You'll want to store your anti-static bags between 21°C to 23°C (70°F to 73°F) for ideal protection, though they can handle operational temperatures from 15°C to 25°C (59°F to 77°F). Don't let them exceed 37.8°C (100°F), as this can lead to material degradation. While these bags are surprisingly resilient – with anti-static polyethylene withstanding up to 115°C and metal-in varieties up to 149°C – maintaining proper storage temperatures guarantees their two-year shelf life. Watch for signs like yellowing, brittleness, or delamination, as these indicate it's time for replacement. Understanding the full scope of temperature limits can help maximize your ESD protection investment.

Optimal Storage Temperature Range

Anti-static bags' perfect storage temperature typically ranges from 21°C to 23°C (70°F to 73°F), with a wider acceptable range between 15°C to 25°C (59°F to 77°F) for most products.

You'll need to guarantee that storage temperatures never exceed 100°F (37.8°C), as high temperatures can greatly degrade the material properties and reduce the effectiveness of your anti-static bags. The FDA approved material ensures safety and compliance during storage and handling.

You should store your bags away from direct sunlight, as ultraviolet rays can cause oxidation of the aluminum shielding layer. This protection is vital since UV exposure, combined with heat and moisture, can compromise the bag's integrity and protective properties. The bags provide excellent EMI/RFI protection when properly stored and maintained.

While some products can be stored at 76°F (24°C), it's best to maintain the lower recommended range whenever possible.

For best performance and longevity, you'll want to monitor your storage environment carefully. Proper temperature control is important for maintaining the bag's resistance to tribocharging and static discharge.

When you store your anti-static bags under perfect conditions, you can expect them to maintain their functionality throughout their two-year shelf life, guaranteeing reliable protection for your sensitive electronic components.

Heat Impact on ESD Materials

The thermal properties of ESD materials play an essential role in their performance and longevity. When you're working with anti-static bags, you'll need to understand how heat affects their protective qualities. The metal-in film laminate, measuring 2.8 mils thick, provides thermal stability, but it's vital not to exceed the temperature limits of these materials. For optimal sealing performance, these bags require 30 to 70 PSI during heat application.

While anti-static bags can withstand heat-sealing processes, you shouldn't expose them to temperatures above their melting points. LDPE components begin to melt between 221°F and 239°F, while polyester/polyethylene/metal laminates can handle temperatures up to 375°F. The SCS 1000 Series bags are specifically designed to withstand these high-temperature conditions. Direct sunlight and excessive heat can compromise the aluminum layer's integrity and reduce the bag's static shielding capabilities.

- Maximum operating temperature shouldn't exceed 275°F (135°C)

- Surge temperatures must stay below 300°F (149°C)

- Storage temperatures should remain under 100°F (38°C)

The bags maintain their Faraday cage effect and ESD protection properties when used within these temperature ranges. However, exceeding these limits can lead to material degradation and compromise the bag's ability to protect sensitive electronic components from electrostatic discharge.

Cold Weather Storage Guidelines

Proper storage of ESD bags in cold weather requires careful attention to temperature control and environmental conditions. While anti-static bags don't have explicit cold weather storage guidelines, you'll want to maintain temperatures between 21°C to 23°C to guarantee peak performance and longevity.

Although these bags are made from resilient materials like polyester and polyethylene that don't notably degrade at low temperatures, it's best to keep them within their operational temperature range of 15°C to 25°C. You shouldn't assume that because metal-in static shielding bags can handle high operational temperatures (149°C to 190°C), they're equally suitable for extreme cold storage.

To protect your anti-static bags during cold weather, you'll need to store them in a controlled environment away from moisture and direct sunlight.

Remember that proper storage conditions will help maintain the bags' effectiveness in protecting ESD-sensitive devices throughout their 2-year shelf life. While the bags' materials don't show specific cold-weather vulnerabilities, it's safest to store them at room temperature to preserve their static shielding properties and prevent any potential material stress from temperature extremes.

Temperature Monitoring Best Practices

Building on cold weather storage guidelines, implementing a robust temperature monitoring system helps maintain the integrity of anti-static bags throughout their lifecycle.

You'll need to maintain storage temperatures between 21°C to 23°C, while guaranteeing operational temperatures stay within 15°C to 25°C (59°F to 77°F). For static shielding bags, you shouldn't exceed the maximum operating temperature of 300°F (149°C).

When monitoring temperatures, you'll want to pay special attention to different material types. Polyethylene materials work best within 15°C to 25°C, while Metal-In static shielding can handle higher temperatures between 149°C to 190°C.

It's vital to implement regular temperature checks and maintain proper documentation for compliance with standards like ANSI/ESD S20.20 and IEC 61340-5-1.

