Humidity levels directly affect how static electricity builds up in your environment. When you're in a low-humidity area (below 40% RH), electrons transfer more easily between materials, creating those annoying static shocks. Higher humidity introduces water molecules into the air that act as natural conductors, helping dissipate static charges before they accumulate. You'll want to maintain relative humidity between 40-60% to effectively control static electricity in most settings. This sweet spot prevents both excessive static buildup and potential moisture damage to sensitive equipment. Understanding the relationship between humidity and static control can help you create safer, more comfortable environments.

Understanding Static Electricity Formation

Static charge, a common workplace nuisance, develops when electrons transfer between materials through contact, separation, or friction. When you bring two materials together, one material loses electrons while the other gains them, creating an imbalance known as the triboelectric effect.

The material that loses electrons becomes positively charged, while the material gaining electrons becomes negatively charged. Static discharge occurs when these charged materials come in contact with conductive surfaces like doorknobs.

You'll find that different materials have varying tendencies to gain or lose electrons, as shown in the triboelectric series. For example, if you rub acetate against another material, it's likely to gain a charge more readily than glass. The amount of static buildup you experience also depends on the material's composition and surface area. Notably, some materials like hard rubber can become either positively or negatively charged depending on what you rub them against.

The process intensifies through repetition – the more you create friction or separate materials, the greater the static charge becomes. You'll notice this effect is particularly strong in low-humidity environments, as moisture typically helps dissipate surface charges.

Temperature changes can also affect static buildup, especially when you're cooling insulating materials.

The Science Behind Humidity Control

When you increase humidity in the air, water molecules become more abundant and move freely between surfaces, creating pathways for static charges to disperse.

You'll find that these water molecules act as natural conductors, allowing electrons to transfer more efficiently and prevent the buildup of static electricity.

Surface charges dissipate more quickly in humid conditions because the moisture creates a thin, invisible film that promotes continuous charge distribution rather than concentrated spots of static buildup. Relative humidity above 55% creates ideal conditions where static electricity cannot accumulate.

Molecular Movement in Air

To understand humidity control, you must first grasp how water molecules move through air. Water vapor's behavior follows specific principles governed by temperature, pressure, and molecular interactions.

When you're dealing with humidity, you're actually managing the concentration of water vapor molecules in the air, measured as relative humidity (RH).

Temperature plays a vital role in this molecular dance. As air gets warmer, it can hold more water vapor, raising the saturation point. This explains why you'll often notice condensation forming on cold surfaces – the water molecules slow down and cluster together when they hit cooler temperatures.

The pressure in your environment also affects how these molecules move, with higher pressure increasing the water vapor's partial pressure. Similar to AIE molecules in sensors, these water molecules respond dynamically to environmental conditions.

The interaction between molecules becomes particularly important in static control applications. Water molecules in the air create a delicate balance between evaporation and condensation. These molecules are constantly in motion, influenced by intermolecular forces that are stronger in liquids than in gases.

You'll find that maintaining proper humidity levels depends on managing these molecular movements through careful temperature and pressure control.

