You'll need to follow specific industry regulations when using static storage containers, whether for temporary or permanent purposes. These requirements include zoning compliance (typically 60 days without a permit), proper setbacks (20-50 feet from property lines), and adherence to building codes like IBC and IRC. You must guarantee regular safety inspections, maintain structural integrity, and implement secondary containment systems for certain materials. Environmental protection measures, professional certifications, and ongoing maintenance are also essential. Understanding these thorough standards will help you navigate the complex landscape of storage container requirements.

Understanding Static Storage Regulations

While static storage containers offer flexible storage solutions, they come with specific regulatory requirements that vary by location and intended use.

You'll find that these containers are generally permitted in any zoning district for up to 60 days without a permit when used for moving or temporary storage purposes.

If you're using containers in commercial or industrial areas, you're allowed a 60-day period for loading and unloading household or office contents. Containers must comply with the International Building Code for safety and structural integrity.

For construction sites, you'll need a building permit, and you can use the containers for up to 180 days, with possible extensions available.

When placing your container, you must guarantee it doesn't exceed 10 feet in height and occupies no more than 10% of the required yard area.

You'll need to maintain specific setbacks: 20 feet from side or rear lot lines without adjoining residential property, 50 feet when adjacent to residential areas, and 10 feet from the main building.

If you're storing oil in containers with a capacity of 55 gallons or more, you must provide secondary containment that can hold the entire capacity of the largest container.

Regular inspections are mandatory to guarantee compliance with safety standards and detect potential issues.

Key Industry Standards

When you're working with static storage containers, you'll need to understand two primary industry standards: API 653 and STI SP001.

API 653 outlines core requirements for the inspection, repair, alteration, and reconstruction of above-ground storage tanks. This standard, developed by the American Petroleum Institute, focuses on the safety and integrity of aboveground storage tanks (ASTs) built to API 650 or API 12C requirements. Similar to IMO safety regulations, these standards specify procedures for conducting periodic inspections, repairs, and adjustments to keep these tanks in good working order and reduce the danger of leaks, corrosion, and structural failures. API 653 emphasizes corrosion avoidance, tank foundation maintenance, and structural integrity control.

STI SP001 complements these regulations by providing specific testing protocols for shop-fabricated tanks and small field-erected tanks. The Steel Tank Institute's SP001 Inspection Standard deals directly with above ground storage tanks (ASTs), up to 30 feet in diameter and 50 feet tall. However, this standard is most commonly utilized in the inspection of carbon steel shop fabricated tanks ranging from 1,000 gallons to 30,000 gallons. These parameters cover a great deal of tanks within the industry. Because of this, STI SP001 is a highly utilized inspection standard for ASTs developed to provide an alternative inspection standard to API 653. The STI SP001 standard allows for a less stringent and more relevant inspection procedure to be followed when inspecting shop fabricated tanks, small field erected tanks not built to API 12C or 650, and portable containers.

STI SP001 also determines inspection frequency based on the type of product being stored, the volume of product stored, and the tank's ability to withstand the probable error that could occur. To determine the inspection intervals, tanks are broken down into three different categories: Class #1, Class #2, and Class #3, where Class #3 holds the greatest risk potential. The greater the risk potential, the greater the inspection frequency.

Inspection Frequency is determined by:

- Category 1: ASTs with Spill Control and CRDM

- Category 2: ASTS with Spill Control, and without CRDM

- Category 3: ASTs without Spill Control

Inspections include:

- P = Period Inspection (Monthly)

- E = External Inspection

- L = Leak Test

- I = Internal Inspection

A popular inspection technique for small ASTs and USTs is performing a Pressure Leak Test. This type of test must be performed very carefully as it forces air into the tank causing pressure to build within. This contained pressure (Psig) allows for an inspector to determine if a tank has a small leak that could potentially turn into a large leak. A leak test is performed once a tank is empty of product, pressurized to 3-5 PSI, and closely monitored for minute drops in pressure. It requires certified gauges capable of detecting drops in pressure as small as 1/10 of a PSI, as well as a collection of fittings, valves, and regulators for the specific tank and its nozzle requirements.

