To prevent static buildup while cleaning your data center, you'll need HEPA-filtered vacuums with ESD-safe attachments that capture particles as small as 0.3 microns. Use antistatic microfiber cloths and specialized non-conductive cleaning solutions like Staticide cleaners for surface cleaning. Keep static dissipative mops and dusters handy for routine maintenance, and install proper entrance mats to reduce dirt accumulation. Don't forget essential grounding equipment like wrist straps and ESD mats for safe hardware handling. Maintain humidity levels between 40-60%, and implement regular cleaning schedules with proper personnel training. These fundamentals are just the beginning of a thorough static prevention strategy.

Essential Antistatic Cleaning Equipment

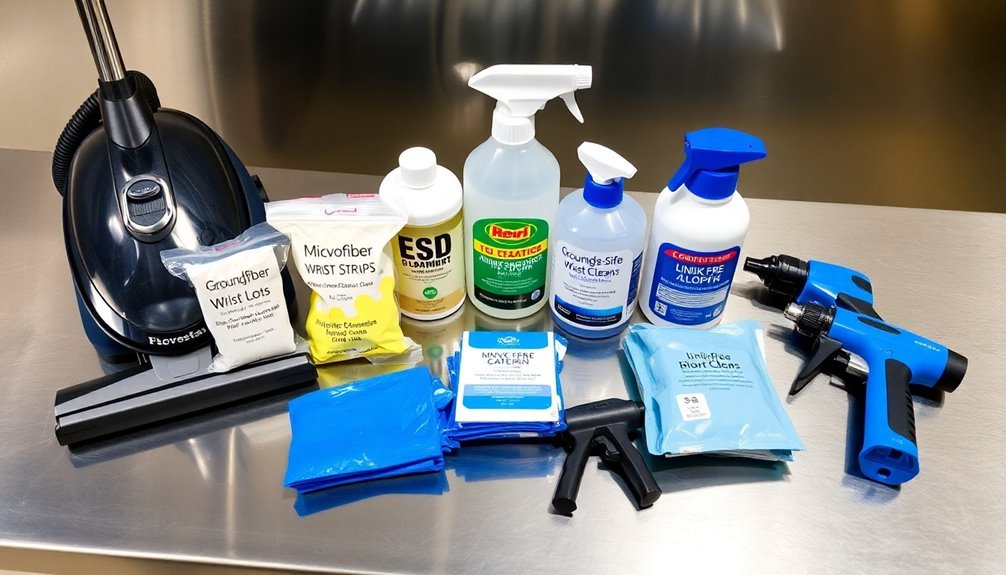

Data center cleaning protocols require thorough antistatic equipment to protect sensitive electronic components from electrostatic discharge (ESD) damage. You'll need to invest in HEPA-filtered vacuums that are specifically designed to be ESD-safe, as they effectively capture microscopic particles that could otherwise harm your equipment.

Your essential toolkit should include antistatic cloths and specialized cleaning agents that won't leave static charges or residue on surfaces. Don't forget to use antistatic sprays, which are formulated to neutralize static buildup on various surfaces throughout your facility.

You must also implement proper grounding equipment, including wrist straps and antistatic mats, to safely discharge any static electricity during cleaning operations. Certified cleaning personnel should be trained to handle all specialized equipment to prevent damage during maintenance.

When selecting cleaning agents, choose non-abrasive, non-static, and non-conductive options to guarantee maximum protection for your sensitive equipment. You'll want to verify that all your cleaning supplies meet industry standards for ESD safety.

Remember to store your antistatic cleaning equipment properly and replace items as needed to maintain their effectiveness. Regular inspection of your cleaning tools will help guarantee they continue to provide adequate protection against static buildup.

Data Center Static Prevention Tools

You'll need to equip your data center with essential static-safe cleaning supplies, including specialized anti-static wipes, sprays, and vacuums that won't generate harmful electrostatic discharge.

Your floor mat protection systems should include ESD-rated mats and tiles strategically placed throughout the facility, particularly in high-traffic areas and workstations. Proper grounding of these materials helps prevent static discharges below 10V that can damage sensitive electronic components.

Managing anti-static devices, such as wrist straps and grounding equipment, requires regular testing and maintenance to confirm they're functioning correctly and providing consistent protection against static electricity.

Static-Safe Cleaning Equipment

Maintaining a static-free environment requires specialized cleaning equipment designed specifically for data center applications. You'll need to equip your cleaning team with ESD-safe cleaning kits that include anti-static wipes, sprays, and specialized tools that won't generate harmful static charges during maintenance activities.

Start with anti-static cleaning liquids and sprays that decay static charges on contact. These solutions are specially formulated for use around sensitive electronic equipment and won't leave residues that could compromise hardware performance. HEPA vacuum cleaners are essential for removing dust without dispersing particles into the air.

