Pink anti-static foam protects your sensitive electronics in seven key ways. You'll benefit from its effective static charge dissipation, preventing harmful ESD damage. The foam's closed-cell structure offers superior shock absorption and cushioning, while its cleanroom-safe materials keep your components contaminant-free. You're getting an eco-friendly packaging solution that's fully customizable to your specific needs. The foam's impressive moisture and chemical resistance adds another protective barrier, and its cost-effective nature makes it perfect for short-term storage. These features work together to create a complete protection system that's worth exploring further.

Effective Electrostatic Charge Dissipation

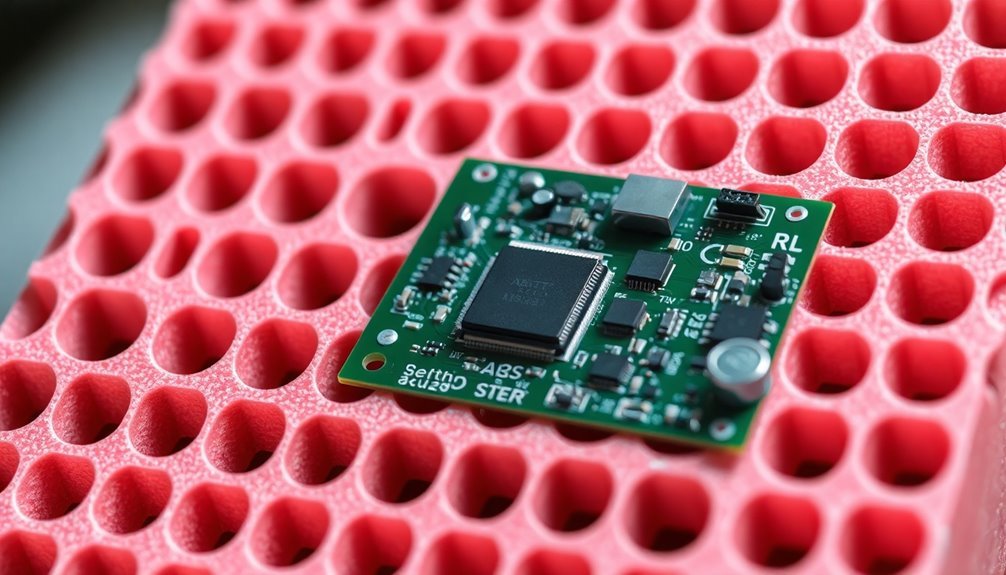

Anyone working with sensitive electronics knows the critical importance of electrostatic charge dissipation. Pink anti-static foam serves as your first line of defense against potentially damaging static charges that can harm delicate components.

You'll find this specialized foam prevents static buildup through its unique surface properties, enhanced by anti-static additives and surfactants. The material's polyethylene foam composition makes it both durable and cost-effective for protective packaging needs.

When you're handling electronic components, the foam actively dissipates static charges that come from various sources – whether it's friction during transport, nearby components, or your own handling. The foam's closed-cell structure, combined with its anti-static properties, creates an effective barrier that protects your sensitive devices from electrostatic discharge events.

You'll need to verify you're using the foam within its designated shelf life to maintain the best protection. While it's excellent for temporary storage and shipping applications, you should consider more permanent solutions for long-term use.

The foam's thermoformable nature lets you customize it to fit specific components, but remember it's not suitable for lead insertion applications. Regular compliance verification is essential to confirm the foam maintains its ESD-protective properties throughout its use.

Superior Physical Shock Protection

Shock-protection capabilities make pink anti-static foam an essential safeguard for your sensitive electronic components. The closed-cell polyethylene structure provides superior cushioning while remaining lightweight and flexible, making it perfect for protecting your devices during handling, shipping, and storage.

When you're working with electronic components, you'll find pink foam offers exceptional protection in three key ways:

- It creates a non-abrasive, soft surface for your workbench, preventing scratches and damage while you handle sensitive parts.

- Its high-strength buffer properties absorb impacts and vibrations that could otherwise harm your electronics.

- The foam's closed-cell structure resists tears, punctures, and moisture, keeping your components safe from environmental threats.

You'll appreciate how easily you can customize this foam through die-cutting and laminating to create precise fits for your specific devices. The foam's surface resistance range of 10^6 to 10^11 ohms ensures optimal static discharge protection. While it's particularly effective for short-term applications, you should note that its protective properties may decrease over time.