API 653 Core Requirements

One of the most essential standards in static storage container maintenance is API 653, which governs the inspection, repair, and alteration of steel aboveground storage tanks. You'll need to guarantee compliance with this standard if your tanks exceed 50 feet in height or 30 feet in diameter. Non-destructive testing methods are crucial for evaluating tank integrity and structural stability.

Under API 653, you're required to conduct inspections every 5 years by a licensed inspector, with internal inspections occurring every 10 years or more frequently based on initial assessments. You'll need to employ various testing methods, including ultrasonic, magnetic particle, and vacuum box testing, to maintain integrity.

| Critical Aspects | Requirements | Your Action Needed |

|---|---|---|

| Documentation | Complete Records | Maintain detailed inspection logs |

| Testing Methods | Multiple Types | Implement thorough testing plan |

| Inspection Timing | 5-10 Year Intervals | Schedule regular assessments |

When you're managing storage tanks, you'll need to follow API 653's guidelines for thickness testing, settlement data collection, and structural integrity assessment. The standard works in conjunction with API 650, guaranteeing your maintenance and repairs align with original construction specifications. You must document all inspections, repairs, and alterations thoroughly, referencing API 650 specifications to maintain compliance and safety standards.

STI SP001 Testing Protocols

The STI SP001 standard complements API 653 by providing specific testing protocols for smaller storage containers. You'll find it applies to welded steel tanks up to 30 feet in diameter and 50 feet tall, typically ranging from 1,000 to 30,000 gallons.

When you're implementing STI SP001 testing, you'll need to follow a structured process. First, verify you're working with certified inspectors who've passed the required examinations and maintain current certifications. These professionals must understand both safety protocols and inspection schedules. Inspectors must complete recertification every 5 years to maintain their qualifications.

Your testing frequency will depend on your tank's classification (#1 to #3), with Class #3 requiring the most rigorous oversight due to higher risk potential.

For internal inspections, you'll need to properly clean the tank and use explosion-proof equipment. If you're dealing with tanks under 30,000 gallons without easy internal access, you can opt for leak testing at 3-5 PSI.

You must maintain detailed records using SP001 AST checklists and documentation. Remember, if you're conducting internal inspections, you'll need confined space entry certification and appropriate safety equipment to comply with OSHA regulations.

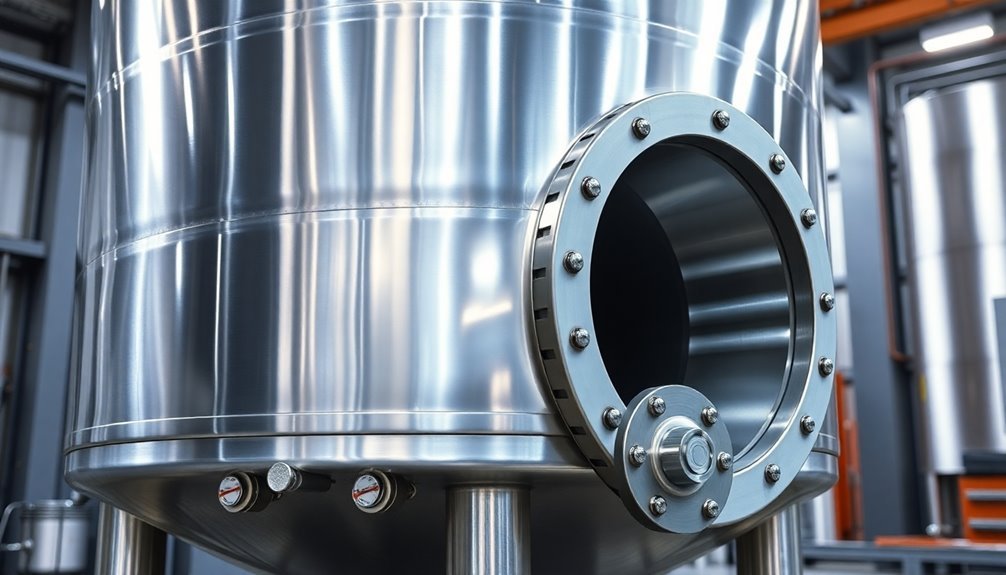

Container Types and Applications

Static storage containers come in diverse configurations to meet specific industrial and commercial needs. When you need versatile storage with frequent stock rotation, selective pallet racking containers offer the flexibility you're looking for, with their horizontal beam design and forklift accessibility. Custom metal fabrication can enhance these systems with tailored storage solutions.

