When comparing protective foams vs bubble wrap, you'll find three standout foam options that offer superior protection: EPS foam (13.5-28 kg/m³ density), PE foam, and anti-static foam. While bubble wrap provides affordable, quick-wrap protection for lighter items, these foams deliver better cushioning for heavy or valuable products. EPS foam is 98% air and highly customizable, PE foam offers higher density for heavier items, and anti-static foam excels at protecting electronics. You'll pay more upfront for foam, but it provides better long-term value through superior protection, reduced storage needs, and lower replacement costs. Understanding the key differences will help you make the most cost-effective choice for your specific needs.

Anti-Static Properties and Performance

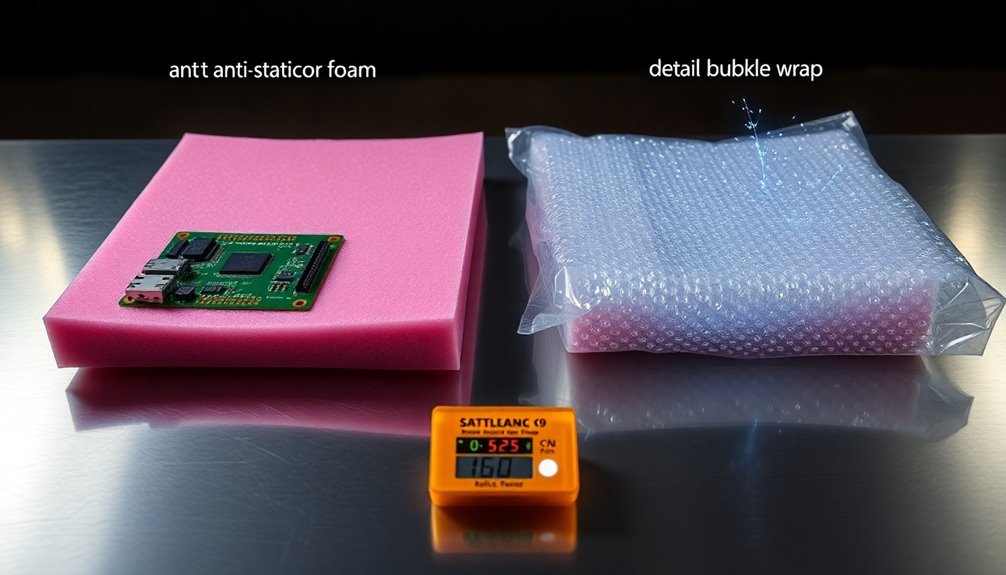

While regular packaging materials may suffice for everyday items, anti-static bubble wrap offers specialized protection for electronics and sensitive equipment. This material is uniquely formulated with additives that prevent static electricity buildup, making it essential for packaging electronic components like computer chips, circuit boards, and hard drives. The material's specially formulated polyethylene composition ensures consistent static protection throughout its entire surface.

When you're handling sensitive electronics, you'll want to note that anti-static bubble wrap provides dual protection. It combines excellent cushioning and shock absorption with ESD prevention capabilities.

You can identify it by its distinctive pink color, setting it apart from standard bubble wrap. However, you should understand its limitations – it won't shield against external static charges but rather prevents static buildup within the packaging itself.

For thorough protection, you might consider combining anti-static bubble wrap with other materials like foam. This combination leverages the non-abrasive properties of foam while maintaining static-prevention benefits.

If you're dealing with items that are particularly sensitive to ESD, you'll need to supplement with static shielding materials for complete protection, as the bubble wrap's performance can deteriorate with repeated use.

Material Construction and Density

Through careful examination of material construction and density, protective foams offer distinct advantages over bubble wrap in respect of structural stability.

EPS foam, comprising 98% air and 2% solid material, comes in various densities ranging from 13.5 to 28 kg/m³, allowing you to choose the right protection level for your needs. Choosing Standard Light grade EPS foam at 13.5 kg/m³ is perfect for lightweight packaging applications.

PE foam provides higher density and less compressibility than bubble wrap, making it ideal for protecting heavier items.

When you need maximum durability, polyurethane foam offers densities from 1.2 to 5.6 lbs per cubic foot, while latex foam maintains a consistent 5.6 lbs per cubic foot with excellent resilience.

While bubble wrap's air-filled structure makes it lightweight and suitable for basic protection, it can't match the customizable density options of protective foams.

You'll notice that EPS, PE, and polyurethane foams can be tailored to specific applications, from delicate electronics to heavy machinery.

The solid construction of these foams provides superior strength and stability, especially in situations where bubble wrap's air pockets might collapse under pressure or repeated impact.

