to regularly test your embedded detection technology and maintain thorough maintenance logs for insurance purposes.

Cost-Effective Equipment Maintenance

Building upon effective early warning systems, implementing cost-effective equipment maintenance strategies can greatly reduce ESD-related failures and extend the life of your valuable equipment.

Regular monitoring of ESD risks through standard operating procedures helps maintain consistent protection levels.

By investing in proper ESD control measures, you'll see impressive returns – up to 1,000% ROI annually and potential savings of $95 for every dollar spent on prevention.

You'll need to focus on three key areas to maintain your equipment effectively.

First, verify proper grounding and bonding of all workstations and equipment, while using ESD-safe materials throughout your facility.

Second, optimize your workspace with ESD-resistant flooring, conductive wheels on carts, and humidity control through HVAC systems.

Third, train your employees thoroughly on proper handling techniques and PPE usage.

You can cut repair and replacement costs by over 50% by implementing these measures consistently.

Use anti-static brushes, wipes, and conductive vacuum cleaners for regular maintenance, and maintain strict workspace organization policies.

Don't forget to regularly inspect and test grounding connections while monitoring compliance with ESD prevention practices.

These steps will greatly reduce warranty claims and improve your equipment's overall reliability.

Real-Time Compliance Verification

Real-time monitoring of your ESD control systems lets you catch and address compliance issues before they escalate into equipment failures.

You'll receive immediate alerts when any parameters fall outside acceptable standards, allowing for quick corrective actions to maintain ANSI/ESD S20.20 compliance.

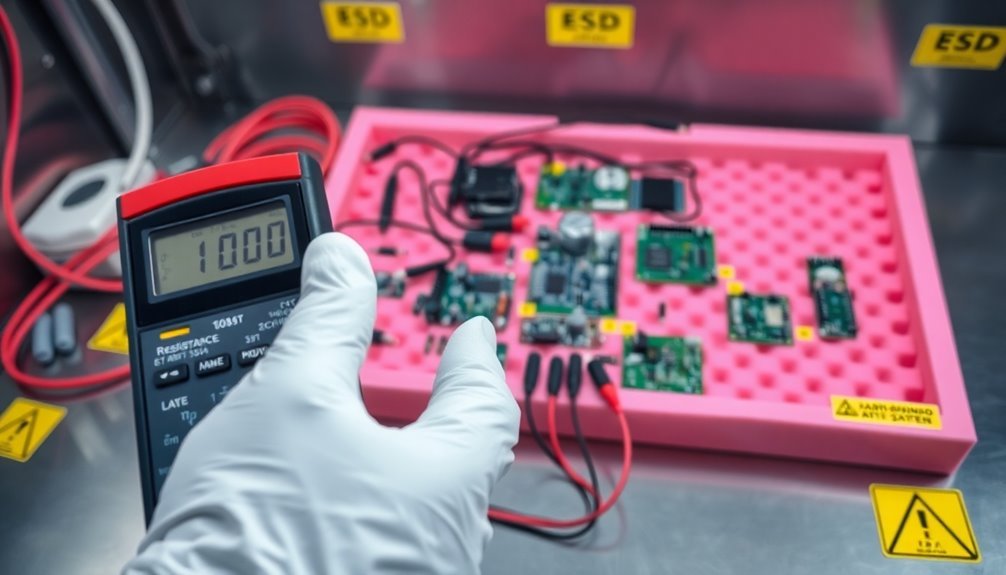

ESD safety equipment worn by workers provides critical protection during manufacturing and testing processes.

Your automated verification systems continuously track performance metrics and compliance data, ensuring your facility meets required standards around the clock.

Monitor Alerts Prevent Issues

Automated alerts serve as vigilant guardians in ESD compliance monitoring, providing instant notifications when environmental conditions deviate from acceptable ranges. You'll receive immediate warnings when temperature, humidity, or other critical parameters fall outside their specified limits, enabling you to take swift corrective action.

This real-time monitoring system continuously collects high-frequency data, giving you a thorough view of your ESD environment that manual methods simply can't match. The automated data collection eliminates potential human errors in the monitoring process.

With automated alerts, you'll stay ahead of potential compliance issues before they escalate into costly problems. The system's early warning capabilities help you maintain consistent environmental conditions and prevent audit failures.

You're empowered to make data-driven decisions quickly, as the continuous data stream provides detailed insights into process changes and their impacts.