Block stacking containers are ideal for low-turnover inventory, though they're limited in accessibility.

For specialized requirements, you've got multiple options. Drive-in racking maximizes storage density for homogeneous products, while push back racking implements LIFO rotation for perishable goods.

If you're handling fast-moving inventory, pallet flow racks and gravity flow systems provide efficient FIFO rotation through their sloped designs.

When it comes to liquid storage, you'll need to match your container type to your specific requirements. Static storage tanks handle non-hazardous liquids up to 100,000 liters, while polyethylene tanks work well for various industrial chemicals.

For corrosive materials, you'll want to evaluate fiberglass tanks, and for long-term storage needs, welded steel tanks offer reliable performance. Corrugated steel tanks provide an economical solution for rainwater collection and fire suppression systems.

Safety Testing Requirements

You'll need to follow strict testing protocols to guarantee your storage containers meet all safety and regulatory compliance standards.

Your testing program must include both visual inspections and non-destructive testing methods to establish baseline conditions and determine corrosion rates, as outlined in standards like API 653 and STI SP001.

Your containers must undergo regular integrity assessments by certified personnel who'll verify proper electrical grounding, foundation stability, and overflow protection systems to maintain operational safety. Storage containers must be placed on firm foundations capable of supporting their maximum intended loads.

Testing Protocols For Compliance

Four essential testing protocols govern the compliance requirements for static storage containers, each serving a distinct purpose in guaranteeing safety and reliability.

Under API Standard 653, you'll need to establish baseline inspections for tanks without prior records and conduct regular visual assessments. Load conditions must be thoroughly evaluated during inspections. A Professional Engineer's certification is required for approval.

EN 15635 requires you to test your static storage systems' load-bearing capacity and stability. You'll need to maintain detailed documentation of all inspections and perform regular maintenance checks to guarantee ongoing compliance with safety standards.

For dangerous goods storage, the TDG Act mandates specific testing procedures based on packing groups. You must conduct leak, drop, stacking, vibration, and hydrostatic tests, guaranteeing your containers display proper compliance marks and undergo periodic inspections.

When dealing with shipping containers under ISO 1496, you'll need to verify material specifications and structural integrity. You're required to test for leak-proofness and guarantee containers meet performance standards under various conditions. Don't forget to follow ISO 3874 guidelines for safe handling and securing methods during testing procedures.

Container Integrity Assessments

Building upon these testing protocols, container integrity assessments form the backbone of safety verification procedures. You'll need to guarantee your storage containers meet strict regulatory requirements outlined in USP <1207.1> and FDA guidelines.

These assessments are vital for preventing contamination and maintaining product stability through thorough testing methods. Regular testing throughout the product life cycle helps ensure consistent quality from development through commercial distribution.

You must implement deterministic testing procedures that provide quantifiable results through methods like vacuum decay and pressure decay tests. When you're conducting these assessments, you'll need to create positive controls using techniques such as laser-drilled holes to simulate natural defects.

It's essential that your validation protocols are specific to your container and closure system.

You're required to perform annual testing and inspections following industry standards like API Standard 653 and STI SP001 for aboveground storage containers. Your integrity testing methods must comply with SPCC regulations and be documented thoroughly.

Don't forget to maintain detailed records of your inspection and testing programs, including schedules and procedures. If you're working with containers that haven't been previously inspected, you'll need to establish baseline conditions before implementing regular assessment protocols.

Environmental Impact Guidelines

Environmental stewardship forms the cornerstone of modern static storage container management. You'll need to implement thorough secondary containment systems that can hold at least 10% of your total container volume or 100% of your largest container's volume, whichever is greater. These systems must prevent stormwater run-on and protect against environmental releases.

You're required to address spills and leaks promptly to maintain system integrity and prevent overflow situations. When designing your storage areas, you'll need to incorporate features that protect surrounding soil, groundwater, and air quality.

Don't forget that your storage tank systems must be professionally installed and certified to meet environmental protection standards.

To maintain compliance, you'll need to keep detailed records of your system's design and installation throughout its operational lifetime. You must also develop and implement emergency response plans before conducting your first product transfer.