Surface Charge Disbursement Effects

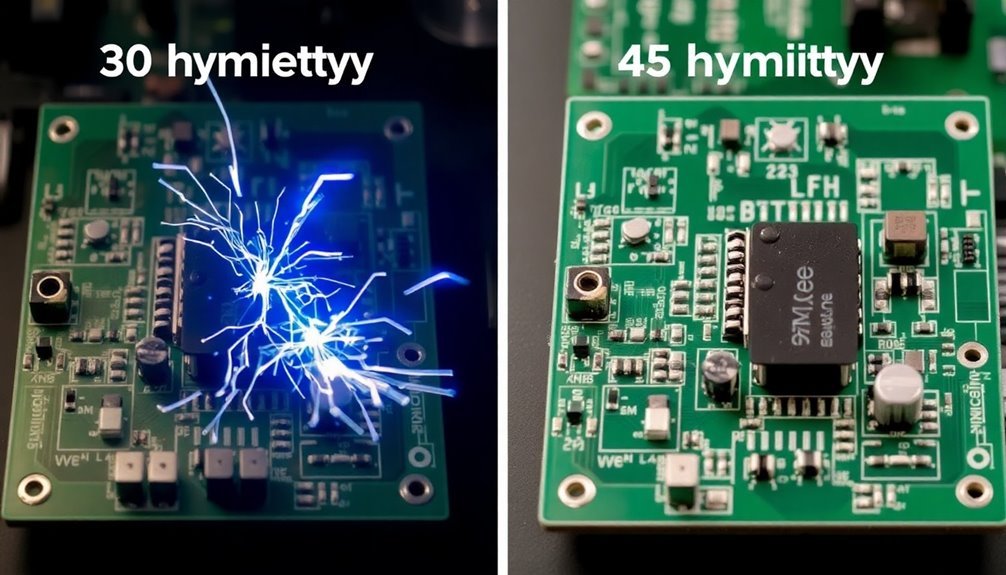

Diving into the science of surface charge disbursement, you'll find that humidity plays a crucial role in managing static electricity. When relative humidity rises above 30%, water molecules in the air create natural pathways for static charges to dissipate, preventing sudden discharges that could damage sensitive equipment or cause discomfort.

Low conductivity materials are especially vulnerable to static electricity buildup, making proper humidity control essential.

You'll notice that static charge behavior follows a predictable pattern based on humidity levels:

- At less than 40% RH, static charges build up rapidly and remain persistent on surfaces

- Between 40-70% RH, charges disperse naturally through water molecules in the air

- Above 70% RH, charge dissipation is highly efficient but risks corrosion of electronics

- At ideal levels (30-70% RH), static charges spread across numerous water droplets, reducing shock risks

The triboelectric effect, which generates static electricity through material contact, becomes less problematic in humid conditions. This is because moisture increases air conductivity, allowing charges to decay more quickly.

If you're working with sensitive electronics or in static-sensitive environments, you'll want to maintain humidity levels between 30-70% for effective static control while avoiding moisture-related damage.

Optimal Humidity Ranges

The ideal humidity range for static control typically falls between 30% and 70% relative humidity (RH), with most electronics manufacturing environments maintaining around 50% RH.

Keeping humidity above 30% is particularly important in ESD protective areas, as it helps reduce electrostatic charges that can damage sensitive components.

When you're working with electronics, you'll want to avoid exceeding 70% RH, as this can lead to corrosion on metal components.

If you're dealing with domestic environments, maintaining RH above 40% will help reduce static electricity in your home. Once you reach levels above 55% RH, you'll completely prevent static buildup.

While humidity helps control static, it isn't considered a primary ESD control measure. Your ESD control items must still function effectively at humidity levels as low as 12% ± 3% RH at 23°C ± 3°C.

If you're involved in specific processes like soldering, you'll need to pay special attention, as high humidity levels above 70% can interfere with these operations.

For most industrial applications, you can maintain ideal static control by keeping RH between 30% and 70%. Charge generation significantly drops from 35kV at 10% RH to just 7.5kV at 55% RH, demonstrating humidity's effectiveness in static reduction.

Data Center Humidity Requirements

You'll need to maintain data center humidity between 40-60% to prevent both static discharge at low levels and corrosion at high levels.

Your monitoring setup must include properly spaced temperature and humidity sensors every 3-9 meters, with alerts configured for when levels reach 30% or 70%.

To control humidity effectively, you should integrate your monitoring systems with cooling equipment and implement proper humidification solutions like adiabatic evaporative systems that align with ASHRAE guidelines. Setting a dew point of 5.5°C helps prevent damaging condensation from forming on equipment.

