Your ion generator won't work properly due to several common issues you can check. First, verify your power supply and fuse are functioning correctly at 220V/50Hz. Next, inspect the unit's positioning and airflow, as poor placement or blocked vents reduce effectiveness. Environmental factors like high humidity (above 60%) or excessive particulate matter can severely impact performance. Regular maintenance is essential – clean emitter points with isopropyl alcohol and guarantee proper grounding. Don't ignore unusual odors or sounds, as they indicate potential problems. Understanding these fundamentals will help you maximize your ion generator's effectiveness and extend its lifespan.

Common Ion Generator Problems

Your ion generator may not be delivering the air purification results you'd expect. The fundamental issue is that these devices don't actually remove particles from your air – they simply charge them electrically and force them to stick to nearby surfaces.

Once these particles lose their charge, they'll become airborne again, continuing the cycle of ineffective air cleaning. Studies show that ground-level ozone produced by these devices can worsen respiratory conditions.

You'll notice particular problems in humid environments or spaces with high particulate matter, where your ion generator's performance noticeably decreases. If you're using it alongside air conditioning, you're likely experiencing even less effectiveness. Research indicates female users report issues more frequently with underperforming ion generators.

The device won't help with gases, odors, or larger particles like pollen and house dust allergens, leaving these common irritants in your air.

When you see particles collecting on surfaces around your ion generator, don't assume it's working properly – this is actually a sign of the device's limitations.

Without a mechanical filtration system, you're just moving contaminants around rather than removing them. Plus, if you haven't been cleaning your unit frequently, its already limited efficiency has likely decreased further.

Power Supply Troubleshooting Steps

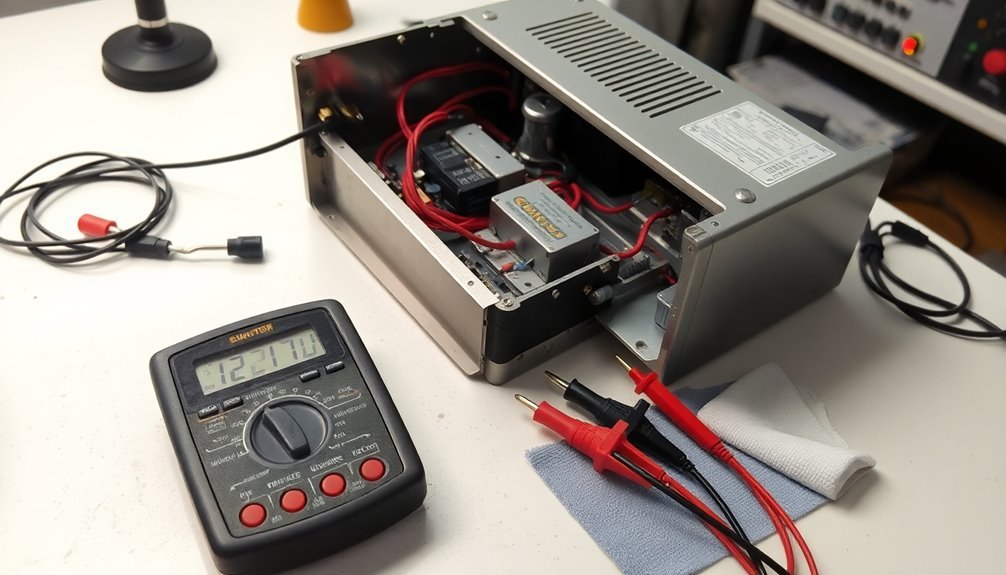

A reliable power supply forms the backbone of any ion generator's performance. When your unit isn't working properly, checking the power supply should be your first step. You'll need a multimeter and basic safety knowledge to diagnose common issues effectively. The proper voltage should be 220V/50Hz for optimal operation.

Start by ensuring your unit is completely powered off and unplugged. Check the power fuse first – a blown fuse often indicates deeper problems that need addressing. It's crucial to inspect for any burned-out components when checking the power supply. Next, use your multimeter to measure voltage outputs at key points, particularly the high-voltage capacitor and secondary coil of the high-frequency transformer.

| Component | What to Check | Common Issues |

|---|---|---|

| Power Fuse | Visual inspection | Blown, discolored |

| Rectifier Diodes | Voltage readings | No output, unstable voltage |

| Capacitors | Physical condition | Bulging, leakage |

| Transformer | Secondary coil | No high-voltage output |

| Circuit Board | Connection points | Short circuits, loose wires |

If you discover issues with specific components, replace them using manufacturer-approved parts. Remember to check for short circuits throughout the power supply circuit board, as these can cause recurring problems. Always consult your manufacturer's guidelines for specific troubleshooting procedures and safety protocols before attempting repairs.

Environmental Factors Affecting Performance

Your ion generator's performance depends heavily on environmental conditions, including humidity levels that affect static control and overall efficiency.

Multiple ion generators working together can boost efficiency significantly, as research shows increasing units from two to four improves performance by up to 8%.

The temperature in different areas of your space will influence how effectively ions are distributed and maintained in the air. Fine particles PM2.5 can significantly reduce your generator's efficiency if they accumulate in high concentrations.