You'll want to pair these with static control mops and dusters that prevent charge buildup during routine cleaning tasks.

Don't forget to implement ESD-safe trash cans throughout your facility to properly dispose of materials without creating static risks.

Your cleaning personnel should also use anti-static wristbands and mats while performing their duties to maintain proper grounding.

Make sure they're trained in proper static control procedures and regularly inspect all cleaning equipment for wear or damage.

When selecting cleaning supplies, verify they comply with industry standards and are part of a thorough static control program that includes regular risk assessments and equipment maintenance schedules.

Floor Mat Protection Systems

Throughout data center environments, a thorough floor mat protection system serves as your first line of defense against static electricity and contamination. You'll need a combination of specialized mats to create extensive protection for your sensitive equipment and workspace.

Start with entrance mats at doorways to capture dirt and moisture from shoes before they enter critical areas. Install high-performance absorbent mats in high-traffic zones to minimize slip hazards and maintain cleanliness. These specialized mats help reduce maintenance costs by preventing equipment damage from static discharge.

For areas where you're handling electronic components, you'll want ESD mats that provide a properly grounded surface for hardware assembly and repairs.

Consider implementing dual-mat systems that combine scraper and absorbent functions for maximum protection. Choose mats made from durable materials like nitrile rubber, and guarantee they include drainage holes if you're placing them in areas prone to moisture.

When integrating with anti-static flooring, select mats that complement your existing ESD protection system while maintaining ANSI/ESD compliance.

Don't forget to regularly inspect and maintain your mat system. You'll want to guarantee proper grounding connections on ESD mats and verify that all mats remain firmly in place to prevent tripping hazards while maintaining their protective functions.

Anti-Static Device Management

A thorough anti-static device management strategy is essential for protecting your data center's sensitive electronic equipment. You'll need to implement multiple layers of protection, starting with ESD flooring that provides a safe path for static charges to dissipate. This flooring solution allows you to operate your facility across various temperature and humidity levels while maintaining effective static control. User activities like removing clothing or standing from chairs can generate voltages above 6 kV.

Equip your technicians with essential static control tools, including wrist straps connected to common ground points and ESD table mats for hardware assembly and repair work.

You'll want to replace standard plastic items with ESD-safe alternatives to minimize static buildup throughout your facility. Remember that electrostatic attraction can cause dust to accumulate on charged surfaces, potentially leading to hardware failures.

Maintain your anti-static measures through regular cleaning and maintenance. Create detailed checklists and schedule quarterly cleaning sessions at minimum. You'll need to use appropriate cleaning supplies and techniques to prevent equipment damage.

Choosing Static Dissipative Products

Static dissipative products play a vital role in protecting sensitive data center equipment from electrostatic discharge. When selecting these products, you'll need to focus on solutions that offer permanent static-resistant properties, regardless of environmental conditions or wear patterns. Damage to sensitive components can occur from discharges as low as 25 volts or less.

Start with your flooring choice, as it's the foundation of your ESD control strategy. While high-pressure laminate (HPL) might seem cost-effective, it can generate over 2000 volts of static.

Instead, opt for static-dissipative carpet or ESD static dissipative coatings that provide balanced conductivity and resistance. You'll want to guarantee your chosen flooring remains groundable after installation and doesn't require special footwear for effectiveness.

For cleaning supplies, invest in ESD vacuum cleaners equipped with HEPA filters and lint-free wipes that won't generate additional static during maintenance. Don't forget particle-absorbent dust cloths for routine cleaning.

When maintaining your static dissipative products, avoid sweeping, which can create airborne particles. Instead, use ESD-approved mops or vacuums that meet ANSI/ESD standards.

Remember that your static control strategy should extend beyond just flooring – consider ESD-controlled seating and appropriate footwear to create an extensive protection system.

Proper Cleaning Material Storage

You'll need a temperature-controlled supply room to properly store your data center cleaning materials, as extreme temperatures can compromise chemical effectiveness and container integrity.

Make sure you're following chemical compatibility guidelines by storing reactive substances separately and using appropriate container materials for each cleaning agent.

Implement secure access protocols to guarantee only authorized personnel can access cleaning supplies, while maintaining detailed inventory records of all materials stored in the facility. A proper storage ventilation system must be installed to prevent dangerous fumes from accumulating in enclosed spaces.

Temperature-Controlled Supply Rooms

Inside modern data centers, temperature-controlled supply rooms play a critical role in maintaining cleaning material integrity. You'll need to guarantee these spaces maintain consistent temperature and humidity levels while protecting your cleaning supplies from environmental factors that could compromise their effectiveness. Following ASHRAE recommendations, supply rooms should maintain 18°C to 27°C for optimal storage conditions.

