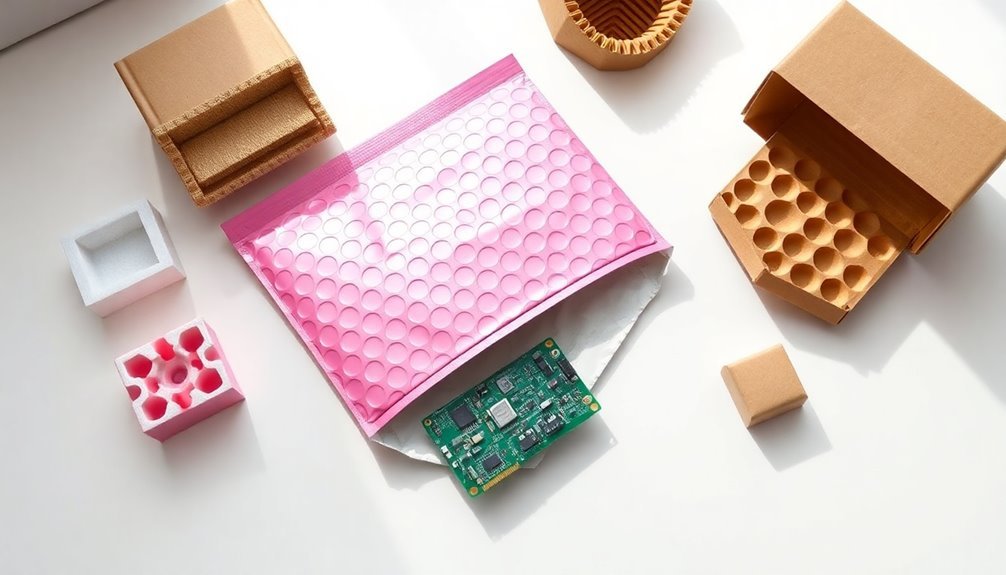

When shipping electronics, you'll want to choose from these five proven protective packaging options. Start with anti-static or static shielding bags to guard against electrical damage. Next, consider eco-friendly paper solutions like corrugated cardboard with custom inserts for shock absorption. Add custom edge protection systems using foam or plastic guards to prevent corner damage. Include vapor barrier technology with desiccants to control moisture levels. Finally, opt for non-abrasive foam alternatives like wool or mushroom-based packaging for cushioning. Each option offers unique benefits, and combining them strategically will maximize your shipment's protection.

Anti-Static Shipping Bags

Anyone working with electronics knows the critical importance of anti-static shipping bags in protecting sensitive components during transit. These specialized bags come in several types to suit your specific needs: pink anti-static bags made from polyethylene terephthalate, static-dissipative bags for non-essential applications, and reclosable bags with convenient zippers for heavy-duty use.

The bags are typically made from 100% virgin LDPE for optimal protection against static charges. You'll find anti-static bags offer significant benefits beyond static protection. They're humidity-resistant, cost-effective, and durable enough to withstand repeated use.

However, it's vital to understand their limitations. Unlike static shielding bags, they won't protect against electrostatic discharge (ESD), making them unsuitable for highly sensitive components.

When you're shipping electronics, choose your packaging based on the level of protection needed. Anti-static bags work well for non-essential applications and components that may encounter static-sensitive environments. For critical electronics requiring ESD protection, you'll need to invest in static shielding bags instead.

Remember that while anti-static bags might cost less, they don't provide the multi-layered protection of their static shielding counterparts. Always verify that your chosen packaging complies with industry standards like MIL-PRF-81075 for electrical goods shipping.

Eco-Friendly Paper Packaging Solutions

Today's growing environmental concerns have sparked a revolution in electronics packaging, with eco-friendly paper solutions leading the charge. You'll find innovative options like PaperFoam's biodegradable packaging made from industrial starch and natural fibers, offering both protection and environmental responsibility.

For your electronics shipping needs, you can choose from Ranpak's PadPak and FillPak systems, which provide exceptional shock absorption while maintaining sustainability. These paper-based solutions effectively replace traditional bubble wrap and plastic void fills. The high-resolution graphics on paperboard packaging enhance brand visibility during shipping and storage.

You'll also benefit from Billerud's corrugated transport boxes, which combine tough liners with their advanced Flute technology for superior strength.

When you're looking to optimize your shipping efficiency, consider Ranpak's automated right-sizing solutions that minimize void space and reduce freight costs.

For individual product protection, Greenwrap and flexi-hex air sleeves create protective hexagonal structures that rival traditional cushioning materials.

Mondi Group's Protective Mailer, made from 100% paper, offers another reliable option for shipping smaller electronic items.

These solutions don't just protect your products – they're fully recyclable through regular paper recycling systems, helping you meet sustainability goals while maintaining product safety.

Custom Edge Protection Systems

Custom edge protection systems serve as the first line of defense for electronics during shipping. When you're packaging electronic items, you'll find various options including corrugated corner boards, foam protectors, and plastic edge guards, each designed to distribute weight and prevent damage during transit.