For shipping purposes, you can rely on pink foam's excellent shock absorption to keep your electronics secure, while its moisture-resistant qualities guarantee protection even in varying environmental conditions.

Cleanroom Safe Materials

Beyond its protective properties, pink anti-static foam meets strict cleanroom requirements for electronics manufacturing. When you're working with sensitive electronic components in ISO-certified cleanrooms, you'll need materials that won't introduce contaminants or compromise the controlled environment.

Pink anti-static foam is specifically designed to comply with stringent cleanroom standards, from Class 1 to Class 6 facilities. HEPA filtration systems maintain the foam's cleanliness throughout storage and use.

You'll find that this specialized foam aligns with cleanroom material requirements, as it's made from virgin resins and doesn't contain animal-derived substances or surfactants that could contaminate your electronic components. It's particularly valuable because it protects against particles as small as 0.5 microns, which can severely damage electronic parts.

The foam's anti-static properties also prevent electrostatic discharge, a vital feature in cleanroom environments where static electricity must be strictly controlled.

When you're selecting materials for your cleanroom, you'll need to verify they're ISO-certified and compatible with cleanroom protocols. Pink anti-static foam meets these requirements while maintaining the positive pressure environment between 15Pa and 45Pa that's essential for electronics manufacturing facilities.

Environmentally Friendly Packaging Solution

Within today's environmentally conscious market, pink anti-static foam is evolving alongside sustainable alternatives. Modern packaging solutions are increasingly incorporating eco-friendly materials to meet the growing demand from environmentally conscious consumers, who are willing to pay more for sustainable options.

These sustainable options include:

- Cornstarch-based foam materials that provide protective qualities while remaining fully biodegradable and compostable

- PaperFoam Plus solutions that integrate seamlessly with existing paper recycling systems

- Cruz Foam products made from upcycled food waste, contributing to a circular economy

You're now able to choose packaging solutions that align with your environmental values without compromising on protection. These alternatives help reduce your carbon footprint while ensuring your electronics remain safe from static discharge and physical damage. Recent testing has verified these alternatives as high-performing protective packaging for sensitive electronics.

As regulations continue to evolve and consumer preferences shift toward sustainable options, you'll see more eco-friendly pink foam alternatives entering the market, offering both environmental benefits and reliable protection for sensitive electronic components.

Customizable Protection Options

Custom die-cut foam inserts let you create precise compartments for your specific electronic components, ensuring each part stays firmly in place during transport and storage.

You'll find that combining multiple layers of protective foam creates an additional safety barrier, with each layer serving a distinct protective purpose.

Whether you're shipping delicate circuit boards or storing valuable electronic equipment, these customizable foam solutions give you complete control over the level of protection your items receive.

The egg-crate design of convoluted foam provides efficient impact absorption for maximum protection of sensitive items.

Die-Cut Inserts For Parts

Versatile die-cut foam inserts provide essential protection for your electronic components through precise customization options. You'll find various foam types available, including EPE, EVA, PE, and PU foam, each offering specific protective qualities for your sensitive equipment. When you're dealing with electronics, anti-static foam options become particularly vital to prevent damage from static electricity. These materials are engineered with excellent vibration dampening properties.

The customization process allows you to create perfectly fitted inserts that cradle your components securely.

- Precision-cut cavities that match your product's exact dimensions, guaranteeing a snug fit

- Multiple compartment designs that can house different components within the same container

- Varied foam densities and thicknesses tailored to your specific protection requirements

Your electronic parts will stay protected against impacts, vibrations, and scratches during storage or transit. Whether you're securing laptops, cameras, or delicate circuit boards, die-cut foam inserts offer superior shock absorption and dampening properties.

You can also enhance your product's presentation while maintaining lightweight protection. The combination of precise cutting techniques and advanced machinery guarantees you'll get exactly the protection your electronic components need, without compromising on security or accessibility.

Multi-Layer Protection Solutions

Multi-layer protection solutions elevate your electronics' safety through strategically combined materials and customizable configurations. You'll find various density options ranging from 2 to 6 lbs. pcf in anti-static polyurethane foams, allowing you to select the perfect level of protection for your specific needs. When you combine pink polyethylene foam with other cushioning materials, you're creating a thorough shield against multiple threats. The Faraday Cage effect provides additional electromagnetic interference protection when using these materials together.

| Protection Type | Benefits | Applications |

|---|---|---|

| Impact & Vibration | Shock absorption, cushioning | Transportation, Storage |

| ESD Protection | Static dissipation, charge control | Electronic Components |

| Environmental | Weather resistance, contamination prevention | Long-term Storage |

You can enhance your protection strategy by incorporating conductive materials with carbon black, which provides superior defense against electrostatic discharges. The foam's custom-cut capability means you're not limited to standard sizes – you can shape it precisely to fit your electronic components. For maximum effectiveness, you'll want to combine different protection methods, such as using convoluted egg-crate designs for impact absorption while maintaining anti-static properties. The closed-cell structure of polyethylene foam adds water resistance, while non-sloughing polyurethane prevents contamination risks.

