Maintain your workspace humidity between 40-60% RH to protect sensitive electronics from moisture damage and static electricity. You'll want to invest in a reliable humidity monitoring system with real-time alerts to track sudden changes that could harm your equipment. Install adaptive humidity control systems, like humidifiers or dehumidifiers, that automatically respond to seasonal fluctuations and keep conditions stable. While these basic steps will get you started, proper humidity management involves several other key factors that can substantially extend the life of your electronic components.

Monitor Your Workspace Environment

Set up consistent dashboards and alerts to track performance metrics.

Monitor your digital workspace deployments with purpose-built solutions since traditional monitoring tools may not provide adequate coverage.

Regularly audit your monitoring systems to guarantee they're functioning correctly.

Remember to limit access to monitoring data to authorized personnel only, maintaining a balance between operational needs and privacy considerations.

Control Seasonal Humidity Changes

To maintain ideal conditions, you'll need to keep humidity levels between 40% and 60% RH, but you'll need to adjust these targets based on your local climate. If you're in a naturally dry area, aim for slightly higher levels, while humid regions require additional dehumidification measures.

Install an adaptive humidity control system that automatically responds to seasonal fluctuations. You'll benefit from real-time monitoring capabilities that alert you to sudden changes before they affect your work.

Don't forget to maintain your humidity control equipment regularly and train your team on proper seasonal management practices. Water vapor infiltration can compromise even the most robust electronic systems.

Watch your local weather patterns closely, as they'll directly impact your indoor environment. During summer months, focus on preventing condensation issues, while in winter, pay extra attention to static electricity risks.

Regular system audits will help you identify and address any gaps in your humidity control strategy.

Choose Effective Control Methods

Three key control methods stand out for maintaining precise humidity in your electronics workspace: integrated climate systems, dedicated humidifiers/dehumidifiers, and desiccant solutions. You'll need to select the right combination of these methods based on your specific needs and environment.

Modern integrated systems offer real-time monitoring and automatic adjustments, while standalone humidifiers and dehumidifiers provide targeted control in smaller spaces. For extra protection, you can deploy desiccants in storage areas or equipment cabinets. Maintaining humidity at 40% relative humidity helps prevent static electricity buildup and discharge.

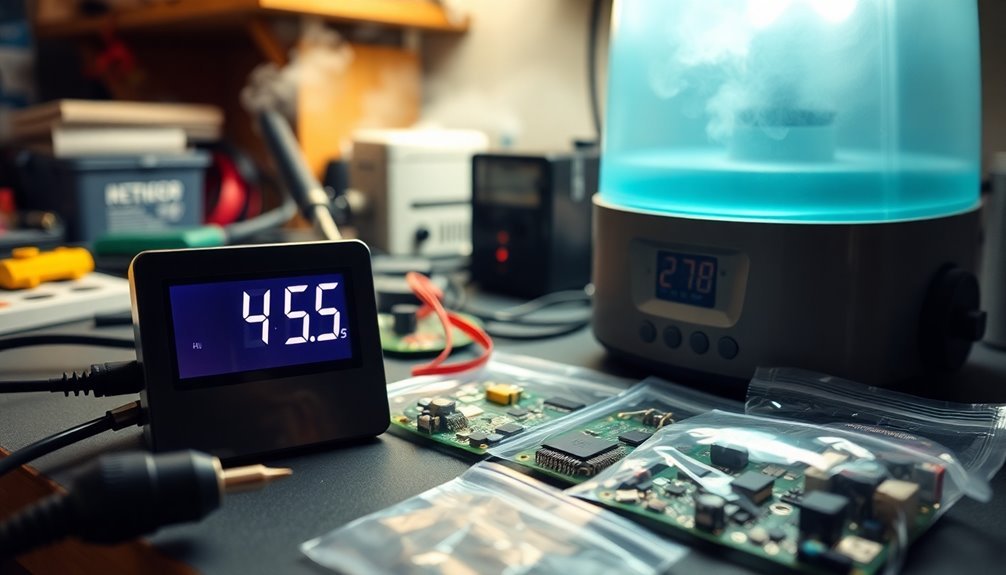

To visualize effective humidity control in action, consider these setup examples:

- A central monitoring station with digital displays showing real-time humidity readings across different work zones

- Wall-mounted humidifiers with built-in hygrometers strategically placed near sensitive electronics workbenches

- Sealed storage cabinets containing silica gel packets for moisture-sensitive components

- Portable dehumidifiers positioned near entrance ways to combat incoming moisture

- Clear plastic bins with humidity indicators for storing PCBs and components

You'll achieve the best results by implementing a layered approach, combining these methods to maintain humidity between 40% and 60% RH.

Regular maintenance of your control systems guarantees consistent performance and protects your electronic components from moisture-related damage.

Frequently Asked Questions

How Does Humidity Affect the Lifespan of Stored Electronic Components?

High humidity can drastically reduce your components' lifespan through moisture absorption, causing corrosion, electrical shorts, and material degradation. You'll see faster deterioration when components aren't stored between 40-60% relative humidity.

Can Rapid Humidity Changes Damage Electronics More Than Constant High Levels?

Yes, your electronics are typically more vulnerable to rapid humidity changes than constant high levels. They'll face increased risks of condensation, short circuits, and corrosion when exposed to sudden moisture variations in the environment.

What Humidity Indicators Are Most Reliable for Home Electronics Workspaces?

You'll find digital hygrometers most reliable for home electronics work. Place them 3.5 feet above ground and consider AGM's Electronic Humidity Sensor if you need data logging capabilities and long-term monitoring.

How Long Should Electronics Acclimate When Moving Between Different Humidity Environments?

You'll need 15-50 minutes depending on the temperature difference. For every 5°F change, add 3 minutes if boxed and 7 minutes if unboxed. Higher humidity requires longer acclimation times.

Do Different Types of Circuit Boards Require Different Optimal Humidity Levels?

Yes, you'll need different humidity levels based on your board type. Semiconductor assembly works best at 35-45% RH, while PCB assembly needs at least 30% RH. Components with MSL ratings require 40-60% RH.

In Summary

Keep your electronics workspace at ideal humidity levels by regularly monitoring conditions and addressing seasonal changes. You'll prevent damage to sensitive components and maintain consistent performance of your equipment. Whether you're using a dehumidifier, humidifier, or climate control system, you're taking essential steps to protect your investment. Don't forget to check humidity levels daily and adjust your control methods as needed.

Leave a Reply