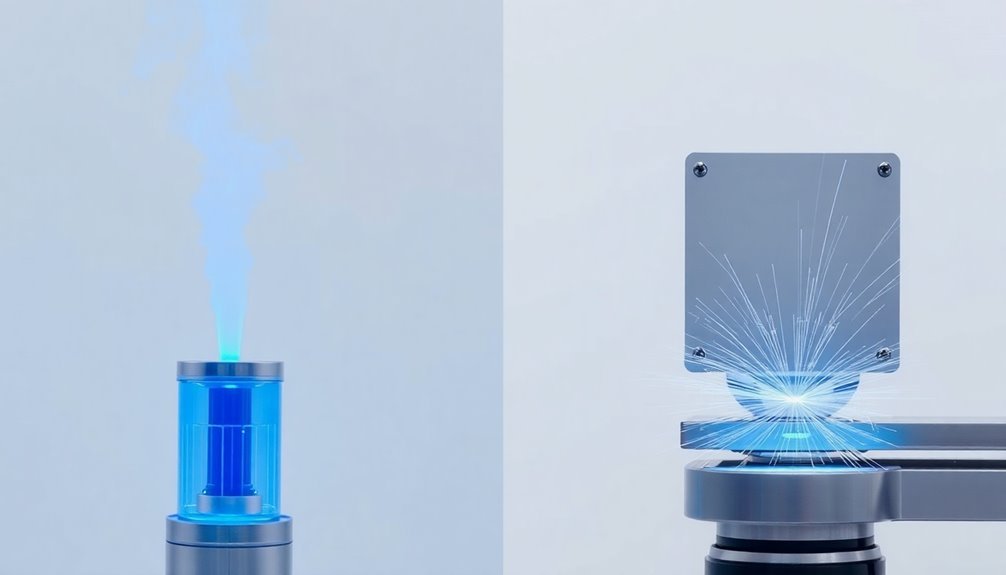

Air ionizers and static eliminators serve distinct purposes in managing static electricity. You'll find that ionizers treat entire spaces by releasing ions into the air, while static eliminators target specific surfaces directly. Ionizers typically use fan-driven systems and work continuously, whereas eliminators often employ compressed air for precise applications. You'll need more maintenance for ionizers due to their filters, but they offer broader coverage. Static eliminators cost less initially but may require more frequent replacement. While both technologies control static, they differ in operating range, energy consumption, and industrial applications. Understanding these key differences will help you choose the most effective solution for your needs.

Primary Function and Purpose

Both air ionizers and static eliminators tackle static electricity head-on, but they serve distinct primary functions.

Air ionizers focus primarily on creating a static-free environment by releasing positive and negative ions into the air. You'll find them most effective in controlled spaces like electronics manufacturing facilities and clean rooms, where they protect sensitive components and prevent static-related damage. These devices typically operate with low ozone emissions to maintain safety standards.

Static eliminators, however, take a more direct approach to neutralizing static charges on specific surfaces and materials. They're designed to work at remote distances and often incorporate high-pressure air purges to remove both static and dust simultaneously. Static eliminators achieve impressive results by neutralizing charges in 0.5 seconds for optimal efficiency.

You'll notice they're particularly effective for fast-moving products and surfaces with extremely high charge levels.

When it comes to purpose, air ionizers excel at maintaining static-free workstations and preventing operators from introducing static charge into controlled environments.

Static eliminators, on the other hand, target larger areas and specific applications like coating and printing processes where static could cause fires or explosions.

They're your go-to solution for industrial settings where you need to neutralize static on non-conducting materials during production processes.

Design Features and Construction

Looking into the design features of these devices reveals distinct engineering approaches. Air ionizers typically employ fan-driven or compressed air systems to circulate ionized air throughout larger spaces. Modern designs can achieve static elimination over 3000mm range for large-scale applications.

You'll find they're built with adaptable mounting options, allowing end-to-end placement without air gaps, and they often feature adjustable airflow settings. Their construction includes stainless steel models for harsh environments and patented connectors with built-in ground protection. The systems are designed to maintain effectiveness at distances up to 1-foot when cleaning surfaces.

Static eliminators, however, showcase more specialized engineering features. They utilize de Laval nozzles for supersonic air delivery and incorporate an I.R.G. structure with internal ground plates for rapid static elimination.

You'll notice their construction emphasizes compact design, with ultra-small elimination heads for precision work. They're built with electrode probes that leverage fluid mechanics to enhance air volume and feature a louver structure with high-power fans for wide coverage.

What sets static eliminators apart is their advanced technology integration, including the Coanda effect for wide-angle elimination and straight air boosters for ultra-high speeds.