You'll get the best results by ensuring proper airflow throughout the room, avoiding stagnant air pockets that can reduce the unit's effectiveness.

Humidity and Static Control

Environmental moisture levels play a crucial role in your ion generator's performance and static control capabilities. You'll notice peak performance when relative humidity stays between 40-60%, as this range allows for effective negative ion generation while maintaining proper static control.

When humidity rises above this range, your generator's efficiency drops because water droplets absorb the ions, reducing their lifespan and density. Negative ions typically have a 20-30 second lifespan before dissipating into the atmosphere. The application of −90 kV voltage to wire electrodes helps maintain optimal ion generation even in challenging humidity conditions.

In low-humidity environments, you'll experience more static electricity issues, as dry air prevents electrical charges from dissipating naturally. While this might make your ion generator's effects more noticeable, it's not optimal for overall performance. Your generator works best when it can balance ion production with natural moisture levels.

- Picture water molecules dancing through the air, creating invisible bridges for static electricity to flow away

- Visualize ions being absorbed by suspended water droplets like tiny sponges in the atmosphere

- Think of static electricity building up like an invisible blanket on plastic surfaces in dry conditions

Remember that your ion generator's effectiveness in removing airborne pollutants decreases in high-humidity conditions. If you're using ionization for air purification, you'll want to maintain moderate humidity levels for the best results.

Temperature Impact Zones

Temperature fluctuations create distinct impact zones that influence ion generator performance in surprising ways.

While you might expect consistent effects from temperature changes, the reality is more complex. Your ion generator's effectiveness can vary considerably across different temperature ranges, and there's no universal "ideal" temperature for optimal performance.

You'll notice the most considerable temperature impacts in three distinct zones: low (14-17°C), medium (23-27°C), and high (39-51°C). Each zone affects your device's ability to generate negative ions and remove particulate matter differently.

What's particularly challenging is that temperature inversions, especially at night, can trap pollutants near the ground and interfere with your generator's ion distribution.

To get the best results from your ion generator, you'll need to evaluate your local temperature patterns. If you're operating in an area with frequent temperature inversions or extreme temperature variations, you might need to adjust your device's placement or operating times.

Remember that vertical temperature profiles in your space can considerably impact how effectively ions disperse, so evaluate mounting height and air circulation patterns when positioning your unit.

Airflow Quality Requirements

Achieving perfect ion generator performance boils down to maintaining proper airflow quality in your environment. Your ion generator relies heavily on consistent, laminar airflow to deliver ions effectively to their target.

When you're dealing with non-linear airflow conditions, you'll notice significant variations in ionizer balance and discharge times, which directly impact your system's effectiveness.

To overcome airflow challenges, you'll need to evaluate using compressed dry air (CDA) or nitrogen (N2) as delivery gases. These gases help create a calibrated flow that can overcome chamber airflow inconsistencies.

Remember that even small differences in airflow velocity can affect ion movement and balance across different areas of your workspace.

- Picture a gentle stream of water flowing smoothly across a flat surface – that's your ideal laminar airflow

- Imagine leaves swirling erratically in different directions – that's problematic non-linear airflow you need to avoid

- Think of a perfectly aimed garden sprinkler creating an even spray pattern – that's your best ion distribution

Your mounting location and airflow direction are vital factors. Position your ion generators at the supply fan inlet, ensuring air flows simultaneously between the carbon fiber needles for the best possible ion distribution.

Maintenance and Cleaning Protocols

Proper maintenance stands as the cornerstone of reliable ion generator performance. You'll need to establish regular maintenance intervals based on your specific environment, with critical clean rooms requiring checks every six months.

Don't skip testing your ionizer with a charged plate monitor or test kit to verify it's functioning correctly.

When cleaning emitter points, you'll want to use isopropyl alcohol (IPA) and a cleanroom-safe swab. Gently rotate the swab around each point to remove contamination, being careful not to bend or break them.

Let the IPA dry completely before reassembly to prevent damage to your equipment.

For general cleaning, you should use an ESD-safe vacuum or brush to remove dirt from the fan and electrical components. Clean the filter housing with canned air or water, verifying it's completely dry before putting it back.

Wipe the case using a soft cloth with deionized water or an IPA mixture.

Always disconnect power and de-energize the emitter pins before starting any maintenance work.

You'll need to use ESD-safe cleaning tools to prevent static discharge damage, and handle those sharp emitter points with care to avoid injury.

Component Testing and Replacement

When testing ion generator components, you'll need to focus on two critical measurements: offset voltage and discharge time. Using a charge plate monitor (CPM), set it to Decay/Offset mode with ±1 KV starting charge and ±100 Volts stopping charge. Your offset voltage shouldn't exceed ±35 volts per industry standards, while discharge times must meet your specific requirements.

If you're experiencing issues, start troubleshooting by checking these common problem areas:

- Emitter points covered in dark, fuzzy buildup that's blocking ion flow

- Airflow vents clogged with dust and debris

- Power supply connections loose or damaged

When replacing components, you'll need to follow the manufacturer's guidelines strictly. Don't attempt to use incompatible parts, as this can damage your unit or create safety hazards.