Moisture and Chemical Resistance

When protecting sensitive electronic components, pink ESD polyethylene foam stands out for its exceptional resistance to both moisture and chemicals.

You'll find this material offers robust protection with its 98% recovery rate and impressive compressive strength of 2.9-3.5 kg/cm². The foam's non-corrosive and non-sloughing properties guarantee your electronics remain contamination-free while maintaining consistent performance across diverse environmental conditions. The manufacturer presents these specifications in a bulleted format to enhance readability and quick reference.

You can rely on pink foam's extensive protection through these key features:

- Water damage prevention with moistureproof properties that shield your components from humidity and bacterial growth

- Chemical resilience that matches traditional EPE foam, protecting against harmful chemical exposure while maintaining a surface resistivity of 10^8-11 Ω/square

- Versatile application potential across electronics, automotive, and precision instrument industries, with customizable solutions for specific component needs

The foam's compliance with ANSI/ESD S20.20 and S541 standards guarantees you're getting reliable protection that meets industry requirements. Whether you're working in high-humidity environments or dealing with potential chemical exposure, pink foam's density of 18-28 kg/m³ provides the perfect balance of protection and functionality.

Cost-Effective Short-Term Storage

Beyond its protective qualities, pink foam stands out as a cost-effective storage solution for your electronic components. You'll find its lower material costs and versatile customization options make it an economical choice for short-term storage needs. When you're shipping sensitive electronics, you can cut the foam to exact specifications, eliminating waste and reducing overall packaging expenses.

| Cost Factor | Benefit |

|---|---|

| Material Cost | Lower than alternative ESD materials |

| Customization | Reduces waste through precise cutting |

| Damage Prevention | Minimizes replacement and return costs |

Pink foam's single-trip usage perfectly suits your temporary storage and shipping requirements. You'll appreciate how it combines cushioning protection with static dissipation, ensuring your components arrive safely while keeping your packaging costs in check. By preventing static-related damage and mechanical shocks, you're reducing product rejects and avoiding costly returns. The foam's ability to be custom-cut means you won't waste material on standardized sizes that don't fit your specific needs. When you need reliable, cost-effective protection for your electronic components during short-term storage or shipping, pink foam delivers both practical protection and economic value.

Frequently Asked Questions

How Long Can Pink Foam Maintain Its Anti-Static Properties in Storage?

You'll find that pink foam's anti-static properties typically last up to one year in storage, but it's best to test regularly as humidity, handling, and environmental conditions can substantially affect its effectiveness.

Can Pink Foam Be Safely Reused for Multiple Shipping Cycles?

You shouldn't reuse pink foam for multiple shipping cycles as its antistatic properties degrade within 6 months. It'll also lose cushioning effectiveness, and repeated handling can compromise both physical integrity and ESD protection.

What Temperature Range Can Pink Anti-Static Foam Withstand Before Degrading?

You can safely use pink anti-static foam up to 70°C (158°F) before risking degradation. While it's thermally stable, you'll want to avoid exposing it to temperatures beyond this maximum operating range.

Does Exposure to UV Light Affect Pink Foam's Protective Properties?

You don't need to worry about UV exposure affecting your pink foam's protective properties. The foam's closed-cell structure and chemical composition maintain its anti-static and cushioning capabilities even when exposed to UV light.

How Does Humidity Affect the Performance of Pink Anti-Static Foam?

High humidity rapidly saturates your pink anti-static foam's surfactants, reducing its protective properties. You'll notice it's less effective over time, while low humidity extends its shelf life and maintains performance longer.

In Summary

You'll find pink antistatic foam is your ideal solution for protecting sensitive electronics. It effectively dissipates static, absorbs impacts, and maintains cleanroom standards while being eco-friendly. Whether you need custom-cut pieces or moisture-resistant storage, this versatile material delivers reliable protection at a reasonable cost. Don't risk damaging your valuable components – choose pink foam for complete peace of mind.

Leave a Reply