They also incorporate pulse AC methods, generating balanced positive and negative ions, while self-diagnostic functions monitor ion generation and maintenance needs.

Ion Generation Methods

The internal mechanisms of air ionizers and static eliminators center on their distinct ion generation methods. While both devices create ions to neutralize static charges, they employ different approaches to achieve this goal.

Air ionizers primarily use electrical ionization through AC or DC power systems, creating both positive and negative ions that are released into the surrounding air. You'll find that these devices often incorporate fans to enhance ion distribution, though they may produce ozone as a byproduct. DC systems operate effectively at greater distances compared to AC alternatives.

Static eliminators, on the other hand, focus specifically on neutralizing static charges through electrical static elimination systems. You can find them in various forms, including static bars and point ionizers, often combined with compressed air or blowers for more precise application. Active static eliminators offer the advantage of non-contact operation for sensitive materials.

Their effectiveness depends heavily on factors like distance and target speed. For specialized applications, you'll encounter non-electrical ionization methods using alpha particles from Polonium-210, particularly in intrinsically safe environments. These alpha ionizers work effectively within a 1-3 inch range without airflow and are ideal for extreme temperature conditions.

Both systems require some moisture in the air to function efficiently and support ISO 20.20 ESD compliance in workplace settings.

Operating Range and Efficiency

When choosing between air ionizers and static eliminators, operating range and efficiency serve as essential differentiating factors. You'll find that compressed air static eliminators can effectively operate up to 6 meters, while advanced models like the SJ-H Series can cover areas up to 3m. The ion balance becomes significant, with high-performance units maintaining a precise +/- 1V for sensitive applications. The integration of De Laval nozzles enhances overall efficiency while minimizing air consumption requirements. Regular monitoring of ion output levels is crucial for maintaining optimal static neutralization performance.

| Feature | Air Ionizers | Static Eliminators |

|---|---|---|

| Coverage Range | Limited to localized areas | Up to 6m with compressed air |

| Speed | Moderate elimination rate | As fast as 0.5 seconds |

| Ion Balance | Variable performance | Maintains +/- 1V precision |

Your choice should take into account environmental conditions, as both humidity and temperature impact performance. While compressed air systems offer excellent efficiency, they're not always ideal for every industrial setting. You'll need to reflect that static can rebuild if friction continues, so permanent solutions may require continuous ionization. For high-speed applications, you'll want to opt for stronger AC or DC bars, especially when dealing with fast-moving targets or high static charges. The pulse AC method delivers superior ion generation, producing more ions with better control capabilities.

Maintenance and Upkeep Requirements

Maintaining ideal performance of both air ionizers and static eliminators requires specific cleaning protocols and regular inspection schedules.

You'll need to regularly vacuum or wipe filters with a damp cloth, using deionized water for general cleaning and isopropyl alcohol for stubborn buildup. It's essential to prevent standing water on collection blades and other components.

For corona ionizers, you must pay special attention to the emitter points. Clean them with alcohol-moistened swabs and check for particle accumulation or erosion. If your unit has automatic cleaning features, such as fan-type ionizers with built-in brushes, you'll still need to verify they're working effectively.

You should inspect components monthly for damage, including frayed wires and loose connections. Use industry-standard tests like CPM or PVS to assess performance and adjust your maintenance schedule accordingly.

When verifying functionality, measure offset voltage and discharge times after cleaning the unit thoroughly. If your device has adjustable settings, you'll need to zero the offset voltage and retest.

Always follow the manufacturer's recommended service procedures and use appropriate testing equipment like Charge Plate Monitors or Ionization Test Kits.

Safety Standards and Regulations

Safety standards governing air ionizers and static eliminators fall under strict regulatory frameworks, with UL 867 serving as the primary safety standard for electrostatic air cleaners and ion generators. If you're considering these devices, you'll need to confirm they display the UL mark, indicating compliance with essential safety requirements, including ozone emission testing under Section 40.

In California, you'll find even stricter regulations through the California Air Resources Board (CARB). Since 2010, all air cleaners must be tested and certified before they can be sold in the state, with mandatory certification labels on packaging implemented in 2011.

The 2020 amendment eliminated exemptions for electronic in-duct air cleaners, requiring ozone emissions testing by October 1, 2022.

You should be aware that health and safety organizations, including the EPA, don't recommend electronic air cleaners due to ozone emission concerns. Instead, they suggest using HEPA filters for particulate removal.

When selecting either an air ionizer or static eliminator, you'll need to verify compliance with these safety standards and consider that international safety standards increasingly emphasize the importance of protecting both people and the environment through harmonized regulations.