After replacing any component, always conduct a full test of both offset voltage and discharge time to guarantee proper function.

Remember to power off your unit before any component replacement and wear appropriate safety gear. If you're unsure about any testing or replacement procedure, consult your ionizer's operating manual or contact the manufacturer for guidance.

Grounding and Static Control

Effective grounding and static control are essential safeguards for your ion generator's performance and longevity. You'll need to verify proper grounding methods to prevent electrical hazards and protect your device from damaging static discharge.

For portable ion generators, your unit's frame can serve as the ground point, but you must confirm that all equipment is properly connected to this reference point. Don't rely on floating ground systems, as these aren't desirable and can compromise safety. Instead, implement a single-point ground (SPG) system where all circuit commons connect to one chassis point.

When handling your ion generator's components during maintenance, you'll need proper static control measures. Always wear a grounding wrist strap connected to a reliable ground point.

Don't make the mistake of thinking that simply touching a grounded mat or using ionization alone will protect against static discharge – these methods aren't effective. For additional protection, consider using foot grounding devices or grounded garments if you're working in a sensitive environment.

Remember to test your grounding connections regularly using a ground/neutral continuity tester to verify low resistance connections are maintained throughout the system.

Safety and Operating Guidelines

To protect your health when using an ion generator, you'll need to place the unit in an unoccupied space and guarantee proper ventilation to minimize exposure to potentially harmful ozone and VOCs.

You should always wear protective gloves when handling the unit's internal components during maintenance to avoid contact with hazardous materials and electrical parts.

Keep your ion generator away from moisture and inspect power cords regularly for damage, as these devices can pose electrical hazards if not properly maintained.

Essential Protection Measures

In accordance with safety standards, ion generators require specific protective measures to guarantee both user safety and peak performance.

You'll need to verify that your device has proper quality certification, especially if it produces over 55,000 ions per cubic centimeter, as these units require medical certificates. It's essential to operate your generator in an environment with humidity levels between 45-75% and keep windows and doors closed during use.

To protect yourself and your equipment, implement these necessary safety practices:

- Keep the device in a secure location away from children and pets, treating it with the same caution you'd use for any high-voltage electrical equipment.

- Monitor for unusual odors that could indicate excessive ozone production from worn ionizing needles.

- Place the unit at least one meter away from where you spend most of your time, ensuring proper ion distribution.

Never attempt DIY repairs on your ion generator, as the internal components carry dangerous voltage levels.

Regular maintenance, including filter changes and needle cleaning according to manufacturer specifications, will help prevent safety issues and maintain ideal performance.

Use your ionizer in conjunction with air purifiers for the best results, but don't exceed recommended operating times.

Handling Hazardous Components

Despite their benefits, ion generators contain potentially hazardous components that require careful handling and strict safety protocols. When handling these devices, you'll need to protect yourself from chemical byproducts, particularly ozone and formaldehyde, which can cause respiratory issues and other health problems.

Always guarantee proper ventilation when operating your ion generator to prevent the buildup of harmful VOCs and ultrafine particles. If you're experiencing symptoms like headaches, throat irritation, or breathing difficulties, immediately turn off the device and ventilate the area. Don't ignore these warning signs, as prolonged exposure can lead to more serious health issues.

When maintaining your ion generator, handle internal components with care, especially if your model contains radioactive materials for ion generation. You'll want to select devices that meet safety standards and produce minimal ozone emissions.

If you're unsure about proper handling procedures, consult the manufacturer's guidelines or seek professional assistance. Remember to dispose of old units properly through authorized channels to prevent environmental contamination.

Frequently Asked Questions

Can I Use My Ion Generator With Different Types of Solvents?

You shouldn't use any solvents with your ion generator, as they're incompatible and can cause serious damage. Concentrated acids and organic solvents like hexane or benzene are especially dangerous for these devices.

How Often Should Calibration Be Performed on an Ion Generator System?

You should calibrate your ion generator every 6 months according to JESDD625-A standards. If you notice significant drift or use it in harsh environments, you'll need more frequent calibrations to maintain accuracy.

What's the Typical Lifespan of an Ion Generator Before Replacement?

You'll typically need to replace your ion generator after about 2 years or 17,500 hours of continuous use. With proper maintenance, it could last up to 26 months, but performance may decline after this period.

Will Installing Multiple Ion Generators in Series Improve Performance?

While you can install multiple ion generators in series, it's not always beneficial. You'll need to space them properly and guarantee they're compatible with your system's airflow to avoid performance interference.

Can Temperature Fluctuations in Storage Affect Future Ion Generator Functionality?

Yes, temperature fluctuations during storage can harm your ion generator's future performance. Extreme temperatures may damage electronic components and membranes, reducing efficiency. You'll want to store it at stable, room-temperature conditions.

In Summary

If your ion generator still isn't working after trying these solutions, don't hesitate to consult a professional technician. You'll want to maintain regular cleaning schedules, guarantee proper grounding, and monitor environmental conditions to prevent future issues. Remember, you're dealing with electrical equipment, so always prioritize safety. With proper care and attention to these tips, you'll keep your ion generator running efficiently.

Leave a Reply