Optimal Humidity Range Targets

Maintaining precise humidity levels stands as a critical requirement for data center operations, with ASHRAE guidelines recommending a target of 50% relative humidity. You'll want to keep your facility's humidity between 45% and 55% for ideal equipment performance, though the allowable range extends from 20% to 80%. Most data centers house A1 and A2 equipment that requires strict adherence to these humidity parameters.

For effective static control, you'll need to monitor these critical dew point parameters:

- Base temperature range of -9 to 15 degrees C (15.8 to 59 degrees F) for standard A1 to A4 equipment

- Extended allowable range of -12 to 24 degrees C (10.4 to 75.2 degrees F) for specialized scenarios

- Maximum change rate of 5 degrees C per 20-hour period to prevent thermal shock

- Upper moisture threshold of 60% RH in environments with copper and silver components

You should implement an early warning system that triggers alerts at 40% and 60% humidity levels, with critical alerts set for 30% and 70%.

Essential Monitoring Equipment Needed

To properly monitor and maintain the target humidity ranges discussed above, you'll need an extensive set of monitoring tools. Advanced humidity sensors and hygrometers are essential components that provide continuous readings of moisture content in your data center's air. These devices work alongside temperature sensors to deliver a thorough environmental monitoring data.

You'll want to integrate your monitoring equipment with your HVAC systems for ideal control. Modern systems like Monnit Wireless Humidity Sensors can connect to your existing infrastructure, offering real-time data and immediate alerts when conditions deviate from acceptable ranges.

The system's IoT capabilities let you manage and monitor conditions remotely through online software platforms.

For maximum effectiveness, you'll need remote monitoring solutions that include features like SensGuard, which tracks ambient room temperature and relative humidity near your server racks. These systems should offer multi-level access rights and customizable alerting options via email or SMS.

Don't forget to implement interactive mapping capabilities for quick problem identification and maintain regular calibration schedules to keep your monitoring equipment accurate and reliable over time.

Best Practices for Control

Inside modern data centers, maintaining precise humidity levels between 45% and 55% relative humidity (RH) stands as a critical requirement for ideal equipment performance and longevity. You'll need to implement robust control strategies that account for both high and low humidity risks, as either extreme can severely impact your equipment's reliability.

To effectively manage humidity levels in your data center, you should establish these critical control measures:

- Set up real-time monitoring systems with alerts at 40% and 60% RH, giving you adequate time to respond before reaching critical thresholds of 30% and 70%.

- Install strategically placed HVAC units to maintain consistent airflow distribution and prevent humidity-related hot spots.

- Maintain dew point temperatures between -9°C and 15°C to prevent condensation on sensitive equipment.

- Implement regular HVAC maintenance schedules, including calibration of humidity sensors and cleaning of air handling units.

Remember to tailor your humidity control approach based on your local climate conditions. If you're in an arid region, focus on humidification systems; in humid climates, prioritize dehumidification capabilities.

This targeted strategy will help you maintain ideal conditions while maximizing energy efficiency.

Measuring Humidity Effectively

When managing static control in any environment, accurate humidity measurement becomes a vital first step. You'll find several reliable methods to monitor your facility's humidity levels, each offering distinct advantages. Electronic hygrometers provide convenient, continuous monitoring with reasonable accuracy of +2-5% RH, making them ideal for most static control applications. If you need laboratory-grade precision, dew point measuring devices deliver superior accuracy, though they require more maintenance.

For ongoing monitoring, you might consider psychrometers, which use wet and dry bulb temperatures to calculate relative humidity. While they demand proper airflow for accurate readings, they're particularly reliable in industrial settings. In specialized applications where trace moisture measurement is essential, oscillating quartz crystal sensors offer targeted precision.

| Method | Accuracy | Best Use Case |

|---|---|---|

| Electronic Hygrometer | +2-5% RH | General monitoring |

| Psychrometer | +2-5% RH | Industrial environments |

| Dew Point Device | Highest | Laboratory standards |

| Quartz Crystal | +10% | Trace moisture detection |

Choose your measurement method based on your specific needs, considering factors like required accuracy, maintenance capabilities, and environmental conditions.