Price Points and Cost Analysis

When you're comparing protective packaging options, bubble wrap offers a lower initial investment with small rolls starting at $5, while foam solutions typically require a higher upfront cost due to customization needs.

You'll find significant savings through bulk purchases for both materials, with bubble wrap rolls of 100 x 24 feet available for around $25 and foam becoming more cost-competitive in larger quantities.

Popular retailers like Home Depot and U-Haul make both packaging materials readily accessible for convenient in-store pickup or delivery.

Your long-term value will depend on your specific needs, as bubble wrap provides adequate protection at a lower price point for general items, while foam's higher cost is justified for valuable or fragile products requiring superior protection.

Initial Investment Comparison

A savvy business owner must carefully evaluate the initial investment costs between protective foam and bubble wrap solutions. While traditional bubble wrap rolls appear more cost-effective upfront, you'll need to weigh the long-term financial implications of your choice.

Bubble on demand systems require a higher initial investment due to specialized machinery, but they'll typically pay for themselves through reduced storage, transport, and labor costs. One pallet of bubble on demand film provides the equivalent protection of ninety regular rolls. You'll find that specialized anti-static films for these systems cost more but provide essential protection for electronic items.

If you're evaluating foam packaging, expect higher upfront costs, especially for custom solutions. However, foam's superior protection capabilities make it cost-effective for high-value items like electronics and furniture.

You'll find that standard bubble wrap is more affordable when purchased in bulk, making it ideal for lighter items and general shipping needs.

When evaluating your investment, think about the fact that Styrofoam offers a middle-ground solution, providing custom-molding capabilities at a relatively lower cost. Your choice should align with your specific shipping needs, product weights, and protection requirements while thinking about how the initial investment will impact your long-term operational expenses.

Bulk Purchase Savings

Smart bulk purchasing strategies can dramatically reduce your packaging expenses, especially when evaluating bubble wrap solutions. When you buy bubble wrap in bulk, you'll typically see significant cost reductions per unit, which can substantially improve your bottom line.

Wholesale platforms like Alibaba offer competitive bulk pricing, and you'll find that minimum order quantities often start at ten rolls. The reduced overhead costs from bulk orders contribute directly to improved profitability.

To maximize your bulk purchase savings, you'll need to assess several key factors. First, guarantee you've accurately forecasted your demand to avoid overstocking or running short.

You'll also want to compare prices from multiple suppliers to secure the best deals while maintaining quality standards. Don't forget to take into account your available storage space – bulk purchases require adequate storage facilities to prevent damage and maintain efficiency.

You'll find that bulk purchasing not only reduces your per-unit costs but also streamlines your shipping operations. With a reliable stock of bubble wrap on hand, you can handle peak demand periods more effectively and maintain continuous operations without costly restocking delays.

This preparedness gives you a competitive advantage while potentially reducing packaging waste through more efficient ordering practices.

Long-Term Value Assessment

Conducting a thorough cost analysis reveals significant differences between protective foam and bubble wrap solutions. While foam packaging typically demands a higher initial investment, it's crucial to evaluate the long-term value when protecting your valuable items.

You'll find that bubble wrap offers more affordable options, with small Enviro-bubble rolls starting at $5 and bulk rolls reaching $30 for larger quantities. Custom foam inserts offer shock absorption properties that can reduce long-term replacement costs for high-value items.

When evaluating long-term value, take into account these key factors:

- Protection Level – Foam provides superior protection for heavy and fragile items, potentially reducing damage-related costs despite higher upfront pricing.

- Volume Requirements – Bulk purchases of bubble wrap can substantially reduce per-unit costs, with options like 250' x 12' rolls offering better value at $30.

- Sustainability Impact – Corrugated bubble alternatives, made from 95% post-consumer waste, deliver both environmental benefits and potential cost savings.

- Item Specificity – Your choice should align with product weight and fragility; lightweight items often don't justify foam's premium cost.

For businesses handling delicate merchandise, foam's superior protection may justify the higher investment. However, if you're shipping moderate-weight items, bubble wrap's cost-effectiveness and bulk pricing options make it a practical choice.

Environmental Impact and Sustainability

The environmental impact of packaging materials has become a critical concern, with bubble wrap contributing substantially to the 400 million tons of plastic waste generated annually. Single-use packaging like bubble wrap is discarded almost immediately after using it. When you choose bubble wrap, you're selecting a material that can take up to 1,000 years to decompose, leaching harmful chemicals into soil and waterways during this process.