- Protect your valuable electronic components from invisible ESD damage

- Save thousands in potential product losses and rework costs

- Maintain your facility's reputation for quality and reliability

- Prevent sleepless nights worrying about failed audits

- Confirm your team's hard work isn't compromised by environmental factors

The system's immediate notification feature transforms reactive problem-solving into proactive prevention, greatly reducing your risk of compliance violations and production losses.

Standards Met In Realtime

While automated alerts provide immediate notifications, continuous compliance verification takes your ESD protection to the next level. Through integrated sensors and IoT platforms, you'll maintain real-time monitoring of your ESD environment, guaranteeing you're meeting ANSI/ESD S20.20 standards consistently rather than relying on periodic manual checks. The sensor cost reduction has made implementing these monitoring systems more accessible than ever.

You'll benefit from standardized ESDA guidelines that streamline your verification process across four key reliability categories. The Calibre PERC platform offers pre-coded checks that eliminate manual coding errors and simplify your ESD verification workflow.

Regular audits of your ESD control products become more efficient when supported by real-time data analytics. Your verification process becomes more robust as IoT platforms automatically track compliance, while real-time monitoring identifies potential ESD risks before they impact your operations.

You're able to analyze and debug verification results quickly using the Calibre RVE results viewer. This thorough approach guarantees you're not just meeting standards but maintaining consistent ESD protection across your entire operation.

The combination of automated compliance checks and predictive analytics helps you maintain effective ESD control while reducing the time and effort required for verification.

Data-Driven Quality Control

Modern manufacturing relies on data-driven quality control to transform traditional inspection methods into systematic, analytical processes. By implementing automated data collection and analysis, you'll reduce your reliance on manual inspections while gaining real-time insights into your ESD environment's performance.

Your quality control processes integrate seamlessly with main factory operations, allowing continuous monitoring throughout the product lifecycle. Quality assurance costs are significantly reduced by addressing issues proactively.

Through data-driven quality control, you're able to compare samples against established models instantly, detect deviations early, and make informed decisions based on thorough data analysis. This approach connects quality control with predictive maintenance, creating a holistic management system that incorporates customer feedback into your quality models.

- Your products' quality could make or break someone's critical medical device

- Every undetected ESD issue risks thousands in damaged components

- Real-time monitoring helps you prevent costly recalls and reputation damage

- Your customers trust you to maintain consistent ESD protection

- Each data point represents a potential improvement in workplace safety

While implementing data-driven quality control presents challenges, especially in brownfield sites with legacy systems, the benefits far outweigh the obstacles.

You'll need a robust industrial cloud infrastructure and effective integration of multiple data sources, but the resulting improvements in quality control efficiency make the investment worthwhile.

Employee Safety and Awareness

Building on your data-driven quality control system, employee safety and awareness form the foundation of an effective ESD protection program. You'll need to guarantee your team understands the risks and consistently follows ESD control measures outlined in standards like ANSI/ESD S20.20. Regular training sessions and monitoring help your employees internalize proper ESD-safe practices.

| Impact Level | Safety Risk | Required Action |

|---|---|---|

| Critical | Direct contact with sensitive components | Wear complete ESD-safe gear and verify grounding |

| High | Movement through ESD-sensitive areas | Use proper footwear and maintain grounding connection |

| Medium | Handling ESD-safe packaging | Follow prescribed handling procedures |

| Low | Working in adjacent areas | Maintain awareness of ESD zones |

Your employees become your first line of defense against ESD damage when they're properly trained and equipped. Make certain they understand how to use ESD-safe materials, maintain proper grounding, and report any incidents immediately. Regular ESD surveys and equipment calibration checks should become part of their daily routine. By maintaining appropriate humidity levels and air quality in your facility, you'll help your team work more effectively while reducing static generation risks.

Building Better Production Standards

Production standards for ESD control must align with internationally recognized benchmarks like ANSI/ESD S20.20 and IEC 61340-5-1.

You'll need to implement standardized processes that guarantee consistent performance across your manufacturing environment. By following these established guidelines, you're creating a framework that protects sensitive electronic components while maintaining efficient production flows.

When you standardize your ESD control practices, you're not just meeting requirements – you're building a foundation for reliable manufacturing outcomes.

Your production standards should incorporate proper grounding techniques, environmental controls, and specific material requirements that meet or exceed industry specifications.