Set up your storage room with proper ventilation systems and fire suppression equipment to prevent hazardous situations. You'll want to implement restricted access controls and maintain clear labeling for all materials to guarantee safety protocols are followed.

| Environmental Factor | Required Control |

|---|---|

| Temperature | Maintain stable range |

| Humidity | Monitor and regulate levels |

| Air Quality | Install ventilation systems |

Your storage room should include proper shelving and organization systems to prevent mixing incompatible materials. Don't forget to implement regular inventory management practices – rotate stock, track expiration dates, and maintain appropriate stock levels. You'll need to conduct routine inspections of your pest control measures and guarantee all equipment is properly maintained.

Remember to establish cleaning schedules and maintain detailed documentation of all maintenance activities. Regular air quality monitoring will help you detect any harmful fumes before they become problematic, keeping your cleaning supplies in ideal condition.

Chemical Compatibility Guidelines

Proper chemical compatibility represents a cornerstone of data center maintenance safety. You'll need to select cleaning chemicals that are specifically approved for data center use, focusing on non-ammoniated and ESD dissipative solutions that won't damage your sensitive equipment.

When choosing cleaning agents, verify they're qualified by computer manufacturers or certified as equipment-neutral to maintain hardware integrity.

Store your cleaning supplies in a dedicated area away from critical equipment to prevent cross-contamination. It's crucial to keep all chemicals in their original containers with clear labels, and you shouldn't store them alongside cardboard, paper products, or standard office supplies. Limit the quantity of cleaning materials kept in the data center to reduce spill risks.

You'll want to handle these chemicals with extreme care. Never spray cleaning solutions directly onto equipment – instead, apply them to wipes or cloths first.

Keep your cleaning tools separate from those used in other building areas, and make sure you're following a detailed checklist for each cleaning task.

Regular reviews of your chemical compatibility guidelines will help you stay aligned with current industry standards and protect your valuable equipment.

Secure Access Protocols

Secure storage and controlled access of cleaning materials form the foundation of data center safety protocols. You'll need to establish dedicated storage areas outside the data center facility, equipped with proper locking mechanisms and clear labeling. Guarantee these areas maintain adequate ventilation to prevent the buildup of chemical vapors.

To maintain strict access control, you must limit cleaning supply access to trained and authorized personnel only. Implement a sign-in process requiring proper identification, and schedule access during specific timeframes.

When handling supplies, you'll need to keep them in sealed containers and transport them safely following manufacturer guidelines.

Don't forget to prepare for emergencies by developing thorough response protocols. You'll want to maintain a well-documented spill response plan and keep first aid supplies readily available.

Regular emergency drills will help your team stay prepared for potential incidents.

Remember to conduct routine inspections of your storage areas to check for leaks or contamination. Track expiration dates of cleaning supplies and guarantee they're used under proper supervision.

These measures will help protect both your data center equipment and personnel while maintaining a secure cleaning supply management system.

Static Control Maintenance Schedule

Static control in data centers requires a thorough maintenance schedule that addresses daily, quarterly, and specialized cleaning needs.

You'll need to implement daily protocols including monitoring humidity levels, using anti-static mats, and confirming proper grounding of all equipment. Make sure your staff consistently uses wrist straps and cleans surfaces with appropriate anti-static solutions.

Your quarterly maintenance should focus on detailed visual inspections. You'll want to check for dust buildup, examine anti-static components for wear, and verify that equipment racks maintain proper grounding. Document all your inspection findings and maintenance work using a meticulous tracking system.

Maintain the best environmental conditions by keeping humidity levels between 40-60%. You'll need to utilize humidification systems and monitor temperature levels to prevent static-inducing conditions. Install redundant cooling systems to guarantee consistent environmental control.

Hire specialized cleaning services twice yearly for professional-grade maintenance. They'll use lint-free cleanroom wipes, wear appropriate gloves, and apply static-reducing solutions to your floors. Confirm these professionals are properly trained in data center cleaning protocols and understand the importance of maintaining a cleanroom environment.

Equipment-Specific Cleaning Solutions

For effective data center maintenance, you'll need specialized cleaning solutions tailored to different types of equipment. Your cleaning agents must be ESD dissipative to prevent static buildup while handling sensitive components. Choose non-residue cleaners that won't leave behind traces that could affect equipment performance or attract dust.

When cleaning equipment surfaces, you'll want to use special dust cloths designed with particle absorbent materials, particularly for intricate parts and components.

Control humidity levels during the cleaning process to prevent moisture-related damage to your equipment. Don't use standard commercial cleaners; instead, opt for specialized cleaning agents specifically formulated for data center equipment.

You'll need to maintain proper airflow by regularly removing dust and debris using HEPA-filtered vacuum cleaners. Make sure you're organizing cables effectively to facilitate thorough cleaning and reduce accident risks.

For underfloor areas, use specialized tools designed to reach confined spaces and maintain ventilated floor systems. Remember to seal and encapsulate subfloor areas to protect against dust and moisture infiltration.