You'll find that protective foams offer a more environmentally conscious alternative. They're lighter, require less storage space, and can reduce shipping emissions.

While bubble wrap clogs landfills and creates barriers to natural decomposition, foam packaging provides superior thermal insulation and non-abrasive protection for your sensitive items.

The rise of eCommerce has intensified the need for sustainable packaging solutions. You can now choose from eco-friendly alternatives like Hexcel Wrap, made from recycled paper, or flat-packed cushioning materials that minimize storage requirements.

With only 9% of plastic waste being recycled globally, your choice of packaging material makes a significant impact. By selecting foam-based solutions or combining them strategically with minimal bubble wrap use, you're helping reduce the 11 million tonnes of plastic waste that pollute our oceans each year.

Handling Electronic Components Safely

When you're comparing foam and bubble wrap for electronic components, you'll find that both offer distinct anti-static properties, with specialized foam providing consistent static dissipation and anti-static bubble wrap offering a cost-effective barrier against electrical charges.

Impact resistance tests show that foam's dense structure provides superior protection against drops and compression, while bubble wrap excels at absorbing vibration and sudden shocks. The polyethylene layers in bubble wrap create an additional safeguard against moisture damage.

Your choice between the two materials should consider both the static sensitivity of your components and the type of physical impacts they're likely to encounter during shipping or handling.

Static Control Properties Compared

Safe handling of electronic components requires proper static control measures, and understanding the differences between protective foams and bubble wrap is essential. While both materials offer protection, their static control properties vary substantially.

Conductive foam provides full Faraday cage shielding and prevents static buildup, making it ideal for long-term storage of sensitive electronics. Anti-static foam, recognizable by its pink color, works well for single-trip shipping but requires additional static shielding bags for complete protection.

When choosing between protective materials, consider these key differences:

- Static dissipative foam offers a balanced approach, allowing gradual discharge of static electricity while preventing sudden shocks that could damage components.

- Conductive foam's reusable nature makes it cost-effective for long-term applications, though you'll need to check its quality regularly.

- Anti-static foam's performance depends on humidity levels, while conductive foam maintains consistent properties.

- Anti-static bubble wrap can be used, but foam generally provides better static control and thermal protection.

For maximum protection, you can combine foam and bubble wrap, taking advantage of foam's superior static control properties while benefiting from bubble wrap's cushioning capabilities.

Impact Resistance Testing Results

Building upon static control considerations, impact resistance plays a major role in protecting electronic components during shipping and handling. Testing methods like ASTM D7136 and ISO 6603 have shown that foam materials excel at absorbing and distributing impact energy through their cellular structure.

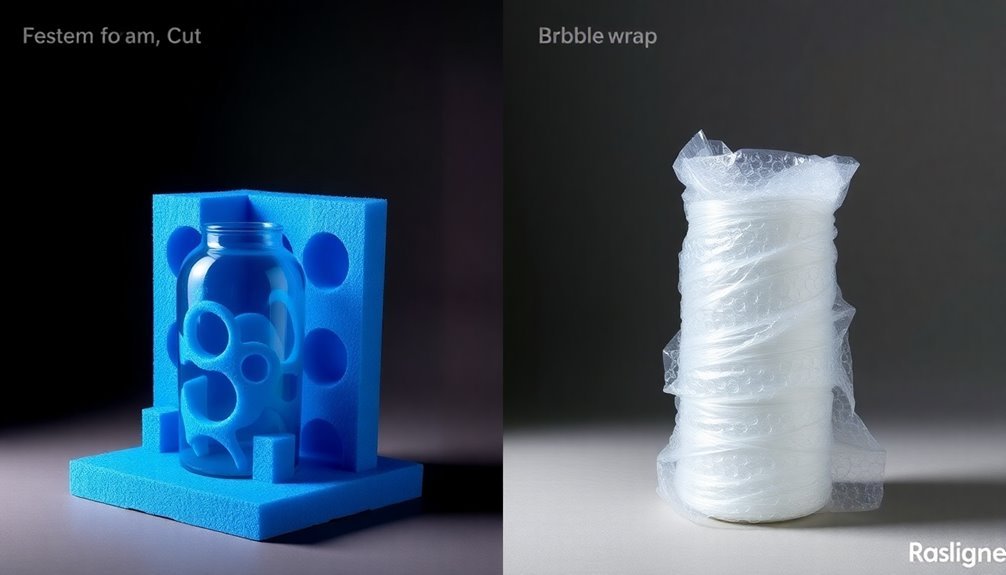

You'll find that foam packaging offers superior protection for your electronic components compared to bubble wrap. While both materials provide cushioning, foam's non-abrasive nature and customizable density make it particularly effective for protecting sensitive electronics.