Cost and Long-Term Value

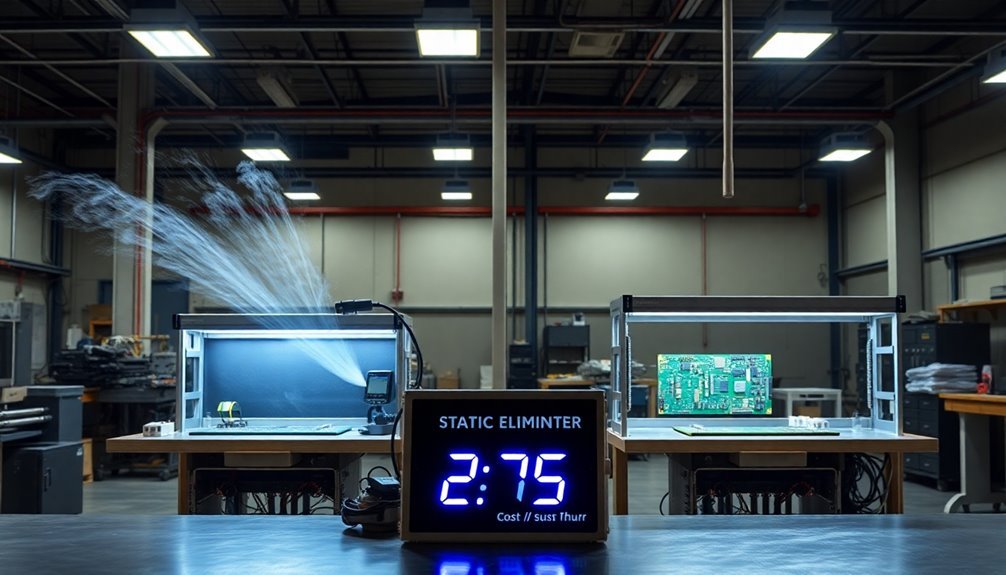

With respect to budget evaluations, the initial investment for active static eliminators ranges from $350 to over $2,065, while passive solutions come at a lower upfront cost.

However, you'll need to factor in the long-term value and operating expenses when making your decision.

While active eliminators require power to operate, they provide superior efficiency and reliability in static removal. You won't need frequent replacements, and many models come with extensive warranties, such as EXAIR's 5-year coverage.

Compressed air systems offer a balanced approach, providing energy efficiency with intermittent use and lower maintenance requirements.

Here are the key financial factors to take into account:

- Operating costs – Active systems consume power but deliver consistent performance, while passive solutions require no power but need frequent replacement.

- Maintenance expenses – Active eliminators need minimal upkeep since they don't require surface contact, unlike passive solutions that wear down over time.

- Production efficiency – Active systems reduce static-induced quality issues, leading to fewer rejected products.

- Cleaning costs – Ionized air systems decrease the effort needed for surface cleaning, resulting in labor savings.

Industrial Vs Consumer Applications

You'll notice stark differences between industrial and consumer static control equipment, with manufacturing environments requiring specialized high-performance units designed for continuous operation and precise static elimination.

While industrial models often integrate directly into production lines and feature advanced monitoring systems, consumer units are typically standalone devices meant for home or small office use.

Manufacturing equipment comes with higher power outputs, faster neutralization times, and stricter safety standards compared to the simpler, lower-powered consumer versions designed for general air purification and basic static control.

Manufacturing Vs Home Use

Throughout the manufacturing sector, industrial-grade ionizers and static eliminators serve distinctly different purposes than their consumer counterparts. While home units primarily focus on air purification and basic static reduction, manufacturing applications require precise control, high-speed operation, and compliance with stringent safety standards.

You'll find industrial static elimination systems equipped with compressed air capabilities that can neutralize charges from up to 6 meters away, while home units typically operate within a limited range.

Manufacturing environments demand specialized features that aren't necessary for residential use:

- High-performance industrial ionizers maintain ultra-precise ion balance for sensitive electronics manufacturing, whereas home units focus on general air quality improvement.

- Manufacturing units often integrate with compressed air systems and offer wide-range airflow adjustment for specific application needs.

- Industrial static eliminators must meet strict NFPA standards to prevent fires and explosions in coating and printing operations.

- Factory units require regular maintenance checks and cleaning protocols to guarantee consistent performance in demanding environments.

When you're choosing between manufacturing and home units, consider that industrial models offer customization options, high-speed operation, and specialized safety features that aren't typically found in consumer-grade products.