Consider working with specialized cleaning teams who understand the unique requirements of data center environments.

Environmental Monitoring During Cleaning

Environmental monitoring serves as the backbone of effective data center cleaning operations. You'll need to maintain strict control over air quality, temperature, and humidity levels to protect your equipment during cleaning procedures.

Installing environmental monitoring systems (EMS) with strategically placed sensors will help you detect potential issues before they become problems.

You should integrate your sensors into a digital framework that feeds into a central management repository. This setup allows you to track real-time data on temperature, humidity, and air quality, enabling quick responses to any environmental changes during cleaning activities.

It's essential to program early-warning alerts for humidity levels at 40% and 60% to prevent static discharge and condensation issues.

Keep detailed records of environmental conditions and maintain a regular calibration schedule for your HVAC systems and sensors. When cleaning, you'll want to use lint-free, non-shedding materials to prevent particulate buildup.

Make sure you've integrated your EMS with your data center infrastructure management (DCIM) software for thorough oversight.

Following a well-documented concept of operations (CONOPS) will guarantee your team responds appropriately to sensor readings and maintains ideal environmental conditions throughout the cleaning process.

Safe Handling of Cleaning Supplies

Safe handling of cleaning supplies begins with proper storage and organization of your data center maintenance products. You'll need to establish dedicated storage areas where daily-use items are easily accessible, while keeping more hazardous chemicals in locked cabinets.

Store all products in their original containers and organize them based on their active ingredients to prevent dangerous chemical interactions.

You should maintain a detailed inventory of your cleaning supplies and implement a system to track when products need replacement. For your data center's protection, don't use cleaning equipment from other areas of the building – keep dedicated supplies for your data center to prevent cross-contamination.

When you're using cleaning solutions, apply them sparingly near equipment and guarantee proper disposal away from sensitive hardware.

Create and follow a thorough checklist that outlines approved chemicals and tools for your cleaning staff. You'll want to establish clear protocols for handling different types of cleaning supplies, from gentle surface cleaners to more potent solutions.

Remember to clean vacuums outside the building and rinse equipment away from data center infrastructure to maintain a contamination-free environment.

Personnel Training for Static Prevention

Building upon proper cleaning protocols, static prevention requires focused personnel training to protect sensitive data center equipment. You'll need to implement a thorough static awareness training that educates your staff about ESD risks and their potential impact on electronic components.

Train your team to properly use essential ESD prevention tools, including wrist straps, anti-static mats, and static-resistant footwear.

Make sure your personnel understand the importance of wearing appropriate PPE, including anti-static clothing and ESD-safe accessories. You should require them to consistently use wrist straps with built-in resistors when handling sensitive equipment.

Teach safe movement practices that minimize static generation within designated static control areas.

Establish regular refresher courses to maintain high awareness levels and guarantee compliance with ESD prevention protocols. Your training program should emphasize proper cable management techniques and the correct use of ESD-safe cleaning supplies.

Include practical demonstrations of grounding techniques and equipment checks in your training sessions. By teaching your staff to identify and mitigate ESD risks effectively, you'll create a safer environment for your data center's sensitive components.

Frequently Asked Questions

How Often Should Sticky Floor Mats Be Replaced in Data Centers?

You'll need to replace sticky floor mats when they're visibly dirty or lose tackiness. Check them each shift and replace the top sheet, but adjust your replacement frequency based on traffic volume and contamination levels.

Can Regular Household Vacuum Cleaners Be Modified for Data Center Use?

You shouldn't modify household vacuums for data center use. They lack proper HEPA filtration and anti-static properties. Instead, you'll need to invest in specialized data center vacuums to protect your sensitive equipment.

What Temperature Should Cleaning Supplies Be Stored at for Optimal Effectiveness?

You'll want to store your cleaning supplies between 64-81°F (18-27°C) in a cool, dry space. This temperature range maintains their effectiveness while preventing hazardous chemical reactions and deterioration of the products.

Do Electromagnetic Fields From Equipment Affect the Efficiency of Antistatic Cleaners?

Yes, electromagnetic fields will impact your antistatic cleaners' effectiveness by interfering with ionization processes and causing static to rebuild faster. You'll need shielded tools and more frequent cleaning to maintain proper static control.

How Does Altitude Affect Static Buildup in Data Center Environments?

At higher altitudes, you'll experience more static buildup in your data center due to lower humidity and air pressure. This increases your risk of ESD, requiring enhanced static control measures and proper humidification.

In Summary

Keep your data center's cleanliness and static control as top priorities. You'll need to regularly check your cleaning supplies' effectiveness and train your staff on proper antistatic procedures. Don't forget to store your materials correctly and monitor environmental conditions during cleaning sessions. By following these guidelines and maintaining a strict cleaning schedule, you'll protect your valuable equipment from static damage.

Leave a Reply