Regular inspections are mandatory, and you'll need to verify your facility meets all applicable air emission standards. Remember that sustainable practices aren't just regulatory requirements – they're essential for reducing your facility's environmental footprint and energy consumption while protecting local ecosystems.

Inspection Protocols

In accordance with regulatory requirements, you'll need to establish thorough inspection protocols for all static storage containers. Your inspection program must include regular testing schedules, baseline evaluations, and specific techniques based on container size and configuration.

When implementing these protocols, you'll find that both visual inspections and non-destructive testing methods play vital roles in maintaining container integrity.

Your inspection program should incorporate these essential elements:

- Regular walk-around visual inspections to check for deterioration and potential discharges

- Baseline inspections to determine corrosion rates and establish future inspection intervals

- Non-destructive testing methods including hydrostatic, radiographic, and ultrasonic testing

- Detailed record-keeping of all inspections and test results for at least three years

You'll need to guarantee that qualified personnel conduct all inspections according to industry standards like API 653 and STI SP001. Your SPCC Plan must clearly identify the inspection protocol for each container and outline implementation procedures.

Remember to review and update your inspection program every five years, and maintain formal test records throughout each container's lifetime. For containers without prior records, you'll need to conduct an initial baseline inspection to establish their condition and suitability for continued service.

Material Selection Criteria

Material selection for static storage containers hinges on four critical factors: chemical resistance, physical durability, electrostatic safety, and regulatory compliance.

You'll need to evaluate each material's resistance to chemical corrosion and degradation. HDPE offers broad chemical resistance, while stainless steel excels with strong acids and alkalis. Carbon steel provides good corrosion resistance but requires regular maintenance to prevent rusting.

When considering physical durability, you're looking at a material's ability to withstand temperature changes and impacts. Stainless steel delivers superior durability, while fiberglass offers lightweight corrosion resistance despite its brittleness. HDPE presents a practical middle ground, suitable for both indoor and outdoor applications.

For electrostatic safety, you must guarantee your container prevents static buildup, especially for flammable liquids. You'll want materials with surface resistivity less than 1 x 10^5 ohms per square and volume resistivity below 1 x 10^3 ohm-centimeter per millimeter.

Don't forget to ground containers storing flammables.

Regulatory compliance can't be overlooked. You must match container specifications to material classification requirements, particularly for hazardous waste storage. Always guarantee proper marking and maintain strict compatibility between container materials and stored substances.

Regulatory compliance involves ensuring that the containers meet all relevant standards and regulations. This includes adhering to specific material classification requirements, especially for the storage of hazardous waste. Proper marking of the containers is also essential to ensure clear identification of the contents and the materials used. Maintaining strict compatibility between the container materials and the stored substances is crucial for safety and regulatory adherence.

Compliance Documentation Process

Establishing proper compliance documentation requires a systematic approach covering four essential components: design approval, certification, testing protocols, and regulatory submissions. You'll need to prepare detailed documentation showing arrangement, dimensions, maximum gross mass, and payload specifications, along with thorough material standards and corrosion protection details.

For successful compliance, you'll want to maintain these key records:

- Design documentation including scantlings of strength members, sling angles, and pad eye details

- Quality Assurance Plan with ISO certification requirements and inspection protocols

- Testing records showing NDT procedures, visual examinations, and prototype testing results

- Application documents including Service Request Forms (SRF) and type approval certifications

You must keep detailed records of your container's design and manufacture, including identification numbers and delivery dates. Don't forget to permanently affix the Safety Approval Plate with all required details.

Your documentation process should include regular updates of inspection records, testing protocols, and baseline condition assessments. Remember, a professional engineer needs to stamp design documents and supervise installation when required by regulations.

Make sure you maintain all records for the entire lifetime of your storage system.

Maintenance Best Practices

To maintain static storage containers effectively, you'll need to follow a thorough inspection and maintenance schedule that aligns with international safety standards.

Your initial container inspection must occur within five years of production, followed by inspections every 30 months thereafter. You'll also need to conduct visual checks every 60 days for signs of damage or deterioration.

Focus on preventative maintenance by addressing rust immediately to prevent moisture buildup. You should regularly lubricate hinges and doors while ensuring door seals remain wind and water tight.