- Your facility's reputation and customer trust depend on maintaining rigorous ESD standards

- Every ESD-related production failure costs you money and delays your delivery timelines

- Your team's confidence grows when they work within clear, well-documented standards

- You'll see immediate improvements in product quality and reduced failure rates

- Your competitive edge sharpens as you demonstrate consistent ESD control excellence

Risk Management Fundamentals

You'll find that tracking ESD environment data provides essential insights for proactive risk management, enabling you to spot potential issues before they escalate into costly problems.

By monitoring key metrics like humidity levels, static charges, and grounding system effectiveness, you're establishing a data-driven foundation for your risk mitigation strategy.

Your focus on prevention through systematic data collection will prove more cost-effective than reacting to ESD incidents after they occur.

Mitigation Through Data Tracking

Data-driven ESD management forms the cornerstone of effective risk mitigation in modern manufacturing environments. By implementing continuous monitoring systems, you'll gain access to thorough static field histories that reveal potential hazards before they cause damage.

Your ability to track and analyze E-field data enables real-time decision-making and immediate corrective actions when values exceed acceptable limits.

Through static charge heat maps and integrated datalog collection, you can precisely identify problem areas and correlate line station data with fixture measurements. This systematic approach helps you optimize ionizer placement and enhance your ESD control measures beyond traditional audit capabilities.

- Your production line's safety hangs in the balance with every undetected static charge

- Each data point you collect could prevent thousands in potential damage

- Real-time alerts empower you to protect sensitive components instantly

- Your team's awareness grows stronger with every measurement tracked

- You're building a fortress of protection around your valuable products

Prevention Over Reaction

Every successful ESD management program hinges on prevention rather than reaction. By identifying and analyzing potential risks in your ESD environment before they escalate into problems, you'll save time, resources, and protect your sensitive components more effectively. Your focus should be on developing thorough prevention strategies that address risks before they materialize.

You'll need to implement a systematic approach that includes regular monitoring of ESD parameters and swift responses to any deviations. This means tracking your environmental conditions daily and establishing clear thresholds for action. When you integrate risk management principles into your operational planning, you're better positioned to make evidence-driven decisions that protect your facility.

Remember that prevention isn't a one-time effort – it requires continuous improvement and adaptation. You should regularly assess your prevention strategies' effectiveness and adjust them based on real-world data.

Performance Metrics That Matter

Successful ESD environment tracking hinges on selecting the right performance metrics. You'll need to focus on measurements that directly impact your ESD control program's effectiveness while avoiding the trap of collecting data just for data's sake.

By choosing a limited set of well-defined metrics, you'll get clearer insights into your program's performance and potential issues. Your metrics should combine both leading and lagging indicators. While lagging metrics like ESD event counts tell you what's already happened, leading metrics such as static level trends help you prevent future problems.

Use tools like the SCS EM Eye for precise event detection and establish clear operational baselines to quickly identify deviations from normal conditions.

- Your facility's static levels could be silently damaging sensitive components right now

- Each undetected ESD event risks thousands in equipment damage

- Your current metrics might be missing critical early warning signs

- Tomorrow's audit could reveal compliance gaps you didn't know existed

- Your team's daily actions directly impact your ESD protection effectiveness

Remember to focus on practicality and clear causal links when selecting metrics. Choose measurements that your team can consistently track and that provide actionable insights for improving your ESD control program.

Environmental Control Success

Organizations that master environmental control in their ESD programs share common characteristics: consistent monitoring, thorough training, and unwavering commitment to improvement.

You'll find these successful operations maintain strict daily tracking of their ESD control measures while ensuring every employee understands their role in maintaining a static-safe environment.

To achieve environmental control success, you need to focus on reducing electrostatic charge generation at its source. This means equipping your facility with dissipative materials, implementing proper grounding systems, and using appropriate packaging for ESDS items.

You'll want to establish clear metrics for monitoring these controls and train your staff to recognize and report any deviations from established standards.

Your success depends on maintaining continuous improvement practices. Set measurable goals, conduct regular audits, and provide ongoing training to keep pace with evolving technologies.

Don't forget to regularly assess your environment's compliance with ESD standards and make adjustments as needed. When you track your daily numbers effectively, you'll spot trends, identify potential issues before they become problems, and maintain a consistently protected environment for your sensitive components.

Strategic Decision Making Tools

Decision-making excellence in ESD control relies on robust monitoring tools and data-driven strategies. When you implement continuous monitoring systems, you'll gain immediate insights into ESD failures and can take swift corrective actions. You won't just save money on testing costs – you'll also protect your valuable equipment from damage while enhancing product quality and reliability.