- Set up temperature monitoring stations in storage areas with automated alerts when readings fall outside acceptable ranges

- Keep detailed logs of temperature readings and any corrective actions taken to maintain compliance

- Regularly calibrate temperature monitoring equipment to guarantee accurate readings across all storage and handling areas

Remember to avoid direct sunlight exposure and maintain proper grounding procedures while handling bags in temperature-controlled environments.

Signs of Temperature Damage

You'll need to carefully inspect your anti-static bags for visible signs of temperature damage, including surface irregularities like cracks, tears, or wrinkles that indicate compromised integrity.

When examining the bag's layers, look for any separation between the material components, which often appears as bubbling or delamination of the protective layers.

The appearance of yellowing, browning, or physical warping serves as a clear warning that your anti-static bags have been exposed to temperatures beyond their acceptable limits.

Physical Surface Changes

Three key physical changes signal temperature damage in anti-static bags: discoloration, brittleness, and deformation.

You'll notice the bag's surface becoming less transparent or taking on a yellowish tint when it's been exposed to high temperatures. The material may also become fragile and prone to cracking, making it unreliable for protecting sensitive electronics.

Temperature damage isn't always immediately obvious, but you can spot it through careful inspection. When your anti-static bags have been compromised by heat exposure, you'll see a significant reduction in clarity and possible surface cracking. These changes aren't just cosmetic – they indicate that the bag's protective properties may be compromised.

- Look for warping or changes in the bag's original shape, which signals heat damage

- Check for reduced transparency or yellowing, especially in areas that were previously clear

- Examine the surface for small cracks or signs of brittleness, particularly along folds

If you spot any of these physical changes, it's time to replace your anti-static bags.

Remember that proper storage below 100°F (38°C) will help prevent these issues and maintain the bags' protective qualities.

Material Layer Separation

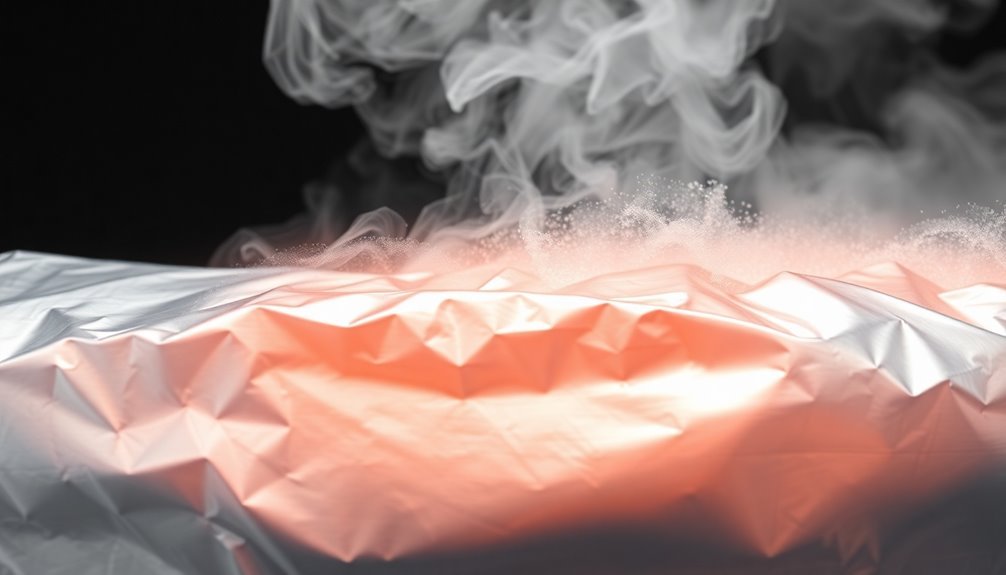

Material layer separation poses a critical threat to anti-static bags when exposed to excessive temperatures.

When your anti-static bags experience thermal stress, you'll notice several warning signs that indicate compromised protection. Delamination, the loss of bond between layers, can occur, leading to reduced ESD shielding capabilities.

You might also spot blisters, which appear as air pockets trapped between the material layers. Watch for peeling or flaking of the metalized layer, as this directly impacts the bag's ability to protect your electronic components.

Cracks may develop across the surface, creating vulnerable points where static charges can build up. If you notice adhesion failure, where layers no longer stick together properly, your bags won't provide reliable protection.

You'll need to conduct regular visual inspections to catch these issues early. Test the bag's tensile strength and surface resistivity to verify it still meets protection standards.

Discoloration and Warping

Over time, excessive heat exposure leaves telltale signs of damage on anti-static bags through discoloration and warping.