To choose the right protection system, you'll need to measure your items carefully and consider the shipping conditions they'll face. The materials are available in various sizes and lengths to accommodate different packaging needs. If you're shipping delicate electronics, foam corner protectors offer superior cushioning, while plastic edge protectors provide better weather resistance.

For standard shipments, corrugated cardboard corners can effectively distribute weight and protect edges.

You'll find that implementing custom edge protection can substantially reduce your shipping losses and boost customer satisfaction. When you're selecting materials, consider using recyclable options like corrugated cardboard with fluting or recycled paper-based protectors to minimize environmental impact.

Don't forget to complement your edge protection with stretch film for additional security. By investing in proper edge protection, you'll save money by preventing damage to expensive electronics and safeguard your products to arrive safely at their destination.

Vapor Barrier Technology

While protecting electronics during shipping requires multiple safeguards, vapor barrier technology stands as a vital defense against moisture damage. You'll find MIL-PRF-131 as the government's preferred barrier material, often combined with activated clay desiccants to control humidity levels.

When you're shipping electronics internationally, especially via ocean freight, proper vapor barrier packaging becomes essential to prevent condensation and potential equipment failure. Corrugated materials provide the first line of defense in the overall packaging strategy.

For effective moisture protection, you'll want to take into account these key elements:

- Heat-sealing and vacuum sealing to minimize trapped air volume

- Humidity indicator cards or plugs to monitor moisture levels

- Anti-static wraps combined with vapor barriers for thorough protection

You can enhance your vapor barrier strategy by implementing smart barriers that adjust to temperature and humidity changes.

When you're packaging bare metal surfaces or sensitive electronic components, it's essential to use vapor-proof materials that meet industry standards. Don't forget to include desiccants conforming to MIL-D-3464 specifications within your vapor barrier bags.

This combination creates a robust defense system that'll protect your electronics from moisture-related damage during transit, regardless of environmental conditions or shipping duration.

Non-Abrasive Foam Alternatives

Modern electronics shipping demands more than traditional bubble wrap, which is why non-abrasive foam solutions have become essential for protecting sensitive components. When you're selecting protective materials, you'll find that polyethylene (PE) and polyurethane (PU) foams offer excellent shock absorption while remaining gentle on delicate surfaces.

| Foam Type | Key Benefits | Best Applications |

|---|---|---|

| PE Foam | Cost-effective, moisture-resistant | Large electronics, custom-cut needs |

| PU Foam | Superior cushioning, moldable | Fragile components, precise fits |

| Conductive | EMI protection, permanent conductivity | Static-sensitive parts |

| Anti-Static | Static dissipation, various colors | Circuit boards, displays |

You'll want to take into account specialized options like conductive and anti-static foams for components that are particularly vulnerable to static discharge. The surface resistance of 10^4 to 10^9 ohms helps effectively dissipate electrostatic charges that could damage sensitive electronics. These materials come in distinct colors – black for conductive and pink for anti-static – making identification easy during packaging.

For environmentally conscious shipping, you can opt for alternative materials like wool packaging or eco-friendly composites. These sustainable options provide comparable protection while reducing environmental impact. When combined with corrugated cardboard or custom-designed solutions, they create thorough protection systems for your electronic shipments.

Frequently Asked Questions

How Long Can Electronics Safely Remain in Anti-Static Packaging Before Degradation Occurs?

You shouldn't store electronics in anti-static packaging for more than one year, as the material's protective properties will degrade. After this time, the packaging can actually start generating static charges itself.

What Temperature Ranges Can Protective Packaging Materials Withstand During Transit?

You'll find most protective packaging materials can safely handle temperatures from -20°C to 70°C (-4°F to 158°F), but you should check specific ratings for materials like EPS foam, VIP panels, and bubble wrap.

Are There Specific Packaging Requirements for Shipping Electronics Containing Lithium Batteries?

You'll need rigid outer packaging, anti-static inner materials, and proper battery labels. Make certain you've secured batteries to prevent shorts, included UN identification numbers, and followed weight limits under 66lbs for compliant shipping.

How Do Different Altitudes Affect the Protective Capabilities of Electronic Packaging?

You'll notice that high altitudes cause packaging expansion due to pressure differences. This can weaken protective materials, reduce insulation effectiveness, and compromise your electronics' safety if you haven't used altitude-specific packaging solutions.

Can Protective Packaging Materials Interfere With RFID Tracking Systems During Shipping?

Yes, your packaging materials can interfere with RFID tracking. Metal and aluminum components block signals completely, while glass reduces read range. You'll need specialized on-metal RFID tags or spacers to maintain tracking effectiveness.

In Summary

Protecting your sensitive electronic shipments doesn't have to be complicated or environmentally harmful. You'll find an ideal solution among these five packaging alternatives, whether you're shipping delicate circuit boards or complete systems. From anti-static bags to eco-friendly paper solutions, you've got options that'll keep your electronics safe while reducing waste. Choose the right protective packaging, and you'll guarantee your items arrive damage-free.

Leave a Reply