If you're managing reefer containers, have trained professionals handle any repairs to maintain energy efficiency. Don't forget to check electrical and refrigeration units regularly.

Store your containers in locations protected from harsh weather conditions and place them on level surfaces with proper anchoring. You'll need to pay special attention to containers storing hazardous materials, keeping them separate and following EPA guidelines.

Remember to verify that your CSC safety approval plates are properly attached and display current inspection dates. When conducting inspections, document any modifications and check joints and metal regions for debris or damage.

Risk Assessment Methods

Several critical risk assessment methods must be implemented when managing static storage containers. You'll need to conduct thorough visual inspections to identify physical damage and assess material compatibility between containers and stored substances.

When evaluating risks, you must follow industry standards like API 653 and STI SP001, which provide specific guidelines for container inspection and testing procedures.

- Non-destructive testing methods, including ultrasonic testing and MFL scanning, help evaluate container integrity.

- Regular assessment of grounding systems and continuity testing prevents electrostatic discharge risks.

- Analysis of container age and service history provides essential data for risk evaluation.

- Evaluation of work environment conditions helps identify areas with high ESD potential.

You'll need to document all inspection findings and maintain detailed records of testing schedules as required by SPCC regulations. When dealing with flammable materials, you must comply with specific standards like EN 14470-1 for safety storage cabinets.

Remember that any deviations from industry standards require certification from a Professional Engineer who can verify environmental equivalency. Your risk assessment approach should integrate both physical inspection methods and electrical safety considerations to maintain thorough container safety.

Performance Monitoring Systems

Effective performance monitoring systems form the backbone of container management and operational reliability. You'll need to implement thorough monitoring strategies that combine host-level instrumentation with orchestration tools like Kubernetes to guarantee top-notch performance tracking.

Your monitoring setup should focus on key metrics including container health, application response times, and resource usage. You'll want to utilize transparent instrumentation that captures all essential data through a single point, while kernel tracepoints can provide detailed system call information without relying heavily on statsd metrics.

When selecting monitoring tools, you've got several powerful options. Prometheus paired with Grafana offers robust open-source solutions for metrics collection and visualization.

If you're looking for automatic discovery and advanced anomaly detection, Datadog provides real-time tracking with detailed insights. Sematext and Elastic Observability deliver integrated monitoring with customizable dashboards and machine learning capabilities.

To maximize effectiveness, you'll need to evaluate your environment's specific requirements. Whether you're running multi-cloud or hybrid setups, make sure your chosen tools support your infrastructure.

Implement sidecar containers for monitoring when needed, but be mindful of their resource impact and potential dependencies.

Frequently Asked Questions

How Long Do Static Storage Containers Typically Last Before Requiring Replacement?

You'll get 25-40 years from your static storage container with proper maintenance. If you've bought a second-hand container, expect 10-15 years, while new one-trip containers can last up to 40 years.

Can Static Storage Containers Be Stacked Safely During Transportation?

You can safely stack storage containers during transport by using proper locking mechanisms, following weight limits, and ensuring perfect corner alignment. Don't exceed five containers high, and always use appropriate securing equipment.

What Insurance Requirements Apply Specifically to Static Storage Container Facilities?

You'll need property insurance for facility damage, general liability for third-party claims, and customer goods legal liability coverage. It's also important to maintain loss of income and workers' compensation insurance.

Are There Special Considerations for Static Containers Used in Extreme Temperatures?

You'll need containers with verified temperature ratings, like Fibrestat ESD boxes that handle -60° to 250°F. Confirm they're made from glass-reinforced composites and test them regularly for surface resistivity and structural integrity.

How Do Static Storage Container Standards Differ Internationally Versus Domestic Requirements?

You'll find international standards like ISO and CSC are stricter than domestic requirements, with specific rules for dimensions, construction, and safety features. Domestic standards often vary by country and are less rigorous.

In Summary

You'll need to maintain strict compliance with static storage container standards to protect your assets and personnel. By following proper testing protocols, documenting compliance, and implementing regular maintenance schedules, you're ensuring operational safety and environmental responsibility. Stay current with industry regulations and perform consistent risk assessments. Remember, your container performance monitoring system's data will help you make informed decisions about system upgrades and replacements.

Leave a Reply