Industrial Applications and Solutions

A wide range of industries relies on effective humidity control to combat static electricity problems. From packaging and printing to electronics and pharmaceuticals, maintaining humidity levels above 55%RH naturally prevents static buildup by allowing charges to dissipate through moisture in the air.

You'll find several humidification solutions available for industrial settings:

- Direct room humidifiers that maintain overall environmental moisture

- Localized spray systems that target specific areas or machinery

- Dry fog systems that offer precise control without wetness concerns

- Saturated salt solutions for specialized environmental needs

When you're implementing humidity control in your facility, you'll need to evaluate potential challenges. Heat from machinery can create dry air pockets that compromise humidity effectiveness, while excessive moisture might lead to condensation and equipment rust.

You'll want to balance these factors carefully, especially around sensitive equipment.

The right humidity control solution can dramatically improve your operations. You'll see fewer static-related production issues, enhanced safety conditions, and better product quality.

While steam systems are common, you might find that newer technologies like dry fog offer more efficient solutions with lower energy consumption and fewer maintenance requirements.

Home Prevention Methods

Managing static electricity at home requires a multi-faceted approach that combines proper humidity control with smart material choices. You'll find that installing a home humidifier is one of the most effective solutions, as it helps maintain the ideal humidity level of around 55%RH.

Whether you opt for a whole-house system that works with your HVAC or a portable unit, proper humidity control will substantially reduce static buildup.

Your choice of materials plays a vital role in static prevention. Choose natural fibers like cotton or wool over synthetic materials, as they're less likely to generate static electricity.

You can further reduce static by using fabric softeners and dryer sheets on your clothing and carpets. For additional humidity control, consider placing moisture-loving plants like peace lilies or ferns throughout your home, as they'll naturally release moisture into the air.

Don't forget to monitor your home's humidity levels using a hygrometer to prevent over-humidification. You'll need to maintain proper ventilation through extraction fans in bathrooms and kitchens while ensuring adequate air circulation.

Regular maintenance of your humidifiers and ventilation systems will help you maintain the best humidity levels without risking mold growth.

Frequently Asked Questions

Can Static Electricity Affect the Accuracy of Electronic Measuring Instruments?

Yes, static electricity can throw off your measurements substantially. You'll find it interferes with electronic instruments by creating unwanted forces, causing inaccurate readings and potential damage to sensitive measuring components.

How Quickly Does Static Electricity Dissipate When Humidity Levels Increase?

You'll notice static electricity dissipates much faster as humidity rises. When relative humidity increases, your static charges will scatter more quickly due to increased air conductivity and accelerated charge leakage through moisture particles.

Do Air Ionizers Work Better Than Humidifiers for Controlling Static?

You'll find air ionizers work better than humidifiers for static control since they're more versatile, can neutralize charges directly, and work effectively in any environment, while humidifiers only function within specific humidity ranges.

What Materials Are Most Susceptible to Static Buildup in Low Humidity?

You'll find plastics and synthetic textiles are most prone to static buildup in dry conditions. Non-conductive polymers, synthetic clothing fibers, and dry wood will also readily accumulate static charges in low humidity environments.

Does the Time of Day Affect Static Electricity Formation?

You'll notice static electricity forms independently of time but is influenced by daily temperature and humidity changes. Your heating and cooling systems can create drier conditions that increase static build-up throughout the day.

In Summary

You'll find managing humidity is essential for preventing static electricity damage in both professional and home environments. By maintaining relative humidity between 30-60%, you're creating an environment where static charges can't easily build up. Whether you're protecting sensitive electronics or preventing uncomfortable shocks, proper humidity control isn't just about comfort – it's vital for safeguarding your equipment and creating a safer space.

Leave a Reply