You can have foam fabricated to precisely fit your components, ensuring omni-directional protection against impacts.

When you're choosing protective packaging, consider that foam materials are generally thinner and lighter than bubble wrap while maintaining excellent shock absorption. You'll get better results using polyethylene foam or EPE foam, as they're specifically designed for durability and strong cushioning properties.

If you need maximum protection, you can combine foam with bubble wrap, though foam alone is typically sufficient for most electronic applications.

For reliable test results, ASTM D4168 evaluates shock-absorbing characteristics, confirming that foam-in-place packaging consistently outperforms alternatives in protecting electronics during transit and handling.

Shock Absorption Testing Results

Recent testing reveals significant differences in shock absorption between protective foams and bubble wrap. PE foam's higher density and unique cellular structure provide superior protection against impacts and vibrations.

You'll find that foam's tiny air cells distribute force more evenly across the surface, while bubble wrap's larger air pockets can collapse under sustained pressure.

When it comes to shock absorption performance, testing has identified these key differences:

- PE foam maintains its protective properties longer due to its higher durability and resistance to tearing, making it ideal for extended shipping periods.

- The material's reduced compressibility offers better protection against continuous vibration, especially vital for sensitive electronics.

- Foam's consistent density provides more reliable impact protection across its entire surface, unlike bubble wrap's variable air pocket distribution.

- Temperature fluctuations have minimal effect on foam's shock-absorbing capabilities, whereas bubble wrap can lose effectiveness in extreme conditions.

While both materials offer adequate protection for general shipping needs, you'll want to choose PE foam when dealing with delicate surfaces, electronics, or items requiring precise shock absorption control.

The material's non-abrasive properties and static-resistant nature make it particularly suitable for protecting polished surfaces and sensitive electronic components.

Custom Packaging Solutions

Custom packaging has evolved beyond simple protection to become a strategic business solution. If you're looking to enhance your product protection while maintaining brand identity, several companies offer thorough solutions tailored to your needs.

Arka and Packlane provide online design studios where you can create and visualize your packaging in real-time, while companies like 105 Packaging focus on eco-friendly options.

When choosing between foam and bubble wrap for your custom packaging, consider your product's specific requirements. Foam offers superior protection for heavy or fragile items but comes at a higher cost.

Bubble wrap provides a more cost-effective solution for lighter items while maintaining adequate protection. Both materials can be integrated into custom packaging designs through providers like Refine Packaging, which offers expert support during the design process.

You'll find that most custom packaging companies now offer instant quotes, design support, and varying minimum order quantities. If you're integrating with an e-commerce platform, look for providers like Arka that connect directly with Shopify and BigCommerce.

Remember to factor in production times, which can range from 10 days with Packlane to 20-25 business days with other providers.

Frequently Asked Questions

Can Bubble Wrap or Foam Be Reused Multiple Times for Shipping?

Yes, you can reuse both bubble wrap and foam multiple times for shipping. They'll remain effective if you handle them carefully, store them properly, and verify they're not damaged or excessively worn between uses.

Which Option Provides Better Protection Against Extreme Temperatures During Transit?

Foam provides superior protection against extreme temperatures during transit. You'll find it offers thermal insulation and temperature regulation, while bubble wrap doesn't protect against temperature fluctuations at all. Choose foam for temperature-sensitive items.

How Long Do Foam and Bubble Wrap Maintain Their Protective Properties?

Your foam's protective properties will diminish over time due to molecular saturation, while your bubble wrap stays effective as long as bubbles aren't popped. Store both in dry, dark places for maximum longevity.

Does Humidity Affect the Performance of Foam Versus Bubble Wrap?

Yes, humidity substantially affects your foam's performance through moisture absorption and degradation, while your bubble wrap maintains consistent protection regardless of humidity levels. You'll find bubble wrap more reliable in humid conditions.

Which Option Is Better for Shipping Items With Irregular Shapes?

For shipping irregular shapes, you'll want to use foam as it's more customizable and provides better protection. While it's pricier, foam's ability to be custom-cut guarantees a secure fit for oddly-shaped items.

In Summary

You'll find that protective foam outperforms bubble wrap in most categories, especially for electronics and fragile items. While bubble wrap remains cheaper, foam's superior shock absorption, anti-static properties, and customization options make it worth the investment. Consider your specific needs – if you're shipping sensitive equipment or need reusable protection, polyethylene or polyurethane foams are your best choice. They're also more environmentally responsible than traditional bubble wrap.

Leave a Reply