You'll notice color changes as your bags deteriorate, with transparent materials becoming hazy or opaque. The aluminum layer in metal-in bags can oxidize, while plastic components may turn yellow or brown, indicating serious chemical degradation. Most anti-static bags have a maximum temperature limit of 150°C before permanent damage occurs. Static discharge protection is essential for preventing costly repairs and replacements of sensitive electronics.

Warping poses another significant threat to your anti-static bags' effectiveness. When exposed to high temperatures, bags can shrink, expand, or become distorted, compromising their protective properties.

You'll find that overheated bags become stiff and brittle, making them more susceptible to cracks and breaks. The heat can also damage the seals, leaving your sensitive components vulnerable to moisture and static charge.

- Watch for printed symbols becoming distorted or illegible – this is a clear sign that your bag has been exposed to damaging temperatures.

- Check for dimensional changes and seal integrity, especially if bags have been stored above 76°F (24°C).

- Monitor for changes in material flexibility, as stiffness indicates heat-related deterioration that can compromise static protection.

Seasonal Storage Considerations

Proper seasonal storage of anti-static bags requires careful attention to environmental conditions throughout the year.

You'll need to maintain a consistent temperature of around 24°C (76°F) to protect the aluminum shielding layer from oxidation. While these bags can withstand brief temperature spikes up to 149°C (300°F), you shouldn't expose them to temperatures above 130°C (266°F) for extended periods.

To maximize your bags' 1-2 year shelf life, you'll want to store them away from direct sunlight, as UV rays can degrade the materials.

Keep them in a dry environment to prevent moisture damage, and don't store them near chemicals that could compromise their integrity. You should also avoid placing them near heat sources that could cause warping or deterioration.

Remember to conduct regular inspections of your stored bags to guarantee they're maintaining their protective properties.

If you're storing them in an Electrostatic Protected Area (EPA), verify that the bags still meet static decay requirements of less than 2 seconds.

When you notice signs of deterioration or if the bags have been stored beyond their recommended shelf life, it's time to replace them.

Temperature During Transportation

When transporting anti-static bags, you'll need to maintain temperatures between 59°F and 77°F (15°C to 25°C) to preserve their protective qualities.

Never let temperatures exceed 100°F (37.8°C) during shipping, as this can compromise the bags' effectiveness. It's essential to monitor temperature conditions throughout the transportation process to guarantee your sensitive electronic components remain protected.

You'll want to take extra precautions during transportation by properly packaging the anti-static bags and protecting them from moisture.

Remember that extreme temperature fluctuations can impact the static dissipation performance of the bags, even if they're within the acceptable handling range of -40°C to 60°C.

- Keep bags away from direct sunlight during transit to prevent heat buildup and potential damage

- Package bags with appropriate insulation if you're shipping through areas with extreme temperatures

- Monitor shipping conditions and choose climate-controlled transportation when possible

If you're shipping anti-static bags long distances, consider using temperature monitoring devices to track exposure levels.

While the ESD shielding properties won't considerably change within recommended ranges, prolonged exposure to extreme temperatures can degrade the bags' protective qualities over time.

Climate Control Requirements

You'll need to maintain a steady room temperature of 76°F (24°C) in your storage area, using calibrated thermostats and climate control systems to prevent temperature fluctuations that could compromise the anti-static bags' integrity.

Your daily temperature monitoring should include regular checks using digital thermometers at multiple points throughout the storage space, with readings logged at consistent intervals to track any variations.

Setting up automated temperature alerts and installing proper ventilation systems will help you maintain ideal conditions while protecting the bags from harmful UV exposure and moisture.

Optimal Storage Room Setup

The ideal storage room for anti-static bags requires precise climate control to maintain their protective properties. You'll need to keep the temperature between 21°C to 23°C (59°F to 77°F), with a strict maximum limit of 100°F (38°C).

It's vital to position your storage area away from direct sunlight and heat sources to prevent degradation of the bags' protective qualities.

For ESD-safe storage, you'll want to create a dedicated protected area with grounded surfaces to dissipate any electrostatic charges. When setting up your storage room, make sure it's clean and equipped with static dissipative materials.

You should maintain consistent conditions to enhance the bags' two-year shelf life while regularly inspecting them for any signs of damage.

- Install temperature monitoring systems to guarantee readings stay within the ideal 21-23°C range

- Set up your storage racks away from windows and heating/cooling vents to maintain stable conditions

- Create designated ESD-protected zones with proper grounding equipment and static dissipative materials

Remember to check your storage room's conditions regularly and keep detailed records of temperature fluctuations to protect your investment in these specialized materials.