By tracking your ESD environment numbers daily, you're establishing a proactive approach that transforms ESD control from a simple requirement into a competitive advantage. You'll reduce equipment failures, minimize product rejections, and maintain consistent compliance with industry standards. The real-time data allows you to make informed decisions quickly, improving your operational efficiency and productivity.

- Your equipment investments are protected 24/7, giving you peace of mind

- Your customers receive consistently high-quality products they can trust

- Your team spends less time on manual testing and more on value-added tasks

- Your compliance status stays current, eliminating audit-time stress

- Your bottom line improves through reduced failures and testing costs

With continuous ESD monitoring, you're not just collecting data – you're building a foundation for strategic excellence that drives sustainable business success.

Continuous Improvement Practices

Building on your robust monitoring system, continuous improvement practices take ESD control to the next level. You'll need to regularly evaluate and audit your ESD program, using the collected data to identify areas that require enhancement.

By integrating these improvements into your existing quality system, you're creating a more effective static-safe environment. Your continuous improvement strategy should include periodic testing of ESD protective equipment and materials to verify their performance.

You'll want to establish clear SOPs and update them as new risks emerge or technology changes. Don't forget to implement appropriate control measures based on your specific work environment and identified risks.

Make employee training a cornerstone of your improvement efforts. You should conduct regular sessions tailored to your staff's education level and verify their understanding through practical assessments.

Maintain your ESD protective devices through routine cleaning and testing, using static locators and grounding test equipment to spot potential issues. Involve employees from different areas in the auditing process to boost participation and compliance.

Remember to maintain strong reporting and feedback mechanisms to keep management, your ESD team, and employees informed about program effectiveness.

Maintaining Certification Requirements

For ongoing ESD facility certification, you'll need to meet rigorous requirements established by accredited third-party bodies. Your facility must undergo annual recertification audits that typically last up to two days, focusing on your ESD program's documentation, control elements, training, and calibration processes.

As of July 2023, all facility certifications must comply with ANSI/ESD S20.20-2021, while IEC 61340-5-1 certifications can use either the 2016 or 2024 version until May 2025.

To maintain your certification status and protect your investment, you'll need to stay current with these critical requirements:

- Your ESD Protected Areas must consistently meet stringent control standards to safeguard sensitive components

- Your staff needs continuous training and validation of their ESD control practices

- Your documentation must demonstrate ongoing compliance with all certification requirements

- Your measurement equipment requires regular calibration and verification

- Your control program must align with ISO 9001:2015 quality management framework

Remember that only accredited certification bodies can perform valid audits. Some organizations, like German Cert Co., Ltd. and Novostar, have lost their accreditation, so verify you're working with currently approved certifiers to maintain your facility's compliance status.

Frequently Asked Questions

How Long Does It Take to Train New Staff on ESD Monitoring?

You'll need 60 minutes to 2 hours for basic ESD monitoring training, but if you're pursuing advanced or specialized roles, your training could extend from 2 hours to several days over 4 weeks.

Can ESD Monitoring Systems Integrate With Existing Manufacturing Software Platforms?

Yes, you'll find modern ESD monitoring systems easily integrate with your existing manufacturing software through Ethernet connections, providing real-time data streaming and automated reporting while seamlessly connecting with factory monitoring platforms.

What Backup Procedures Exist if Continuous Monitoring Systems Fail?

You'll need to implement full daily backups, hourly incremental backups, and maintain offsite storage. If monitoring fails, you can rely on these redundant systems while initiating immediate repair procedures.

How Often Should ESD Monitoring Equipment Be Recalibrated?

You'll need to recalibrate your ESD monitoring equipment daily for wrist straps, semi-annually for continuous monitors, and quarterly for worksurfaces. Make sure to conduct a full annual audit of all ESD stations.

Which Industries Have the Strictest ESD Environment Tracking Requirements?

You'll find the electronics industry has the strictest ESD requirements, followed by healthcare, telecommunications, and automotive sectors. These industries demand rigorous monitoring due to sensitive components and safety concerns.

In Summary

By tracking your ESD environment's daily numbers, you're taking control of both immediate and long-term success. You'll reduce costs, prevent equipment failures, and guarantee compliance while keeping your team safe. Don't underestimate the power of consistent monitoring – it provides valuable data for strategic decisions and continuous improvement. Make daily tracking a priority to maintain certification and optimize your ESD protection program.

Leave a Reply