Specialized Industry Equipment

Specialized industrial equipment takes static elimination to an entirely new level compared to consumer-grade ionizers. You'll find chassis mount ionizers integrated into automation lines and bar-type eliminators protecting entire warehouse entrances, whereas home units typically only cover small areas.

| Industrial Equipment | Consumer Applications |

|---|---|

| Chassis mount systems for automation lines | Portable desktop units |

| Overhead ionizers covering multiple workstations | Single-room coverage |

| High-precision pulse AC/DC with +/- 1V balance | Basic ion generation |

| Bar-type eliminators for warehouse entrances | Small form factor designs |

| Photoionization systems for critical processes | Simple corona discharge |

When you're working in manufacturing, you'll need industrial-grade static eliminators that comply with NFPA standards and maintain precise ion balance for sensitive electronics. These systems often incorporate air-assisted ionization and advanced corona discharge methods that you won't find in consumer models. You'll also notice that industrial units require regular maintenance and calibration to maintain their strict performance standards, while offering features like adjustable ion ratios and integration with facility-wide ESD protection systems.

Environmental Impact and Considerations

Understanding the environmental impact of air ionizers and static eliminators requires careful consideration of several key factors.

You'll need to evaluate how these devices affect air quality, energy consumption, and overall environmental adaptability in your specific setting.

When comparing these technologies, consider these critical environmental aspects:

- Air Quality Management: Air ionizers actively release ions that neutralize particles and improve air quality, while static eliminators focus primarily on charge neutralization without considerable air quality impact.

- Energy Efficiency: You'll find that non-blower ionizers typically consume less energy than compressed air systems, though both types require ongoing power consumption for operation.

- Humidity Interactions: Both technologies work effectively across varying humidity levels, but ionizers can complement existing humidity control systems for better overall performance.

- Installation Requirements: Proper placement and maintenance considerably impact environmental effectiveness, with ionizers generally requiring more strategic positioning to maximize air treatment coverage.

Your choice between these technologies should factor in your specific environmental constraints, including material sensitivity, airflow requirements, and energy consumption limitations.

Remember that while both systems serve distinct purposes, their environmental impact varies based on installation, maintenance, and operational parameters.

Performance in Specialized Settings

Building on environmental factors, the performance of air ionizers and static eliminators varies markedly across different specialized settings.

You'll find that air ionizers with airflow excel in environments with hard-to-reach surfaces and large areas requiring static elimination. When you're dealing with compressed air systems, they'll effectively deliver ions over greater distances while maintaining efficiency.

However, you'll need to evaluate airless solutions for delicate applications. If you're working with lightweight materials or small components, blowerless ionizers are your best choice to prevent displacement. You can achieve better results by using GND plates embedded within static eliminators, as they'll improve ion delivery without requiring airflow.

The efficiency of your static elimination system will depend on environmental conditions. You'll notice slower neutralization in low humidity environments, while active eliminators will handle faster-moving targets more effectively than passive systems.

When you're working in intrinsically safe environments, alpha ionizers can provide reliable performance, though their range is limited without airflow. For manual operations, you'll find handheld anti-static air guns offer precise control while maintaining energy efficiency, supporting your ESD compliance efforts without introducing harmful substances.

Frequently Asked Questions

Can Static Eliminators and Air Ionizers Be Used Simultaneously in the Same Space?

Yes, you can use static eliminators and air ionizers together in the same space. They're compatible and can actually enhance each other's performance for better static control and dust removal in your facility.

How Do Temperature and Humidity Affect the Performance of These Devices?

You'll notice that high temperatures and humidity can reduce your devices' effectiveness by disrupting ion generation and mobility. For best results, maintain moderate temperature levels and lower humidity in your workspace.

What Is the Typical Lifespan of Emitter Points in Both Devices?

You'll find emitter points typically last 1-2 years with proper maintenance, but your actual results depend on usage, environment, and cleaning frequency. Regular inspections help you determine when they need replacement.

Do These Devices Interfere With Wireless Communications or Electronic Equipment?

You'll find these devices typically don't interfere with wireless communications or electronics, as they're designed to minimize EMI. Just keep them properly grounded and maintain safe distances from sensitive equipment for best results.

Can These Devices Be Safely Used Around Food Processing Operations?

You can safely use static eliminators and ionizers in food processing if they're CARB-compliant, properly maintained, and strategically placed. Always verify they meet FDA standards and don't exceed ozone emission limits.

In Summary

You'll find that both air ionizers and static eliminators serve distinct purposes in your environment. While air ionizers focus on purifying air quality and removing contaminants, static eliminators specifically target electrostatic discharge problems. Consider your specific needs, budget, and application requirements when choosing between them. Remember, they're not interchangeable solutions – each excels in its intended purpose and operating environment.

Leave a Reply