Daily Temperature Monitoring Methods

Building on proper storage room setup, daily temperature monitoring becomes a key factor in protecting your anti-static bags. You'll need to maintain temperatures between 21°C to 23°C, never exceeding 24°C to prevent damage to the aluminum shielding layers. Regular monitoring helps you spot and address temperature fluctuations before they affect bag integrity.

| Monitoring Task | Frequency |

|---|---|

| Check room temperature | Every 4 hours |

| Verify humidity levels | Twice daily |

| Inspect light exposure | Morning/Evening |

| Record temperature logs | Each shift |

| Check HVAC function | Daily |

You'll want to install digital thermometers at different points in your storage area to track temperature variations. Keep detailed logs of your readings, noting any fluctuations that approach the 24°C limit. Don't forget to monitor humidity levels alongside temperature, as both factors work together to affect bag performance. When you notice temperatures rising above 23°C, check your climate control systems immediately and adjust as needed. Remember that consistent temperatures are just as important as staying within the recommended range – sudden changes can be just as damaging as sustained high temperatures.

Testing Temperature Resistance

Testing anti-static bags for temperature resistance carries out under precise environmental conditions, with samples evaluated at 73°F ± 5°F (23°C ± 3°C) and 12% ± 3% relative humidity for a minimum of 48 hours.

The testing process involves multiple measurements to ascertain your bags meet strict ESD control standards. You'll measure surface resistance on both sides of the bag, which shouldn't exceed 1.0 x 10^11 Ω, and volume resistance from the inside to the testing plate.

The bags must also demonstrate proper electrostatic decay, dropping from ±5kV to ±0 volts in under 2.0 seconds.

- Use a concentric ring fixture with a 5-pound probe for consistent pressure during resistance testing

- Monitor charge retention to ensure it stays below 1.0 nC

- Verify static shielding capabilities remain under 20 nJ at both 12% and 50% RH

These tests comply with multiple standards, including ANSI/ESD STM11.11, STM11.12, and the thorough ESD control program standard ANSI/ESD S20.20.

Temperature Related Performance Standards

Understanding anti-static bag performance standards starts with their critical temperature specifications. You'll need to maintain storage temperatures between 21°C and 23°C for peak performance, though the operational range extends from 15°C to 25°C.

The bags will begin to degrade if exposed to temperatures above 37.8°C (100°F).

You can rely on these bags' thermal properties up to their melting point of 105°C to 115°C for anti-static polyethylene, while metal-in static shielding bags offer higher temperature resistance up to 149°C.

You'll find that the bags maintain their ESD protection properties effectively when kept within the operational temperature range of 59°F to 77°F.

To verify compliance with industry standards, you'll want to ensure that your anti-static bags meet ANSI/ESD S20.20 and IEC 61340-5-1 requirements.

These standards guarantee proper static dissipation and material stability within the specified temperature ranges.

The bags' performance directly relates to their temperature exposure – they'll maintain seal integrity and static dissipation properties when used within recommended ranges but may experience performance degradation outside these limits.

Frequently Asked Questions

Can Anti-Static Bags Be Reused After Exposure to Freezing Temperatures?

You shouldn't reuse anti-static bags after freezing exposure. While they may look fine, freezing can compromise their static-dissipative properties and make them brittle. It's safer to use new bags for sensitive electronics.

Do Different Colored ESD Bags Have Varying Temperature Tolerances?

No, your ESD bag's color doesn't affect its temperature tolerance. The material composition, not the color, determines how much heat it can handle. All bags made from the same material have identical temperature limits.

How Quickly Do Anti-Static Bags Recover From Temporary Temperature Fluctuations?

You won't find specific data on anti-static bags' recovery speeds from temperature changes. While they're designed to handle operational ranges of 15-25°C, it's best to maintain consistent storage temperatures for ideal performance.

Does Altitude Affect the Temperature Resistance of Anti-Static Bags?

While there's no direct evidence that altitude affects your anti-static bags' temperature resistance, you should still monitor them closely since high-altitude environments may expose materials to increased UV radiation and different humidity levels.

Can Static Shielding Properties Change if Bags Experience Rapid Temperature Cycling?

Yes, while your static shielding bags maintain their Faraday cage effect, rapid temperature cycling can weaken the material's integrity over time, though the actual static dissipative properties typically remain within acceptable operational ranges.

In Summary

You'll get the best performance from your anti-static bags by keeping them within recommended temperature ranges and monitoring them regularly. Don't expose them to extreme heat or cold, as this can compromise their ESD protection. If you're shipping or storing sensitive components, make sure you've got proper climate controls in place. Test your bags periodically and replace them if you notice any signs of temperature-related damage.

Leave a Reply